Electroluminescence automatic imaging apparatus

An imaging device and electroluminescence technology, which are used in electrical excitation analysis, material excitation analysis, optical testing flaws/defects, etc., can solve the problems of uncertain judgment, visual fatigue, difficulty in rework, etc. The effect of reducing visual fatigue and fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

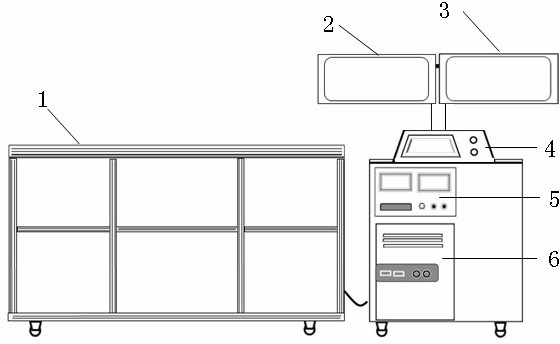

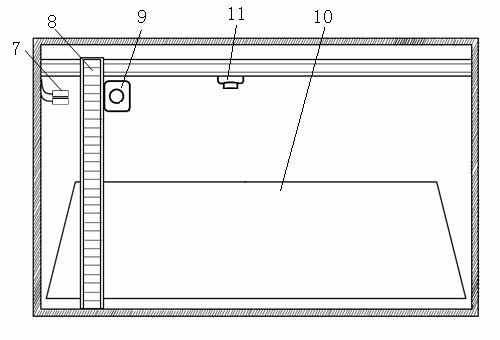

[0020] see figure 1 and figure 2 , figure 1 It is a schematic diagram of the front structure of the electroluminescent automatic imaging device of the present invention. figure 2 It is a schematic diagram of the internal structure of the electroluminescent automatic imaging device of the present invention. Depend on figure 1 and figure 2 It can be seen that the electroluminescent automatic imaging device of the present invention includes a measurement platform 1, a display I2, a display II3, a control platform 4, a current source 5, a computer 6, a current connector 7, an XY high-speed positioning system 8, a camera I9, and a mirror 10 and Camera II11.

[0021] The control platform 4 is connected with the measurement platform 1 by an optical fiber / data line, and the control platform 4 is an operating device for issuing instructions. The control platform 4 is provided with a current source 5 and a computer 6, and the control platform 4 is provided with a display I2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com