Building pillar clamping and supporting device

A technology for supporting devices and pillars, which is used in construction, building maintenance, building construction, etc., can solve the problem of inability to give downward force to building pillars, and achieve the effect of stable connection with the ground and preventing overturning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

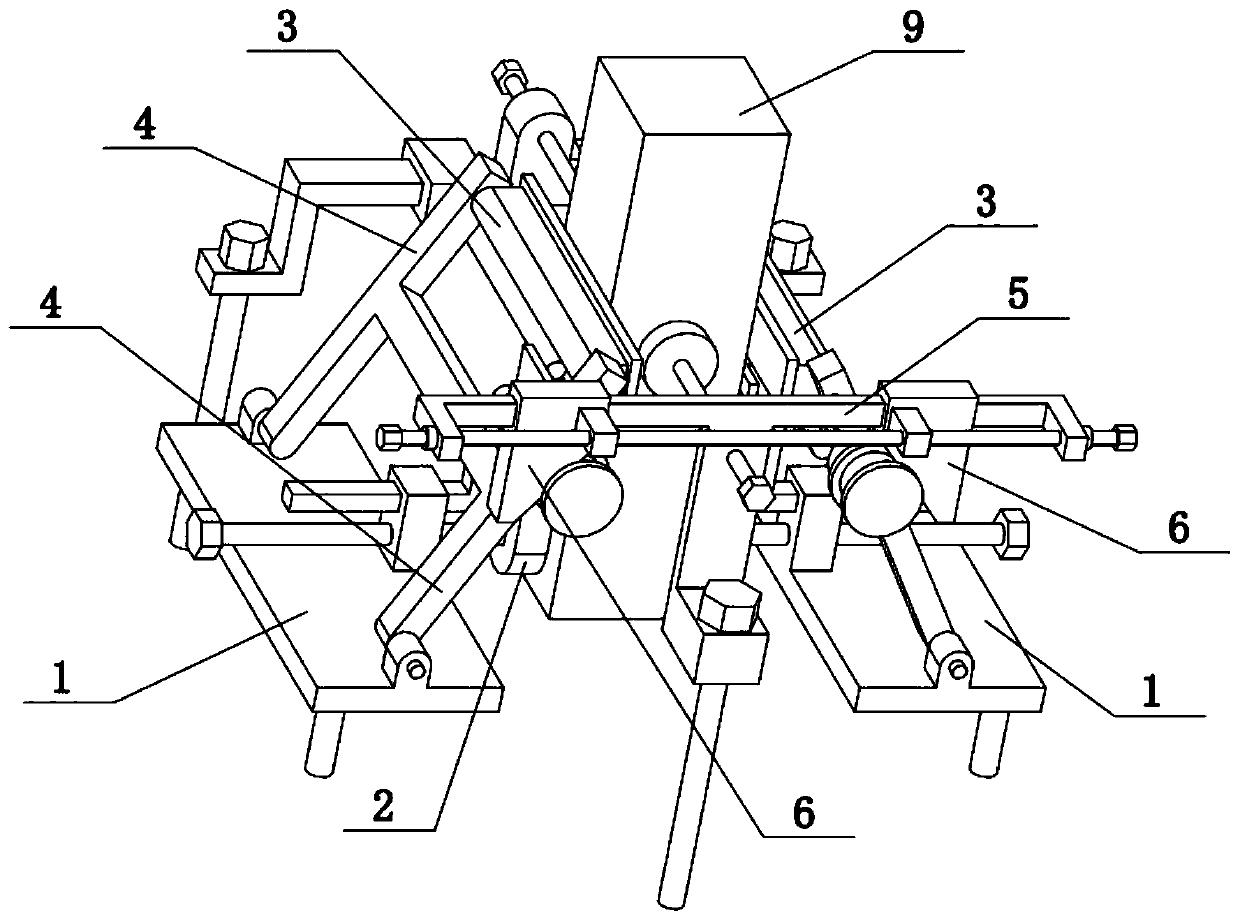

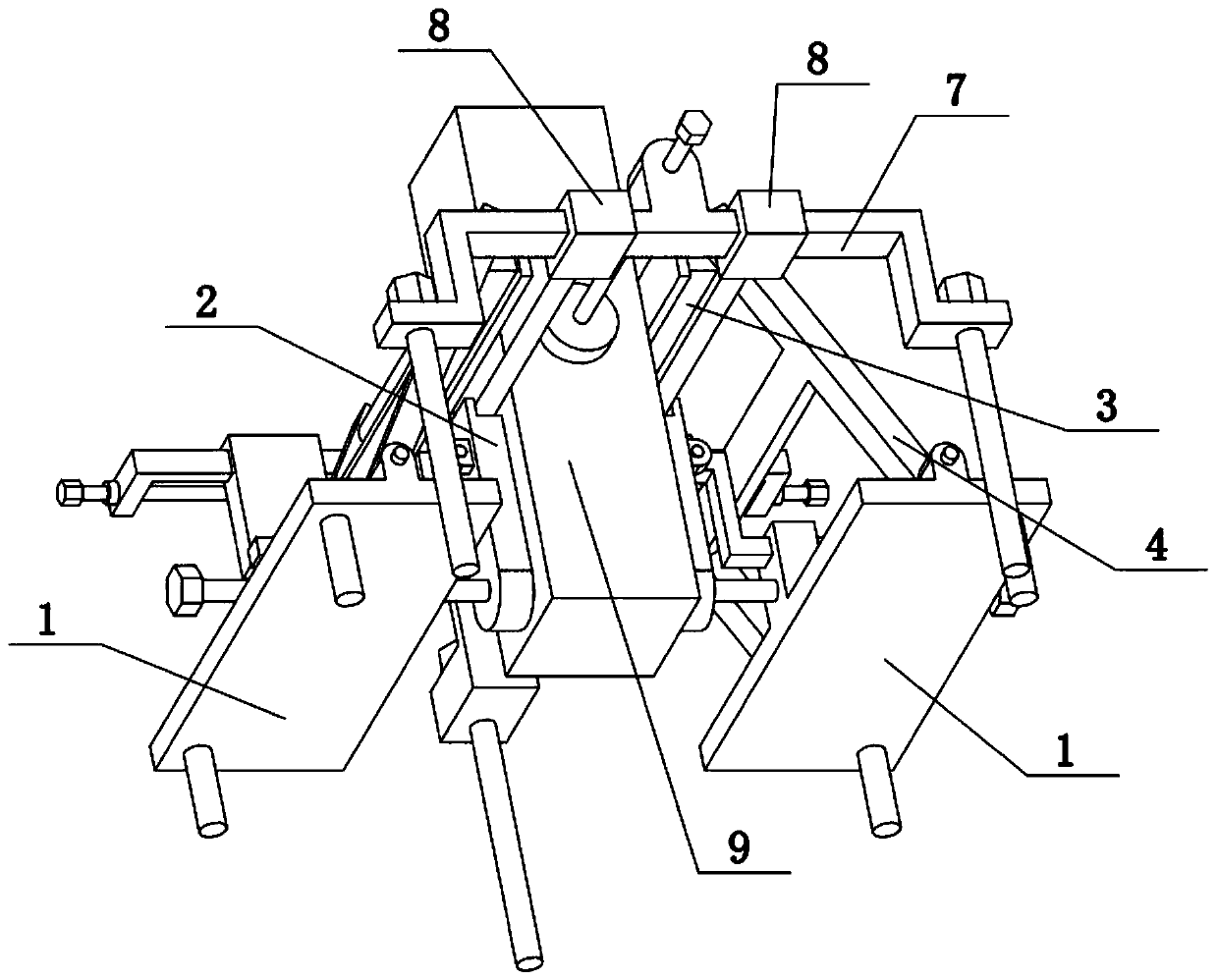

[0032] Combine below Figure 1-8 Describe this embodiment, the present invention relates to the field of construction, more specifically, a clamping and supporting device for building pillars, including a base plate 1, a fixing block 102, a thumb screw 104, a long top bar 2, a horizontal sliding post 202, a folded post 203, slide rail rod II7, ground screw II701, sliding sleeve 8 and lower pressure column 801, the present invention can clamp and support the building pillar 9 to prevent the building pillar 9 from toppling over, and the present invention can give the building pillar 9 downward force, so that the building pillars 9 are more firmly connected to the ground.

