Magneto-rheological damper of automobile engine suspension system

A technology for automotive engine and mounting systems, applied in vibration suppression adjustment, non-rotational vibration suppression, etc., which can solve the problem of not meeting the vibration isolation requirements of high-speed engine mounting systems and effectively improving the high-frequency vibration isolation performance of vibration isolators , high-frequency vibration isolation performance of the vibration isolator is not ideal, etc., to achieve the effects of suppressing high-frequency dynamic hardening, broadening the vibration isolation frequency range, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

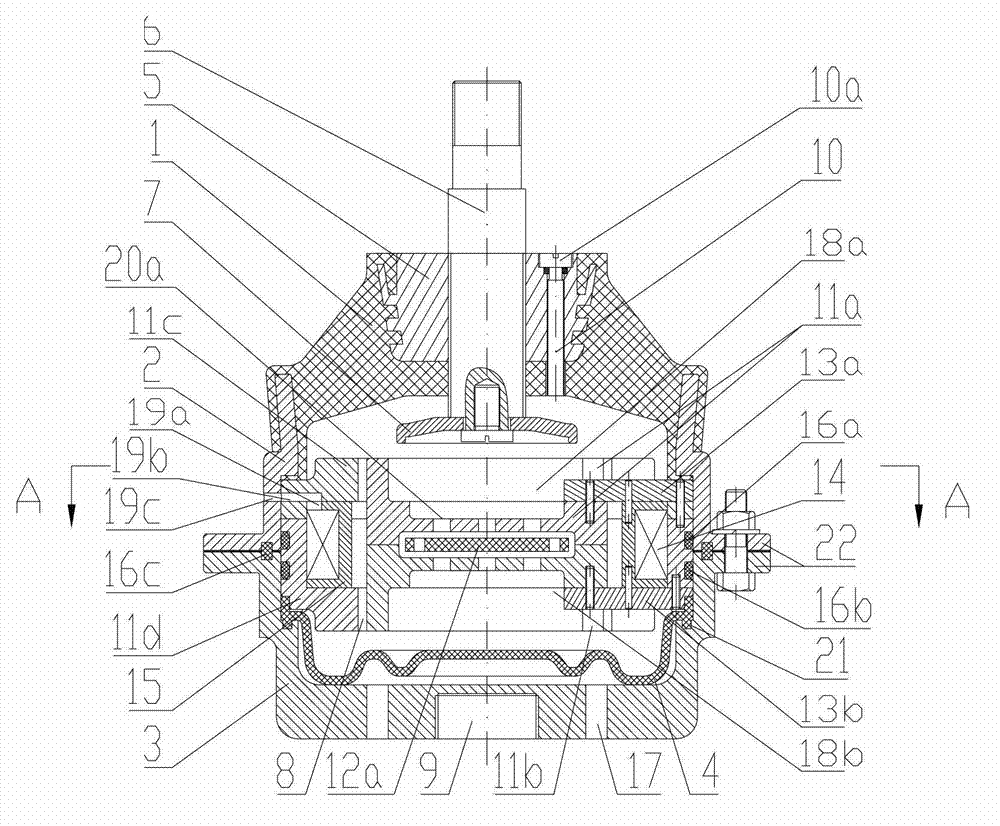

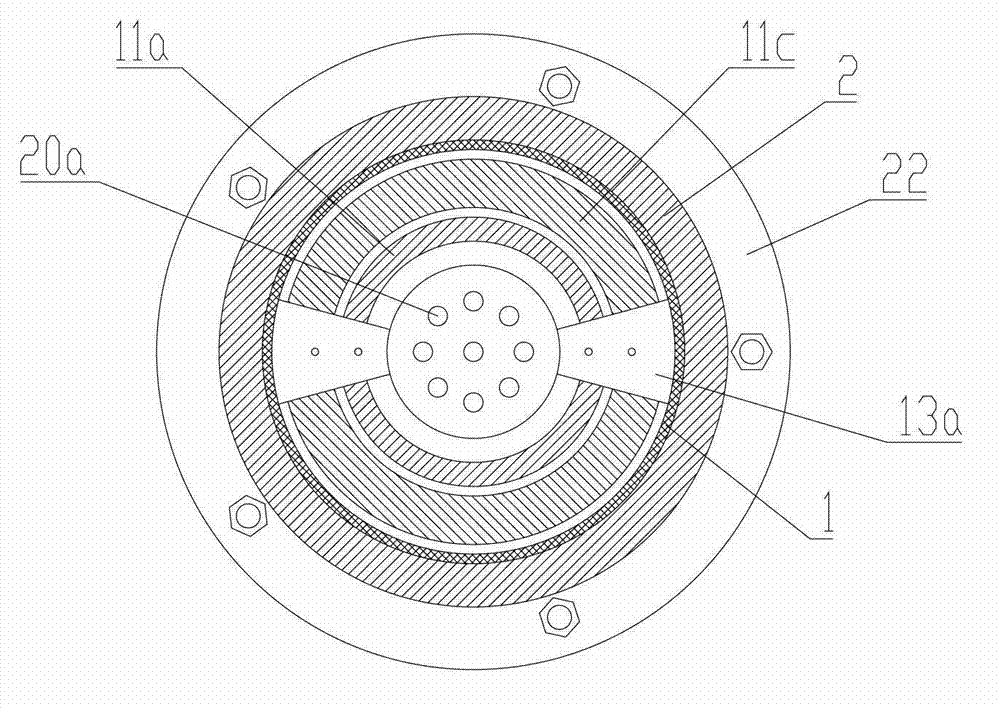

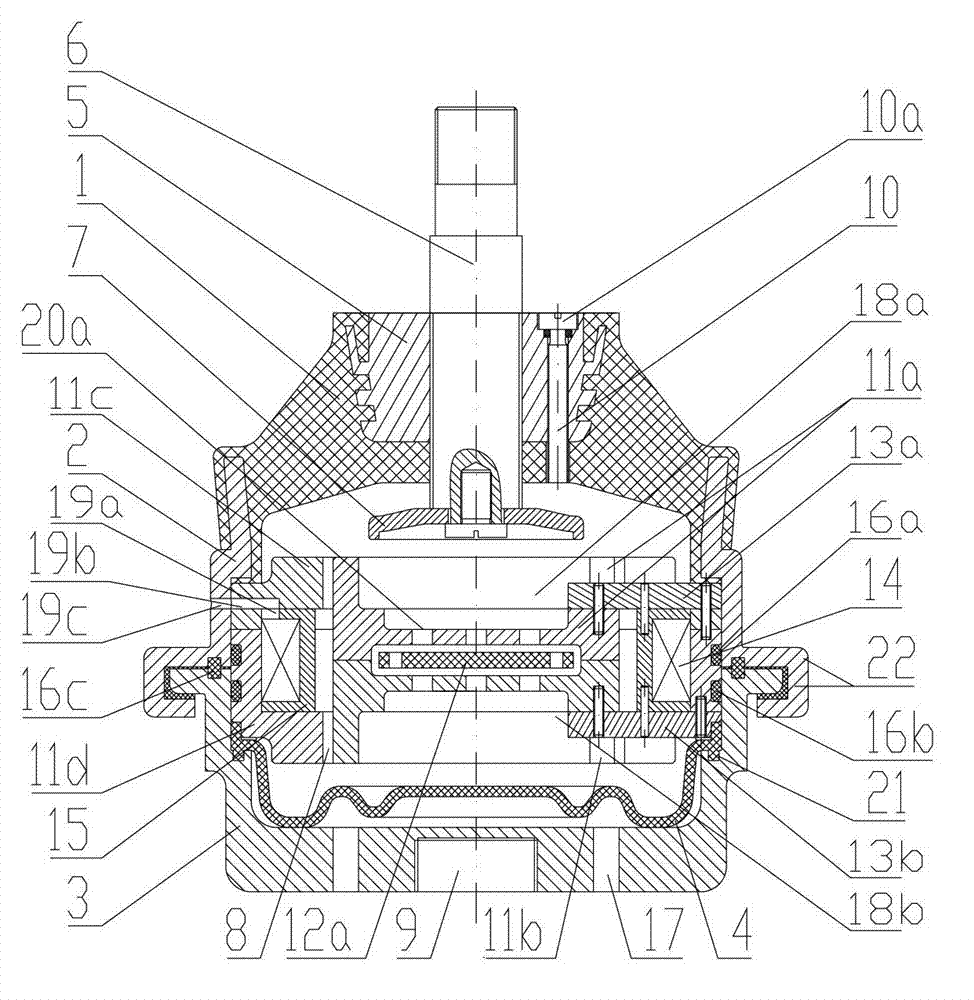

[0029] The present invention will be described in detail below in conjunction with accompanying drawing, as figure 1 with 2 Shown: The magneto-rheological vibration isolator of the automobile engine mount system of the present invention includes a rubber main spring 1, a reinforcement block 5, a shell with an open top and a magnetic core assembly arranged inside the shell, and the shell includes an upper Housing 2 and lower housing 3, the lower end surface of the upper housing 2 and the upper end surface of the lower housing 3 are respectively provided with a circle of flanges 22 protruding outward perpendicular to the axis of the housing, and the bolts are installed in the flanges In the hole on the plate, screw in the nut and compress to realize the fixed connection between the upper shell 2 and the lower shell 3. The rubber main spring 1 is set and blocked at the opening at the top of the housing, and the rubber main spring 1 is concentrically provided with a connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com