Hydraulic bushing comprising metal spacers

A technology of hydraulic bushing and metal spacer, applied in bearings, shock absorbers, mechanical equipment, etc., can solve the problems of leakage, short service life, affecting the use of hydraulic bushings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is introduced below by accompanying drawing.

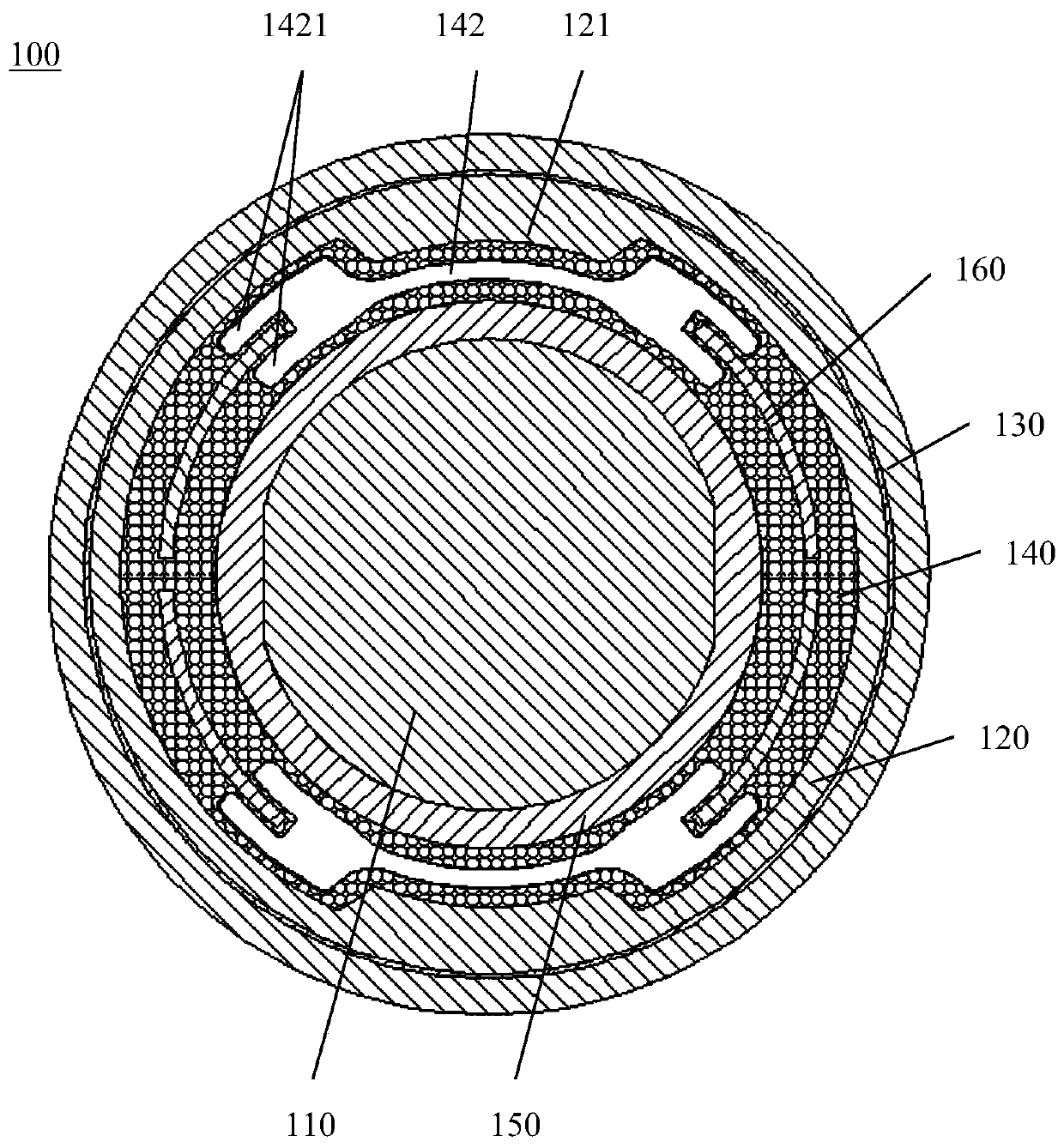

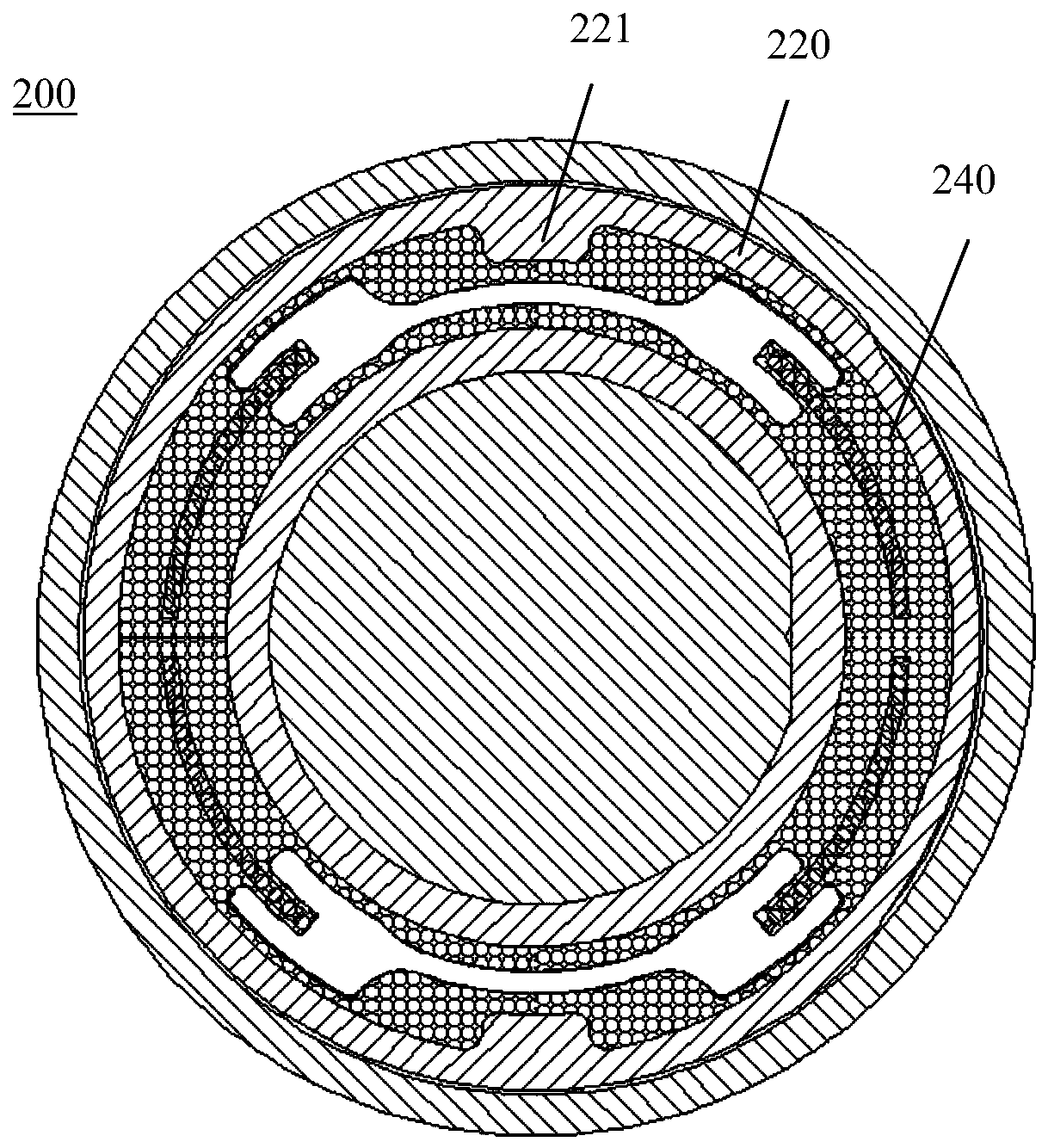

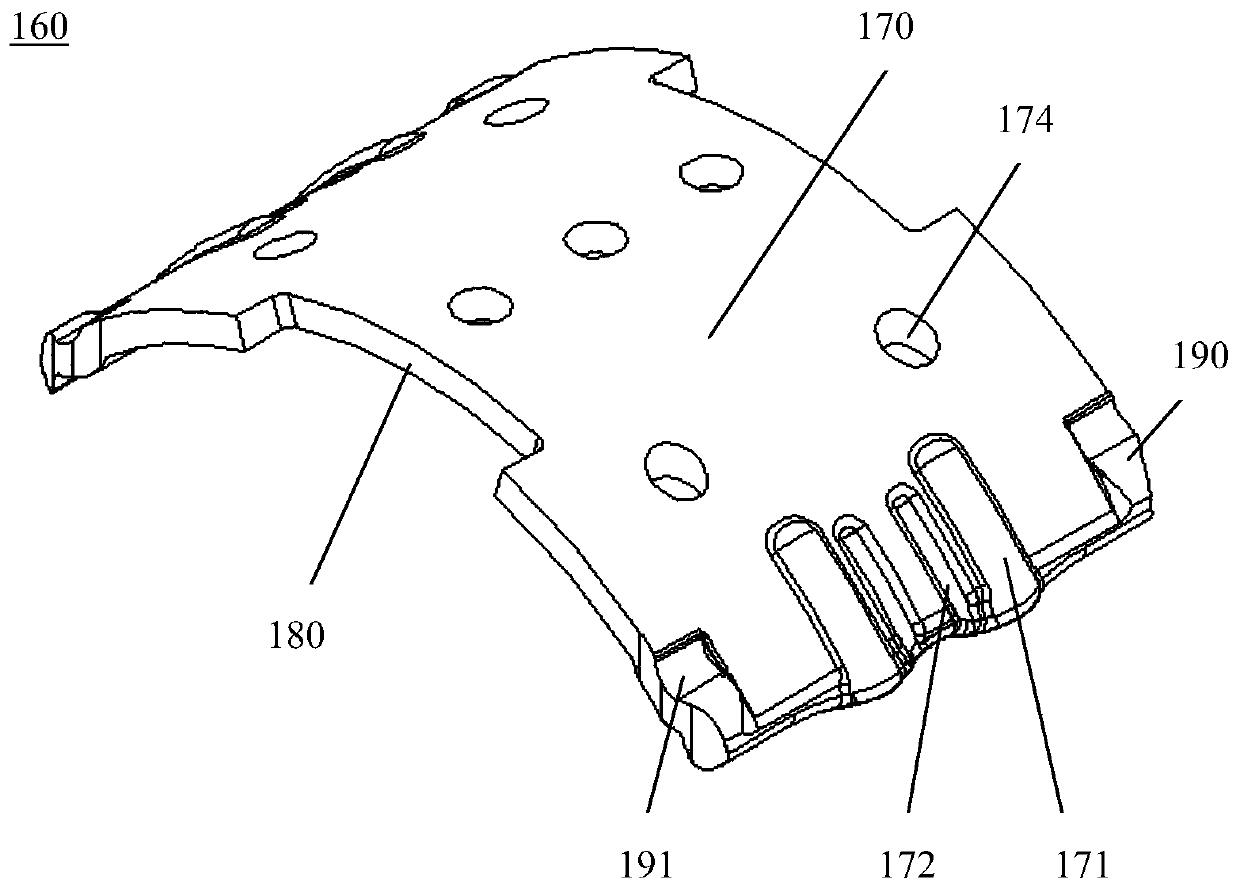

[0029] figure 1 Schematically shows an axial cross-sectional view of a hydraulic bush comprising a metal spacer according to the present invention. Such as figure 1 As shown, the hydraulic bushing 100 includes a mandrel 110 , a flow channel body 120 disposed radially outside the mandrel 110 , and a casing 130 sleeved radially outside the flow channel body 120 in a compression manner. Mandrel 110 is typically a preform. The two ends of the mandrel 110 can be connected with the bogie frame of the railway train, for example, and the outer casing 130 is connected with the positioning boom.

[0030] Such as figure 1 As shown, an inner sleeve 150 is sheathed on the mandrel 110 . A rubber body 140 is filled in the annular gap between the inner sleeve 150 and the flow channel body 120 . Two main liquid cavities 142 for accommodating hydraulic fluid are arranged on the rubber body 140 , and the two main l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com