Polyurethane elastomer material with wide temperature range and high damping capacity and preparation method thereof

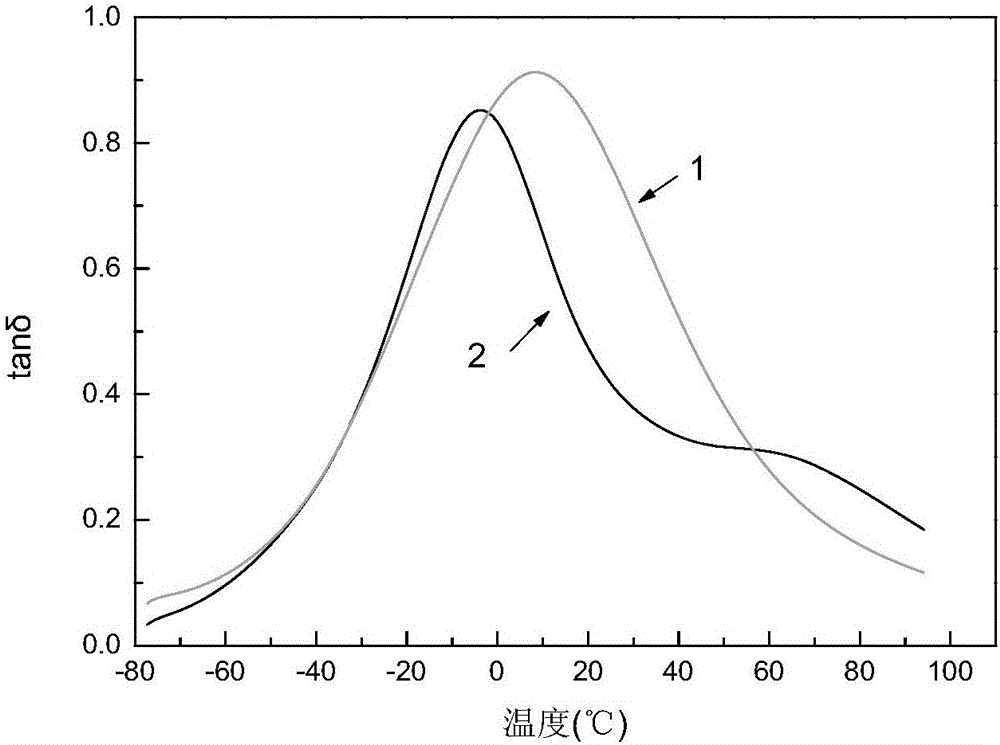

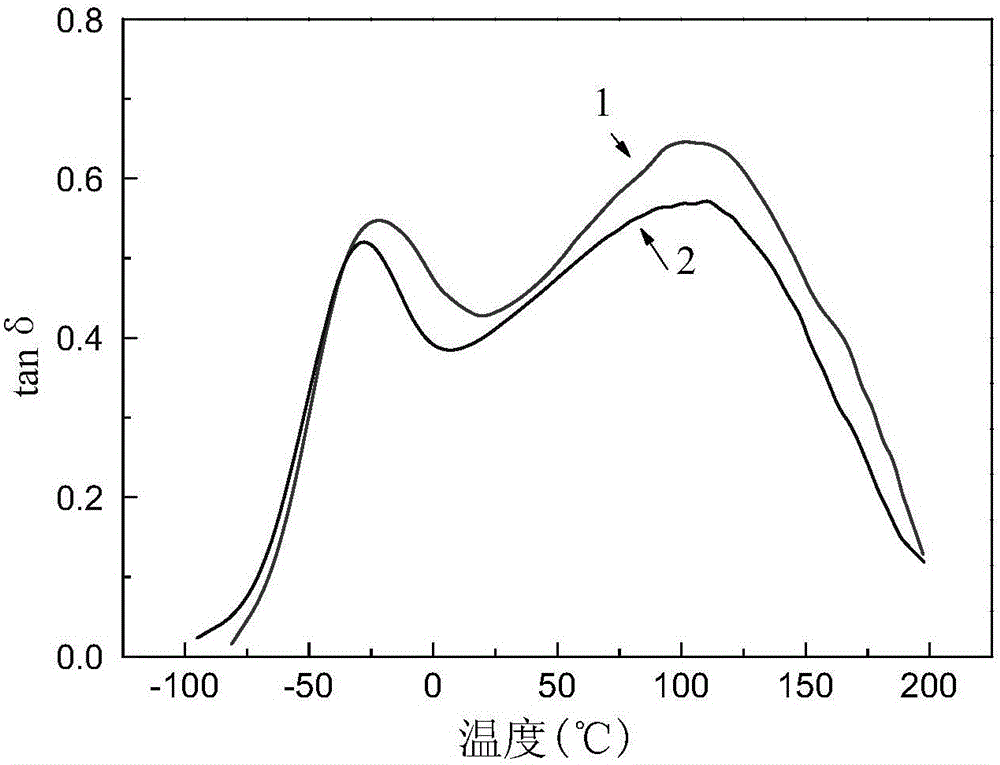

A polyurethane elastomer and wide temperature range technology, applied in the field of polyurethane elastomer, can solve the problems of poor low-temperature damping performance and inability to meet the use requirements in cold seasons, achieve excellent damping performance, broaden the application field, and improve damping performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035](1) Add 40 parts of polyester diol to a three-necked flask equipped with a condensing reflux tube, a stirrer and a thermometer; seal the device, turn on the heating device and raise the temperature to 105°C, stir (250r / min), and turn on the oil type Vacuum with a vacuum pump and dry for 2 hours at a pressure of 1 MPa.

[0036] (2) After the temperature drops to room temperature, turn off the vacuum pump and turn on N 2 , N 2 Add 9 parts of isophorone diisocyanate under protection, stir (300r / min), heat up to 70°C within a few minutes, add 0.3mL of 50ppm catalyst dibutyltin dilaurate dropwise, keep warm for 2 hours, stop the reaction, and you can get Polyurethane prepolymers of polyester diols, N 2 The vibe is preserved.

