Preparation method of thin film transistor of liquid crystal display panel and liquid crystal display panel

A technology for liquid crystal display panels and thin film transistors, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, optics, etc., can solve problems such as electrostatic breakdown and burning of TFT film layers, and achieve the effect of not easy electrostatic breakdown.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

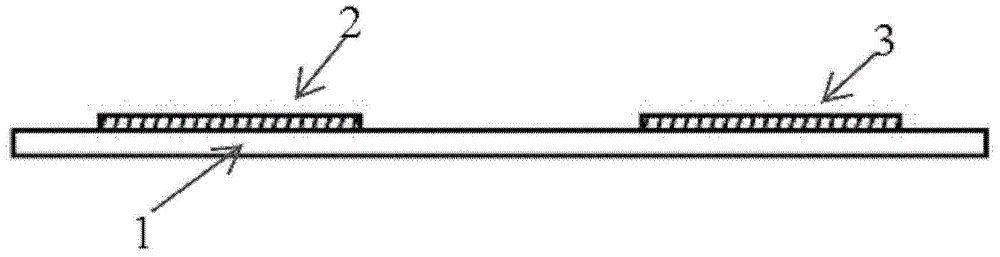

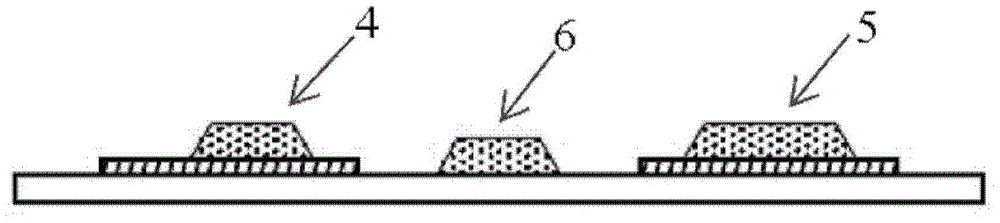

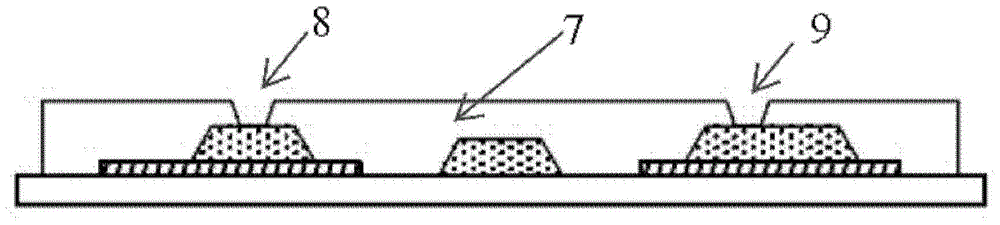

[0063] Referring to FIG. 2 , it shows a schematic diagram of a method for manufacturing a thin film transistor for a liquid crystal display panel according to a first embodiment of the present invention. Figure 2a-2e A schematic cross-sectional view of a thin film transistor obtained through multiple steps in the first embodiment is shown. Here, as mentioned above, the connection of the base electrodes of two adjacent pixels is also used as an example for the corresponding description, and only the corresponding structural arrangement is shown in the accompanying drawings.

[0064] see Figure 2a , a first ITO layer having a predetermined pattern is formed on the substrate 21 for a liquid crystal display panel in the same manner as in the prior art. As shown in the figure, two spaced-apart regions 22 , 23 of the first ITO layer are formed on the illustrated substrate 21 . It should be noted that a plurality of spaced-apart regions can be formed on the substrate 21 to form a ...

no. 2 example

[0072] Referring to FIG. 3 , it shows a schematic diagram of a method for manufacturing a thin film transistor for a liquid crystal display panel according to a second embodiment of the present invention. Figures 3a-3g A schematic cross-sectional view of a thin film transistor obtained through multiple steps in the second embodiment is shown.

[0073] see Figure 3a , a first ITO layer having a predetermined pattern is formed on the substrate 41 of the liquid crystal display panel in the same manner as in the prior art. As shown, two spaced-apart regions 42 , 43 of the first ITO layer are formed on the illustrated substrate 41 . It should be noted that a plurality of spaced-apart regions may be formed on the substrate 41 , and here only two spaced-apart regions are shown for the purpose of illustration and description. A gate metal layer is deposited, and the mask of the gate is changed to increase the connection line portion between the metal island and the gate wire. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com