Roller frame for long rod polisher

A roller frame and grinding machine technology, which is used in grinding machines, machine tools designed for grinding the rotating surface of workpieces, grinding/polishing equipment, etc., to achieve the effect of improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

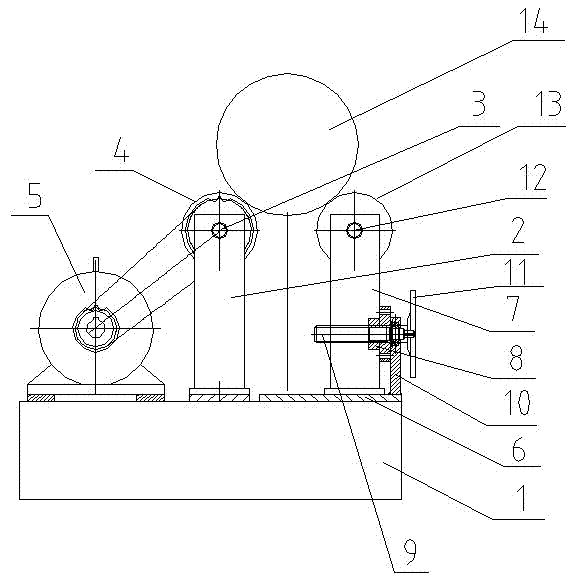

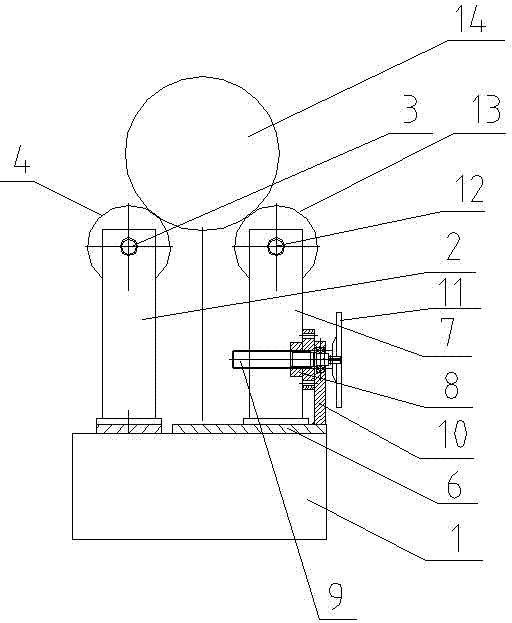

[0010] figure 1 As shown, the present invention arranges a group of fixed roller brackets 2 on the roller base 1 , and supports the first roller 4 on the fixed roller bracket 2 through the first rotating shaft 3 . A roller driving device 5 is also arranged on the roller base 1 , and the output end of the roller driving device 5 is in transmission connection with the wheel shaft 3 of the first roller 4 .

[0011] A slide rail 6 is set on the roller base 1, a slider type roller bracket 7 is connected on the slide rail 6, a nut 8 is connected to the lower part of the slider type roller bracket 7, the nut 8 is threadedly connected with a screw rod 9, and one end of the screw rod 9 passes through The bearing is connected on a stand 10, and the stand 10 is fixedly connected on the roller base 1, and the end of the screw rod 9 is connected with an adjustment handwheel 11.

[0012] A second roller 13 is supported by a second rotating shaft 12 at the upper end of the slider type rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com