MOCVD (Metal-organic Chemical Vapor Deposition) equipment and adjustment method for interval between tray and spray header of equipment

A technology of sprinkler head and equipment, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of complex and complicated equipment structure, reduce pollution, adjust the gap between tray and sprinkler head The spacing of the easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

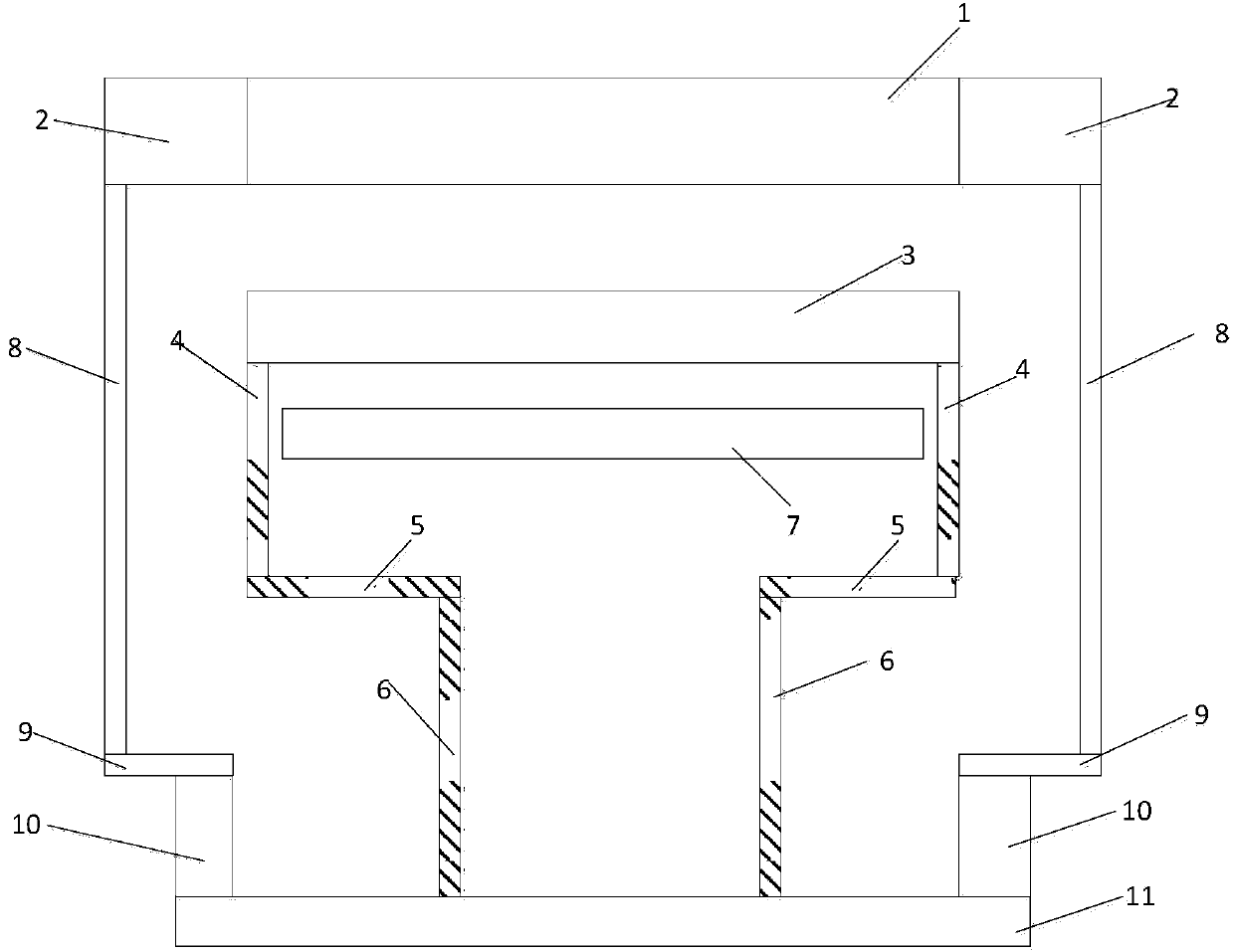

[0037] In the MOCVD equipment of the prior art, the adjustment of the distance between the shower head and the tray is realized by the height of the entire tray in the reaction chamber, and the height of the tray in the reaction chamber is set by the The bellows under the reaction chamber is realized, and there are some transmission parts between the bellows and the tray (for details, please refer to figure 1 and background technology section), the purpose is to enable the tray to rotate. This makes the structure of the entire MOCVD equipment relatively complex, and adjusting the height of the tray in the reaction chamber also involves many related transmission components.

