Organic polymer polyurethane elastomer and preparation method thereof

A technology of polyurethane elastomer and organic polymer, which is applied in the field of organic polymer polyurethane elastomer and its preparation, can solve problems such as falling blocks and degumming, achieve good impact absorption and damping, excellent oil resistance, eliminate noise and The effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

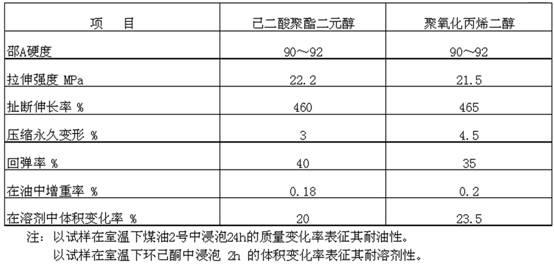

[0022] The preparation method of the organic polymer polyurethane elastomer of the present invention comprises the following steps: 1) adding 40% to 65% of the oligomer polyol into a reaction kettle equipped with a thermometer, a stirrer, a cooling device and a nitrogen inlet, at 110 Dehydration and vacuuming at ~140°C for 1 hour, then cooling down to 65~75°C, adding 20%~38% toluene diisocyanic acid, stirring and reacting at 75±5°C for 1.5~2 hours, then vacuum degassing to obtain isocyanate pre Polymer; Wherein said oligomer polyol is optional in adipic acid polyester diol, polyoxypropylene diol;

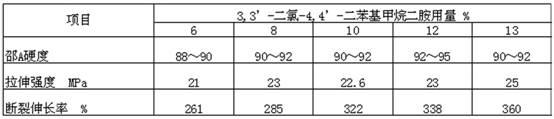

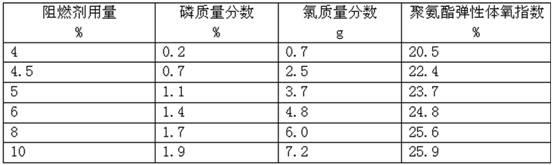

[0023] 2) Add 6% to 13% of 3,3'-dichloro-4,4'-diphenylmethanediamine and 8% to 12% of compounding agent to the isocyanate prepolymer obtained in step 1, mix and stir evenly 1 to 2 minutes, vacuuming for 2 to 3 minutes to obtain a polyurethane polymer material; the compounding agent is a flame retardant or an antistatic agent or a combination of the two; the flame retardant is an add...

Embodiment 1

[0028] In this example, the organic polymer polyurethane elastomer consists of 53% adipic acid polyester diol, 24% toluene diisocyanate, 11% 3,3'-dichloro-4,4'-diphenylmethanediamine, tetra (2-Chloroethyl)-2.2-bis(chloromethyl)-1,3-propylene diphosphate 8%, quaternary ammonium salt cation and nonionic composite surfactant 4%.

[0029] Preparation steps: 1) Add 53% adipic acid polyester diol into a reaction kettle equipped with a thermometer, agitator, cooling device and nitrogen inlet, dehydrate and vacuumize at 110°C for 1 hour, then cool down to 65°C , adding 24% toluene diisocyanic acid and stirring at 75±5°C for 1.5h, then vacuum defoaming to obtain isocyanate prepolymer;

[0030] 2) Add 11% of 3,3'-dichloro-4,4'-diphenylmethanediamine and 8% of tetrakis(2-chloroethyl)-2.2-bis to the isocyanate prepolymer obtained in step 1 (Chloromethyl)-1,3-propylene diphosphate, 4% quaternary ammonium salt cationic and nonionic composite surfactant, mixed and stirred evenly for 1.5 min...

Embodiment 2

[0034] In this example, the organic polymer polyurethane elastomer is composed of 60% of adipic acid polyester diol, 26% of toluene diisocyanate, 6% of 3,3'-dichloro-4,4'-diphenylmethanediamine, 6% of tetra (2-Chloroethyl)-2.2-bis(chloromethyl)-1,3-propylene diphosphate 8%.

[0035] Preparation steps: 1) Add 60% adipic acid polyester diol into a reaction kettle equipped with a thermometer, agitator, cooling device and nitrogen inlet, dehydrate and vacuumize at 130°C for 1 hour, then cool down to 70°C , adding 26% of toluene diisocyanic acid, stirring and reacting at 75±5°C for 2 hours, and then vacuum degassing to obtain isocyanate prepolymer;

[0036]2) Add 6% of 3,3'-dichloro-4,4'-diphenylmethanediamine and 8% of tetrakis(2-chloroethyl)-2.2-diamine to the isocyanate prepolymer obtained in step 1 (Chloromethyl)-1,3-propylene diphosphate, mix and stir evenly for 1 minute, and vacuumize for 2 minutes to obtain polyurethane polymer materials;

[0037] 3) Pour the polyurethane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com