Dynamic experimental device and method for evaluating performance of scale inhibitor on oil field

A technology for evaluating devices and scale inhibitors, which is applied in measurement devices, analysis of suspensions and porous materials, instruments, etc., can solve the problems of poor use effect, large amount of scaling, cumbersome steps, etc., and achieve a high degree of automation and control , Easy to maintain and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

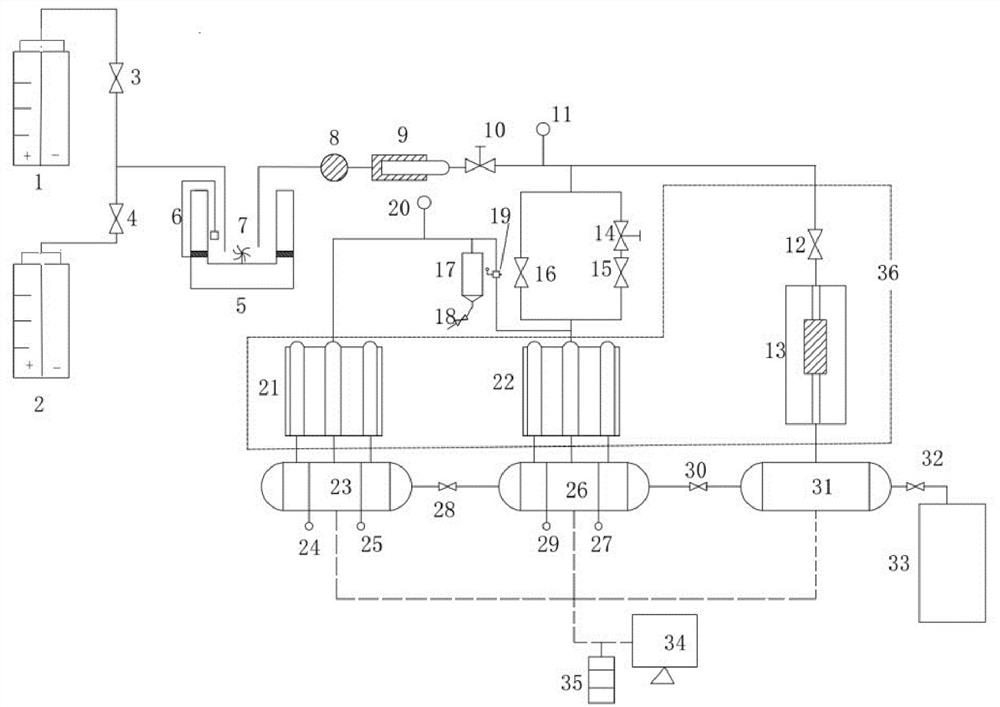

[0036] refer to figure 1, an oilfield dynamic scaling and anti-scaling evaluation device, comprising;

[0037] The simulated formation water raw solution tank 1, the left side of the simulated formation water raw solution tank 1 is the cation water tank, the right side is the anion water tank, connected with the simulated injection water raw solution tank 2 through the first control valve 3 and the second control valve 4, and the simulated injection water raw solution tank 2 On the left is the cation water tank and on the right is the anion water tank;

[0038] Mixing tank 5, on which there is a thermal sensor and a heating ring 6 to control the mixed liquid system to reach a preset temperature, and the bottom spiral agitator 7 can fully mix the liquid to avoid crystallization, and is connected with the simulated formation water raw liquid tank 1 and simulated Injected water stock solution tank 2 is connected;

[0039] The terminal signal acquisition device 35, the terminal ...

Embodiment 2

[0044] refer to figure 1 , further, the core displacement dynamic experiment device 13, the core displacement dynamic experiment device 13 is connected to the liquid outlet end of the mixed liquid tank 5 and the high-pressure injection pump 9 through the liquid inlet line, and the other end is connected to the single-layer reaction liquid collection tank , to perform core dynamic displacement evaluation, and the entire rock core dynamic displacement evaluation device is placed in the constant temperature box 36 .

[0045] In the above embodiment, after the core dynamic displacement experiment device 13 passes the displacement experiment, the reaction liquid enters the single-layer reaction liquid collection tank 31, and after the conductivity analysis, the data is transmitted to the terminal signal acquisition device 35 and finally recorded in the computer 34 superior.

Embodiment 3

[0047] In combination with the above-mentioned embodiments, the method for dynamic scaling and anti-scaling in oilfields is described in detail:

[0048] In the above-mentioned embodiment, a kind of oilfield dynamic scaling and anti-scaling device is mainly based on the scaling evaluation of parallel pipelines. When the simulated fluid is in a laminar flow state, the experimental procedure is to open the fifth control valve 16, close the third control valve 12, Four control valves 15, put the configured formation water and anion and cation water of injection water into the anion and cation tanks of the simulated formation water stock solution tank 1 and the simulated injection water stock solution tank 2 respectively, and open the first control valve 3 and the second control valve. The valve 4 is injected into the mixed liquid tank 5 according to the ratio of the experimental design. After the thermal sensor, the heating ring 6 and the thermostat 36 are preheated to the simulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com