Auxiliary runner structure for preventing deformation of injection product

A technology of injection molding products and auxiliary flow, applied in the field of injection molding process equipment, can solve problems such as affecting the assembly of assembly parts, easy to be damaged, and easy to be distorted and deformed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]The present invention will be described in detail below with reference to the accompanying drawings and specific examples, which are not particularly defined by the present invention.

[0025]Some of the existing products, the appearance requires high, during the injection molding process, the product is not ideal in the capacity of the mobile terminal, that is, the pressure can not make the plastic to the flow end for suppression. How to solve the contraction deformation of the product in the disconnection, becoming the key to such parts in the injection molding process.

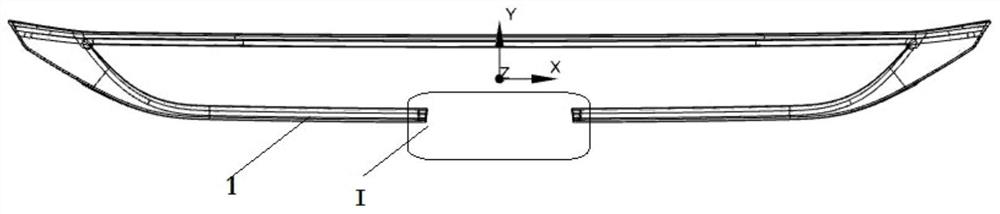

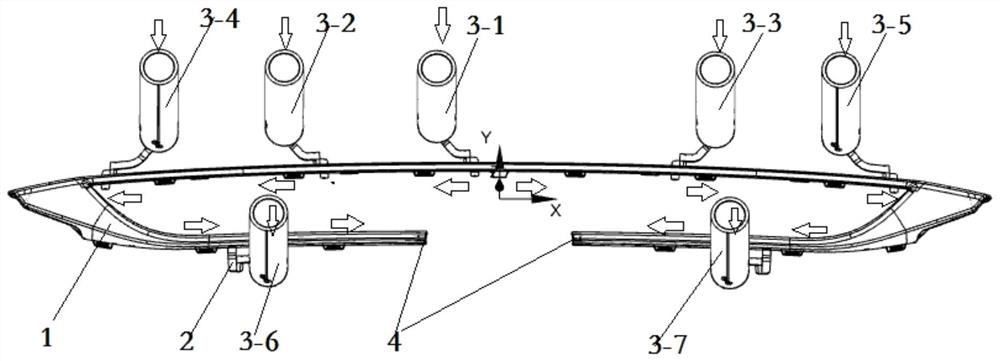

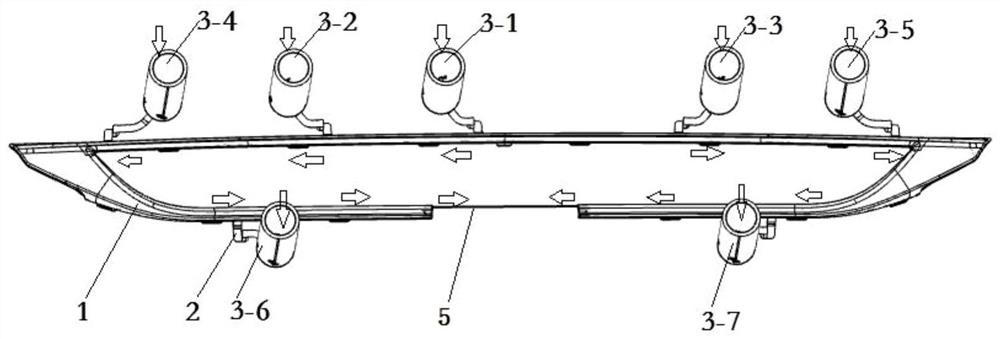

[0026]Such asfigure 1 The products shown in the prior art, the outer surface is the outer surface, the following is a non-external surface, after injection molding, I need to perform electroplating, I is disconnected, the flow end of the product is injection molded, disconnected There are three directions in X, Y, Z. Since the appearance quality requirements are very high, there is no appearance of the appearance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com