Spinneret plate of melt-blowing mold

A technology of spinneret and mold, which is applied in the direction of spinneret assemblies, textiles and papermaking, etc. It can solve the problems of low output, slow output speed, and increased output of meltblown cloth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

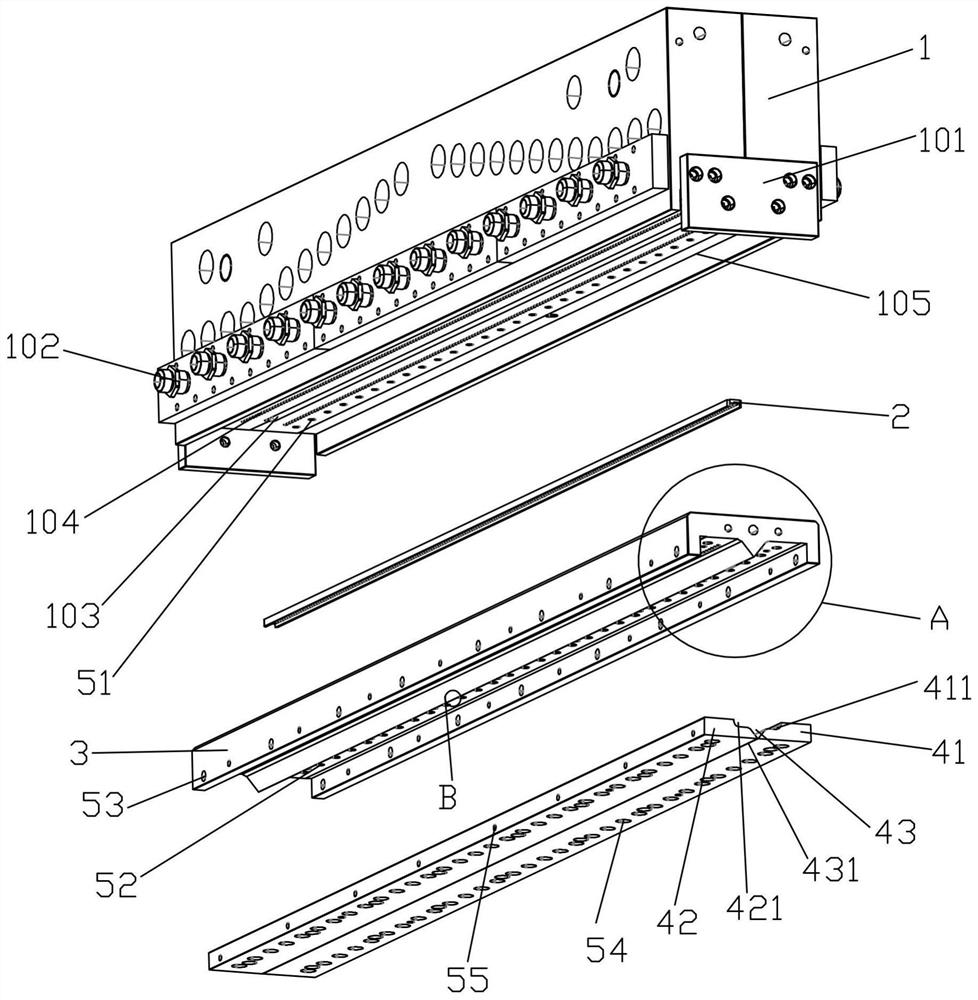

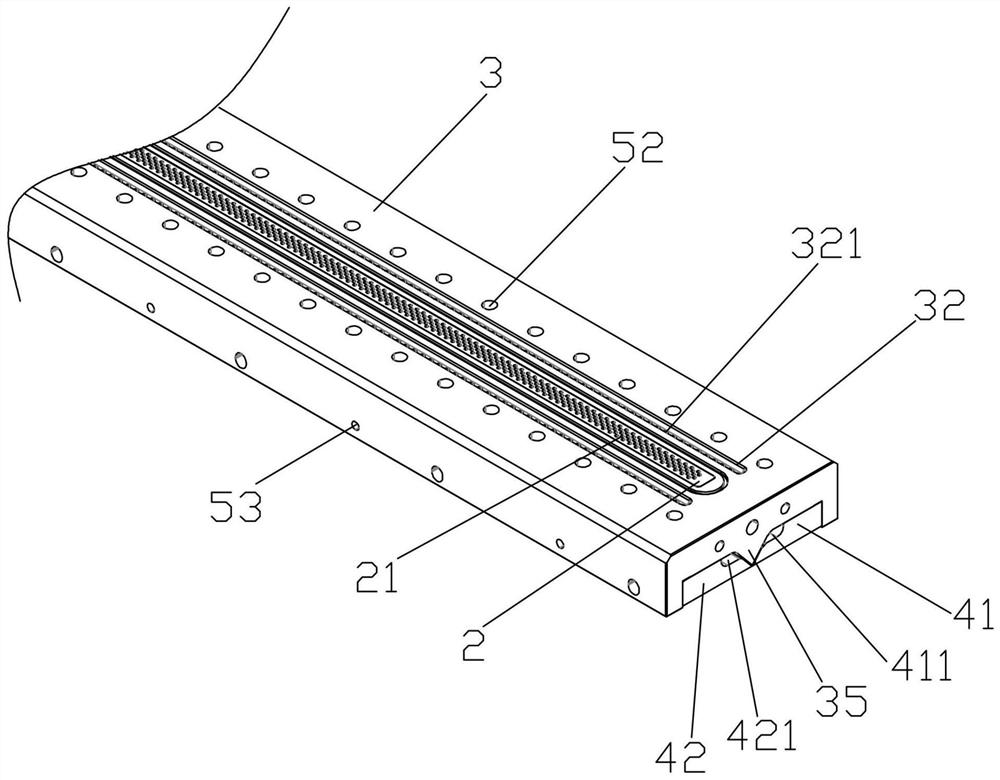

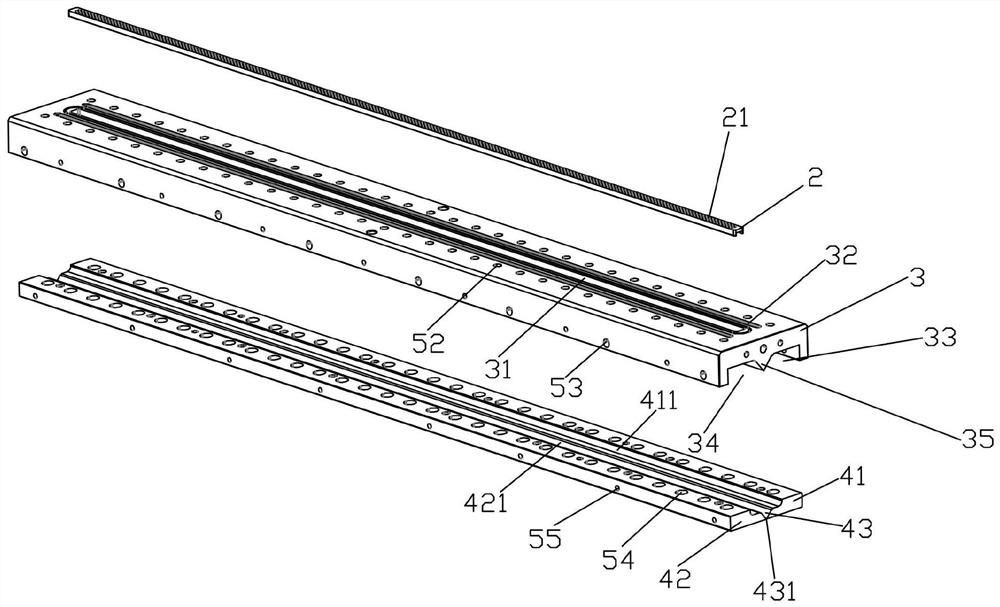

[0021] Embodiment: a kind of spinneret of melt-blown mold, as Figure 1-Figure 7 As shown, it includes a melt blowing mold 1, an injection air pressure device 102 and a fixed plate 101. The fixed plate 101 is connected to the front and rear sides of the melt blow mold 1, and the injection air pressure device 102 is arranged at the bottom of the left and right sides of the melt blow mold 1. The bottom surface of the mold 1 is provided with a material outlet 103 and a plurality of top air outlets 104, and a plurality of top air outlets 104 are respectively arranged on the left and right sides of the material outlet 103, and the top air outlet 104 extends the left and right sides of the material outlet 103. The sides are longitudinally arranged, and the bottom of the melt-blowing mold 1 is provided with a spinneret 3, and the top of the spinneret 3 is provided with a distributing chamber 31 and two through grooves 32, and the distributing chamber 31 and the bottom protruding strip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com