Water sensing devices and methods utilizing same to control flow of subsurface fluids

A technology for controlling fluids and fluids, which can be used in the fields of production of fluids, valve devices of wellbore/well, earth-moving drilling, etc., which can solve the problems of reducing the quantity and quality of oil produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

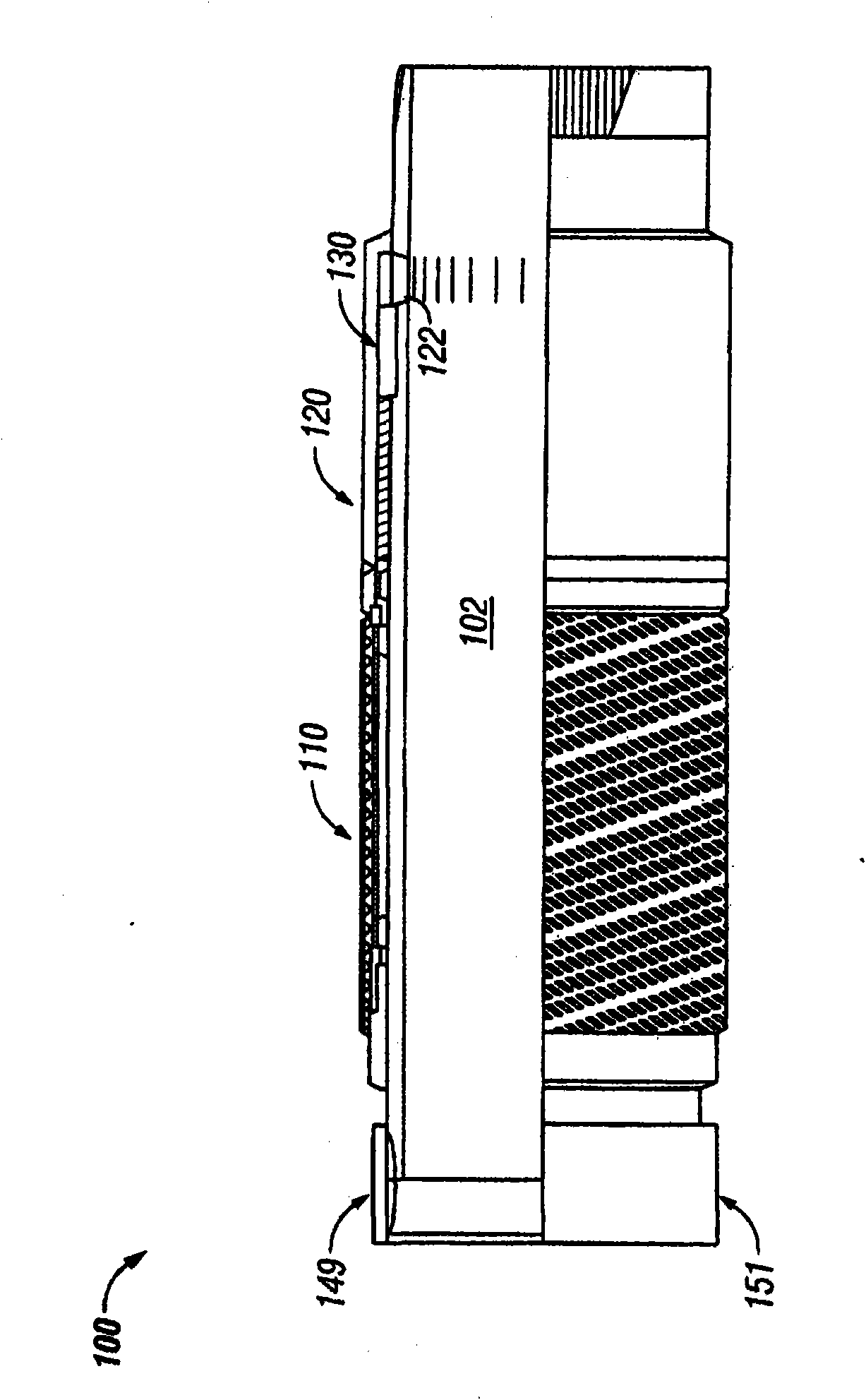

[0017] The present invention relates to apparatus and methods for controlling the production of hydrocarbon production wells. The present invention allows various forms of embodiment. What has been shown in the drawings and described in detail herein is a specific embodiment of the invention. It is to be understood that the invention is to be considered as an example of the principles of the invention and not to limit the invention to what has been shown and described herein. Further, although an embodiment has been described as having one or more features or a combination of two or more features, such feature or feature combination should not be considered essential unless expressly stated otherwise.

