Device for treating residual rubber of bicycle hub

A technology for processing devices and bicycles, which is applied to grinding drive devices, manufacturing tools, and parts of grinding machine tools, etc., can solve the problems of low efficiency, difficult fixing of wheel hubs, and inconvenient grinding, so as to expand the scope of application and improve efficiency. And grinding quality, convenient grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

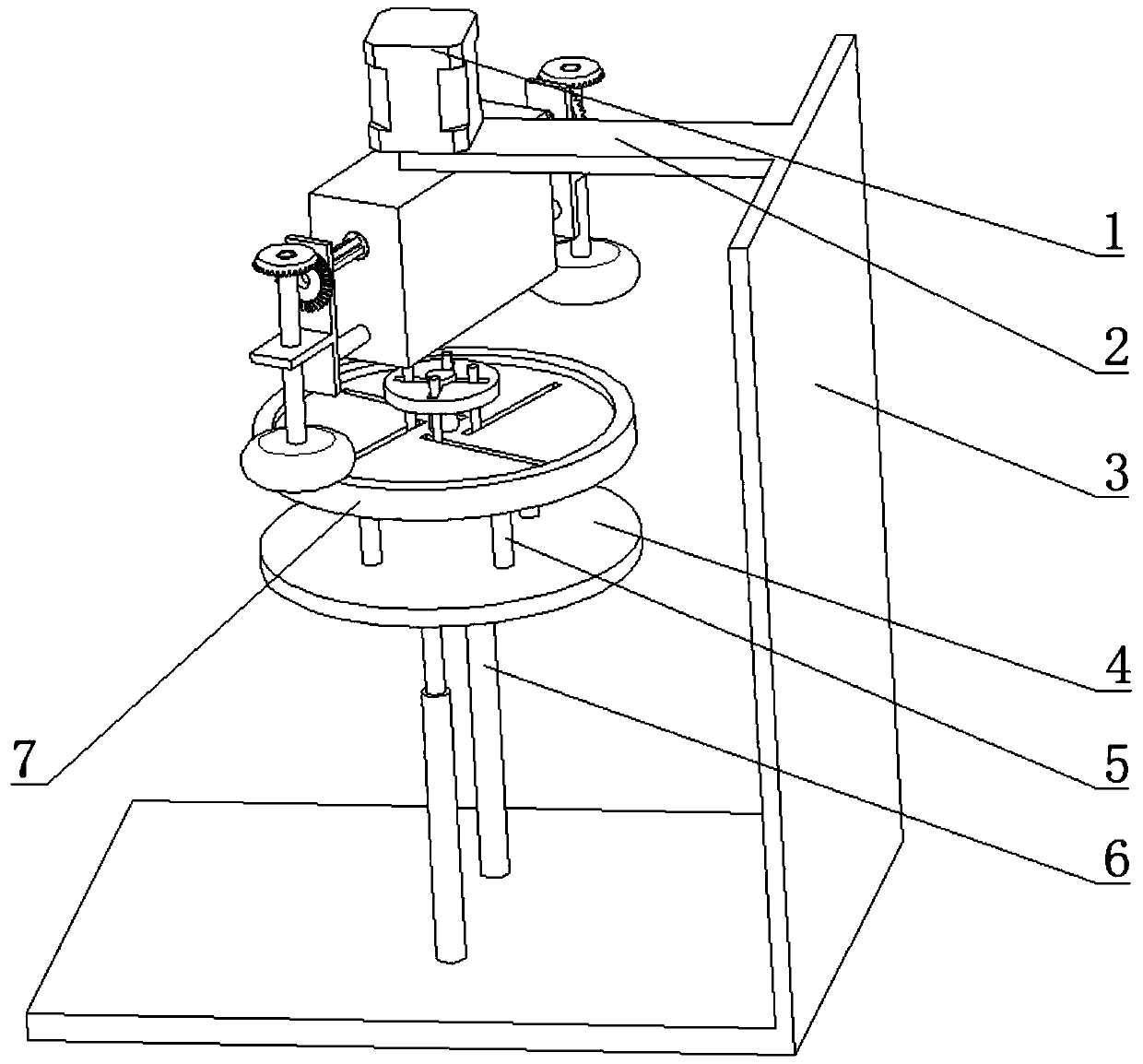

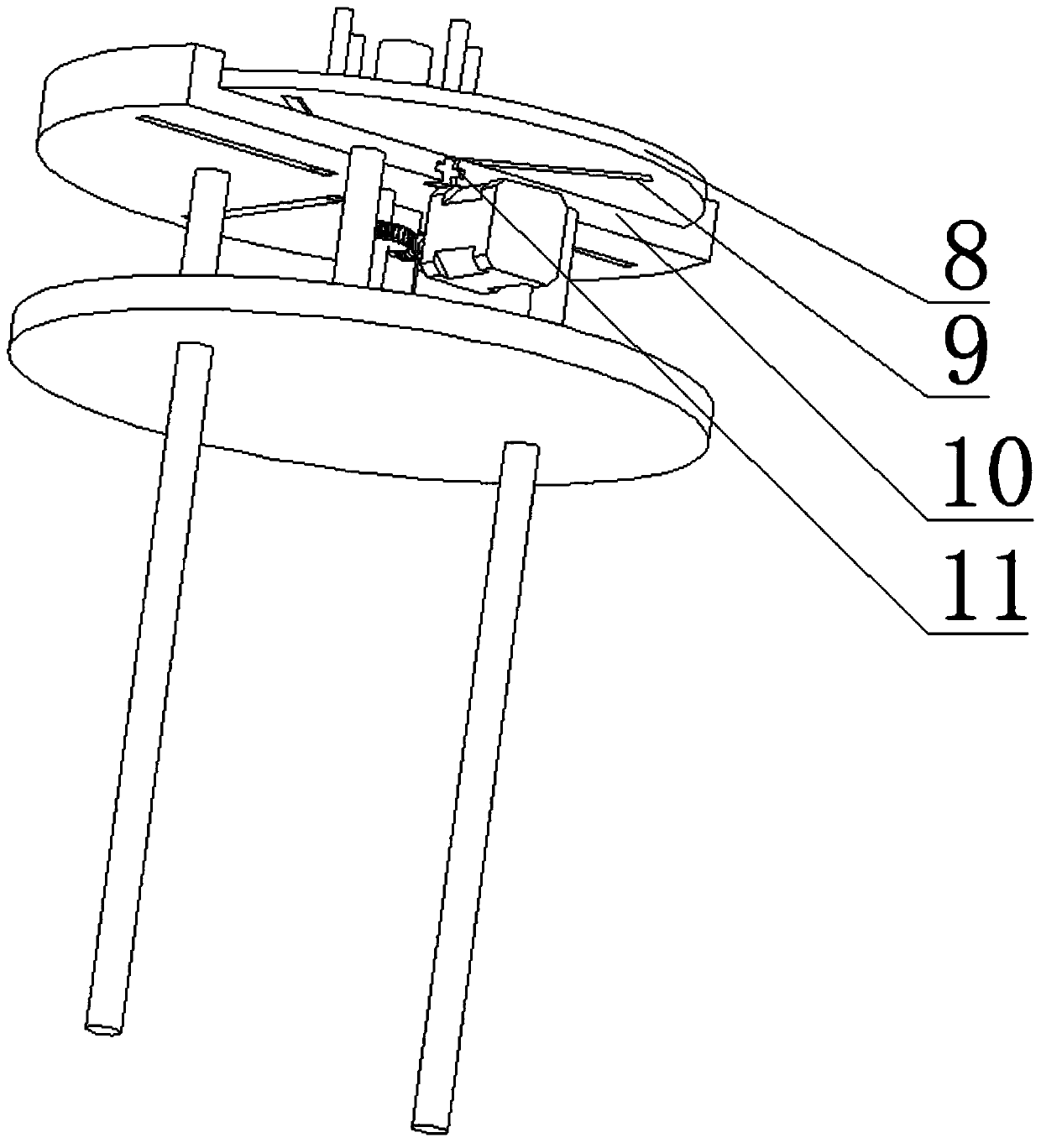

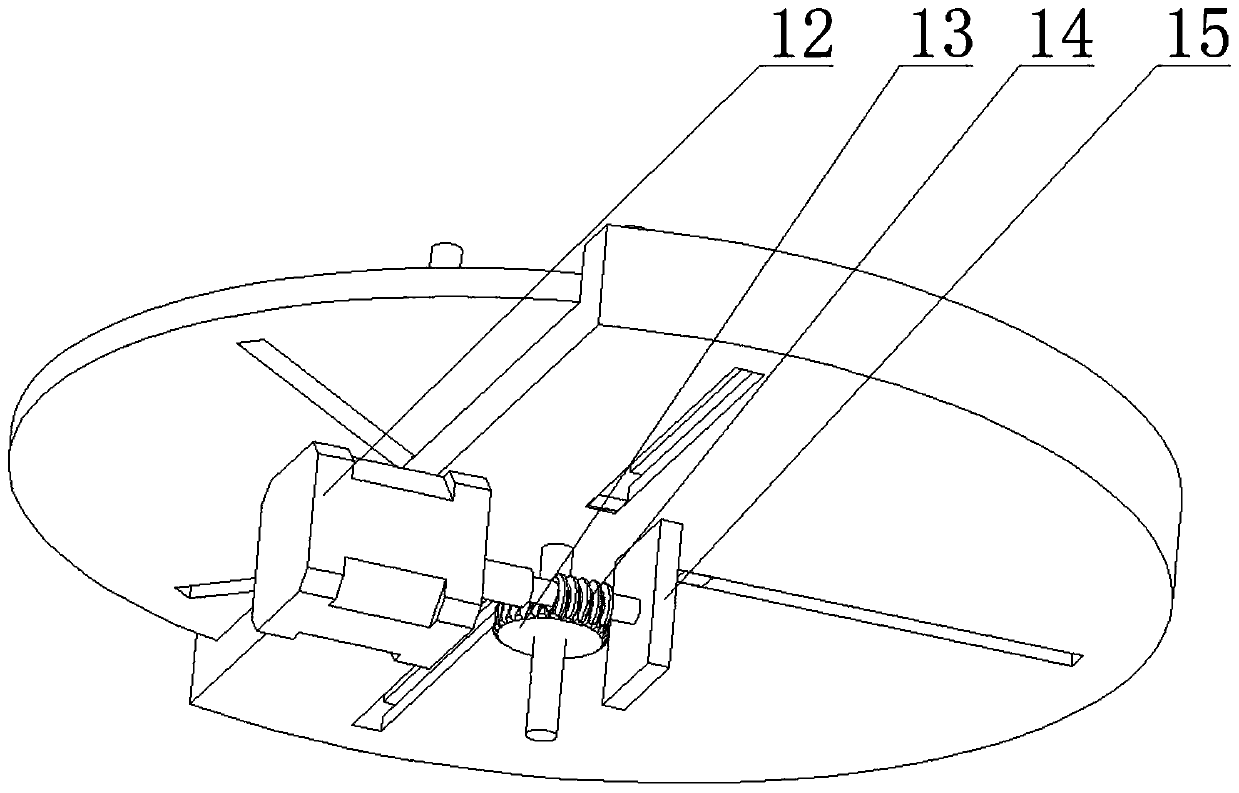

[0032] Such as Figure 1-Figure 9 As shown, the present invention includes an L-shaped plate 3, the L-shaped plate 3 is fixedly connected to the horizontal plate 2, the L-shaped plate 3 is fixedly connected to a symmetrical electric push rod-6, and the push rod of the symmetrical electric push rod-6 The ends of the rods are respectively fixedly connected to the first circular plate 4, and the first circular plate 4 is fixedly connected to one end of a group of circular rods 5 evenly distributed along the circumferential direction, and the other end of each of the circular rods 5 is respectively fixedly connected to the third circular plate 10, The third disc 10 is fixedly connected to the ring 7, the third disc 10 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com