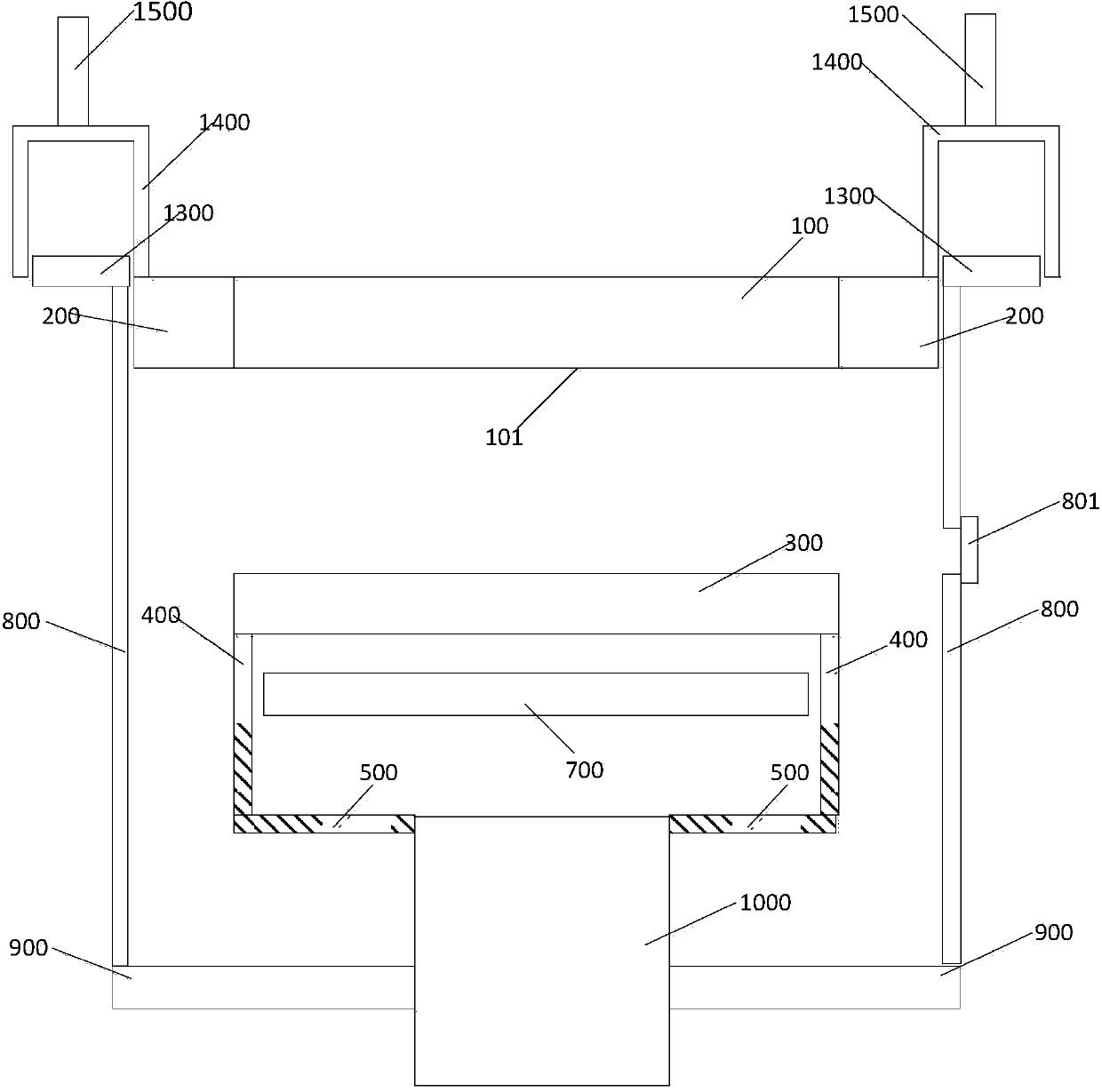

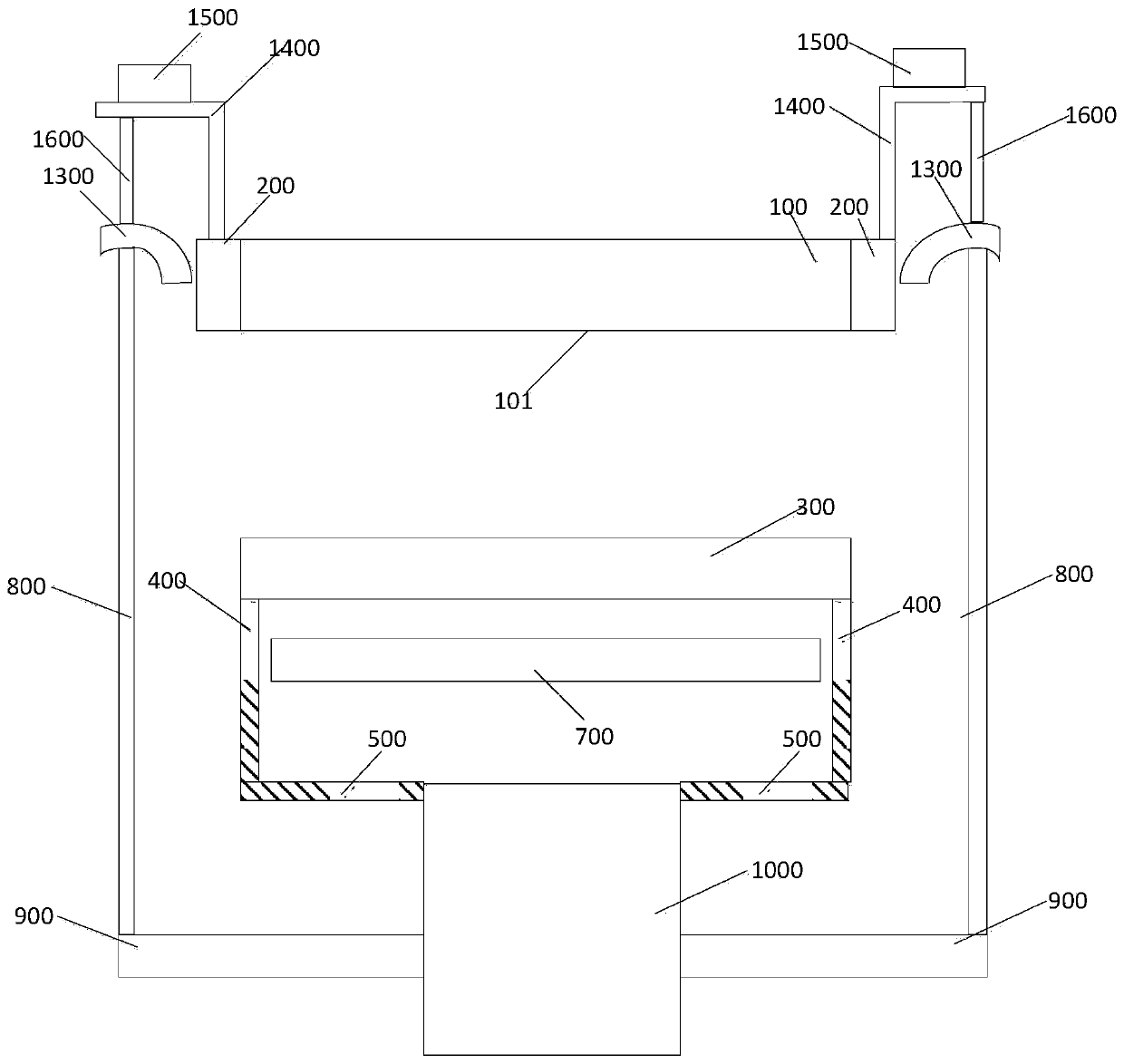

[0038] In order to solve the above problems, the inventors of the present invention considered adjusting the height of the shower head in the reaction chamber, adjusting the distance between the shower head and the tray, and the shower head lifting device connected to the shower head , adjust the height o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com