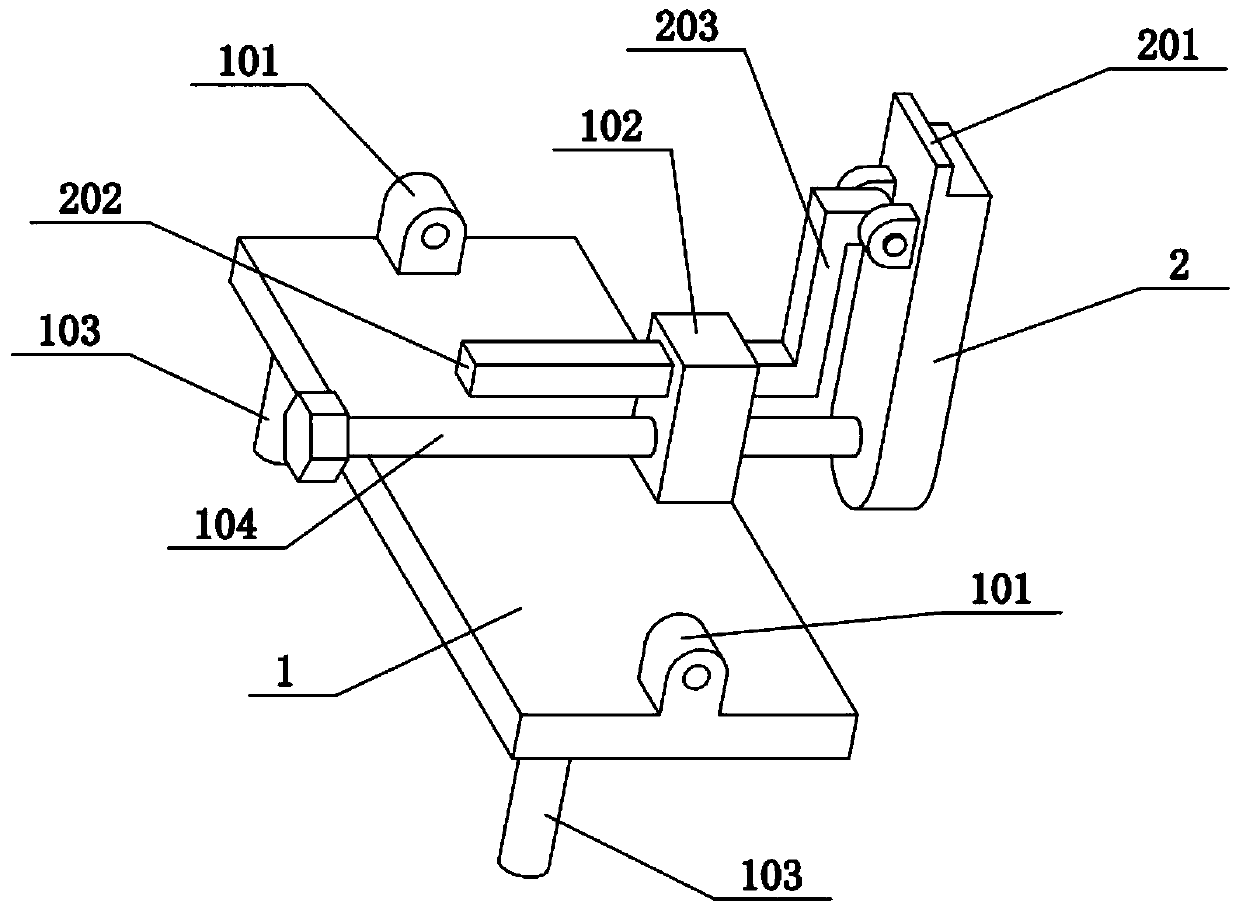

[0033]The bottom plate 1 is provided with two left and right sides, the upper ends of the two bottom plates 1 are fixedly connected with a fixed block 102, and the two fixed blocks 102 are slidably connected with a horizontal sliding column 202, and the inner ends of the two horizontal sliding columns 202 are ...

specific Embodiment approach 2

[0035] Combine below Figure 1-8 To illustrate this embodiment, the clamping and supporting device for building pillars also includes convex ribs 201, the upper ends of the two long top bars 2 are fixedly connected to the convex ribs 201, and the two pressing columns 801 are located on the two convex ribs 201. between. The function of the two convex retaining ribs 201 is to respectively limit the two pressing columns 801 and prevent the two pressing columns 801 from breaking away from the upper sides of the two long top bars 2 .

specific Embodiment approach 3

[0037] Combine below Figure 1-8 To illustrate this embodiment, the clamping and supporting device for building pillars further includes ground nails 103 , and a plurality of ground nails 103 are fixedly connected to the lower sides of the two bottom plates 1 . A plurality of ground nails 103 can be inserted into the ground, so that the two bottom plates 1 are fixed on the ground.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com