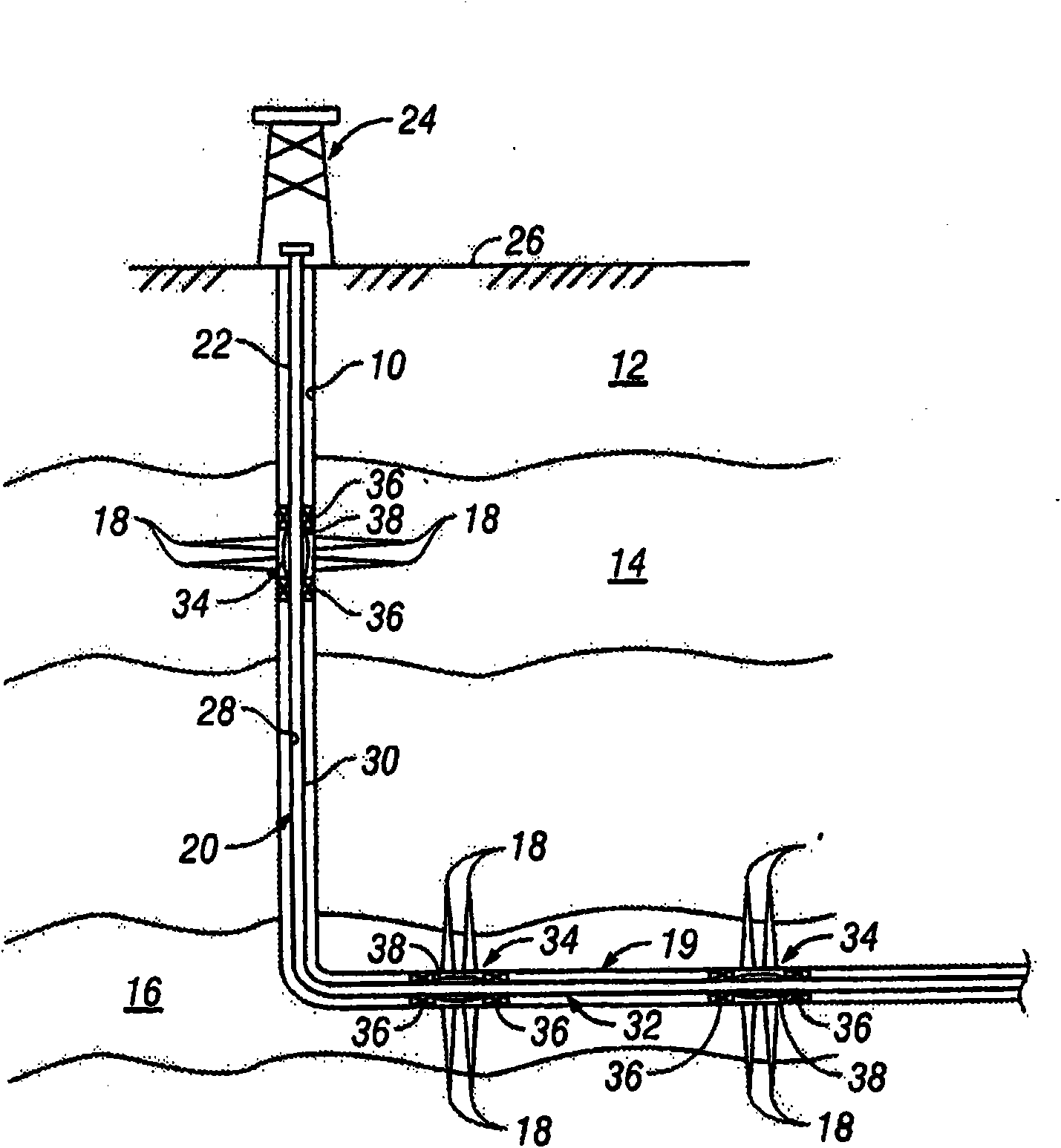

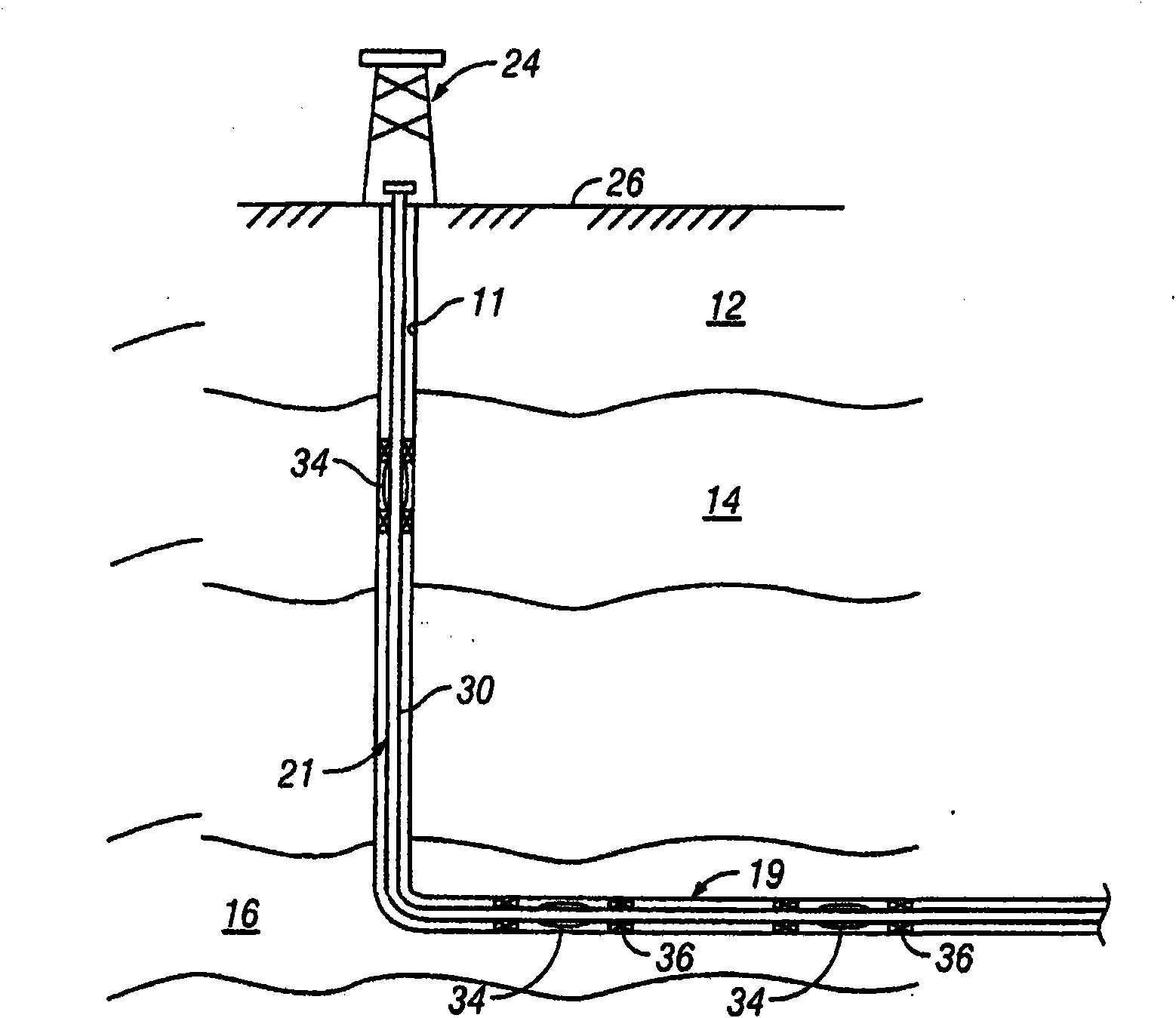

[0018] see first figure 1 , shows an exemplary wellbore 10 drilled through a formation 12 into a pair of formations 14, 16 from which hydrocarbons are expected to be produced. A metal casing is inserted in the wellbore 10, as is well known in the art, and a number of perforat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com