Efficient and low-noise multi-layer flow collector and centrifugal fan

A collector, low-noise technology, used in machines/engines, mechanical equipment, liquid fuel engines, etc., can solve problems such as inability to control small unit gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

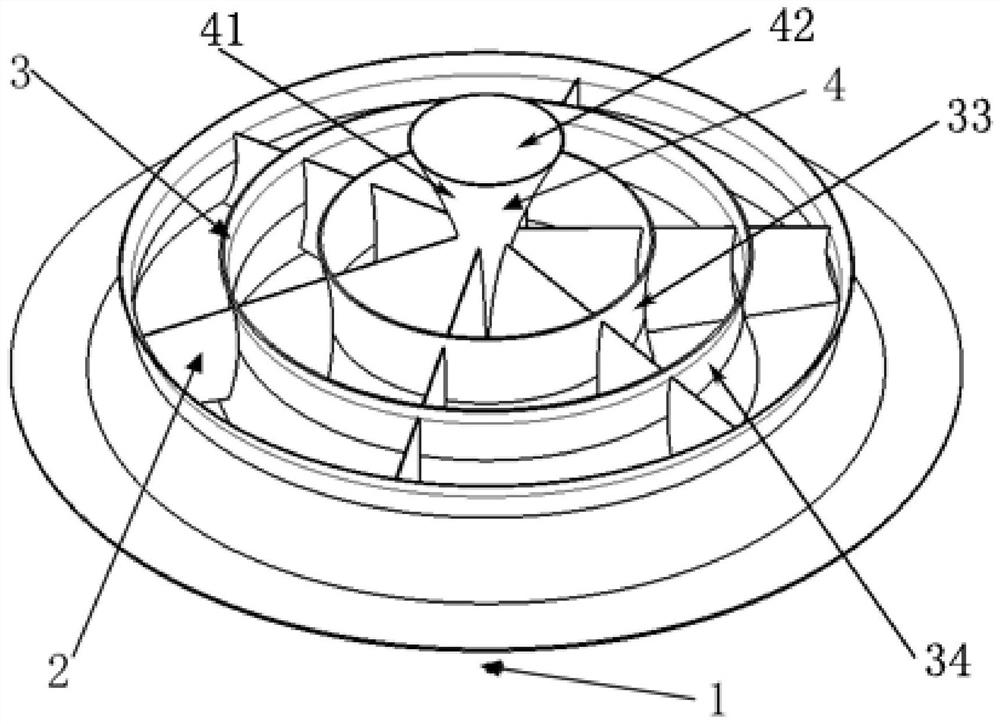

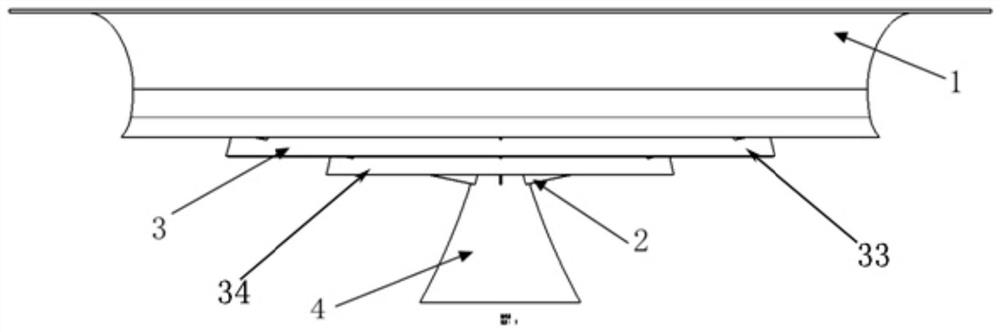

[0067] Such as image 3 and 4 As shown, this embodiment only describes the difference from the above embodiment, and the rest of the technical features are the same as the above embodiment. The current collector also includes a guide cone 4, which is arranged in the inner ring of the collector tube 3 adjacent to the center of the collector body 1, and the guide cone 4 is connected to the cascade. 2 connections. The header 3 is axially inserted into the impeller and the guide cone 4 is designed to better guide the gas into the impeller. The purpose of this design is to optimize the flow field at the impeller inlet, improve the efficiency of the fan, and reduce the noise of the fan. The material of the collector body 1 , collector barrel 3 , cascade 2 and diversion cone 4 is plastic or metal.

[0068] Preferably, along the flow direction of the gas, the side 41 adjacent to the apex of the guide cone 4 is connected to one end of the cascade 2 , and the bottom surface 42 of the...

Embodiment 3

[0070] This embodiment only describes the difference from the above embodiment, and other technical features are the same as the above embodiment. In this embodiment, the inner diameter of the outlet section 12 increases gradually from the gas inlet to the outlet.

Embodiment 4

[0072] This embodiment only describes the difference from the above embodiment, and other technical features are the same as the above embodiment. In this embodiment, the outlet section 12 is multi-arc, and its axial cross-section along the direction from the gas inlet to the outlet includes a plurality of arc segments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com