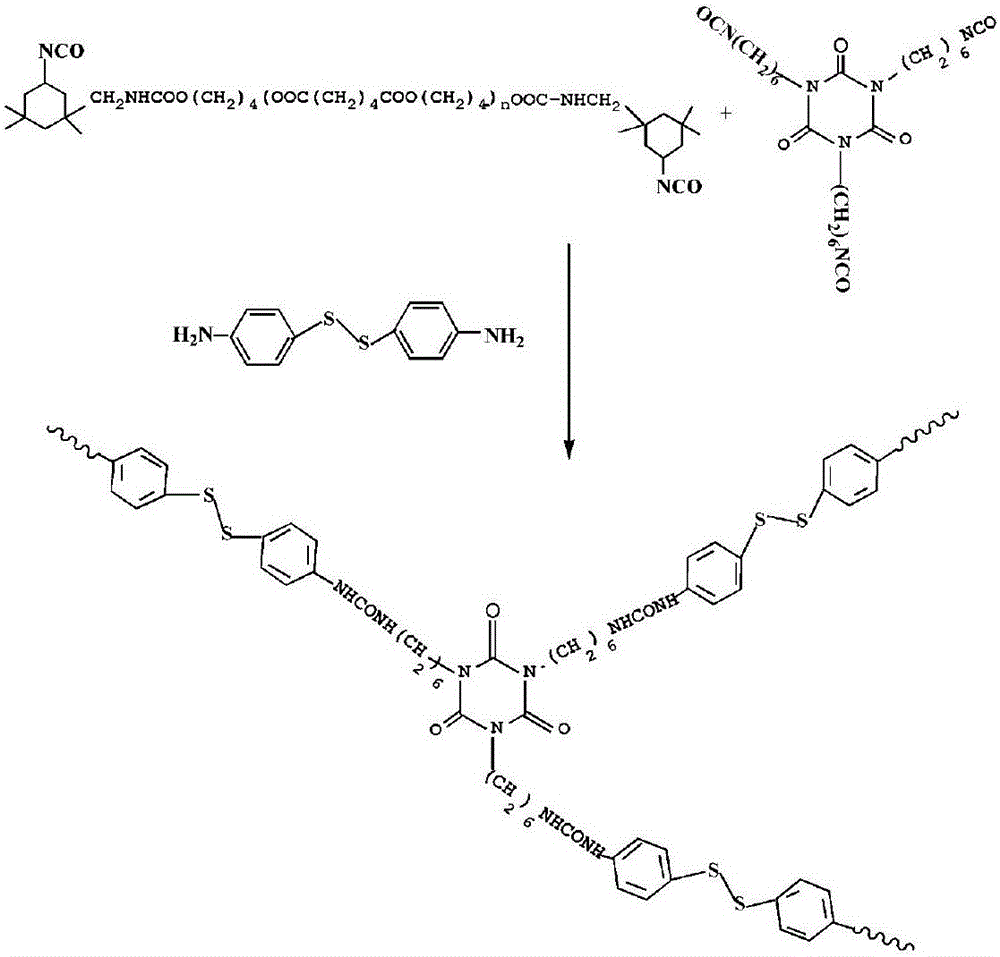

[0037] (3) Take the measured polyurethane prepolymer in a three-necked flask, blow nitrogen, add 14 parts of HDI trimer, and stir (350r / min), the system starts to become transparent and clear.

[0038] (4) Weigh 10 parts of 2,2'‐diaminodiphenyl disu...

Embodiment 2

[0040] (1) Add 40 parts of polyester diol to a three-necked flask equipped with a condensing reflux tube, a stirrer and a thermometer; seal the device, turn on the heating device and raise the temperature to 110°C, stir (200r / min), and turn on the oil type Vacuum the vacuum pump and dry within 1MPa pressure for 2.5h.

[0041] (2) After the temperature drops to room temperature, turn off the vacuum pump and feed N 2 , N 2 Add 9 parts of isophorone diisocyanate under protection, stir (300r / min), heat up to 75°C within a few minutes, add 0.5mL of 50ppm catalyst dibutyltin dilaurate dropwise, keep warm for 3 hours, stop the reaction, and you can Polyurethane prepolymers to obtain polyester diols, N 2 The vibe is preserved.

[0042] (3) Take the measured polyurethane prepolymer in a three-necked flask, blow nitrogen, add 14 parts of HDI trimer, stir (350r / min), and the system starts to become transparent and clear.

[0043] (4) Weigh 10 parts of 3,3'‐dihydroxydiphenyl disulfide...

Embodiment 3

[0045] (1) In a three-necked flask equipped with a condensing reflux tube, a stirrer and a thermometer, add 40 parts of polyester diol; seal the device, turn on the heating device and raise the temperature to 115°C, stir (200r / min), and turn on the oil Vacuum with a vacuum pump and dry for 2.5 hours at a pressure of 1MPa.

[0046] (2) After the temperature drops to room temperature, turn off the vacuum pump and turn on N 2 , N 2 Add 9 parts of isophorone diisocyanate under protection, stir (300r / min), heat up to 70°C within a few minutes, add 0.4mL of 50ppm catalyst dibutyltin dilaurate dropwise, stop the reaction after keeping warm for 3 hours, and you can get Polyurethane prepolymers of polyester diols, N 2 The vibe is preserved.

[0047] (3) Take the measured polyurethane prepolymer in a three-necked flask, pass nitrogen gas, then add 14 parts of HDI trimer, and stir (350r / min), the system starts to become transparent and clear.

[0048] (4) Weigh 10 parts of 4,4'‐diami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com