Waste heat boiler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

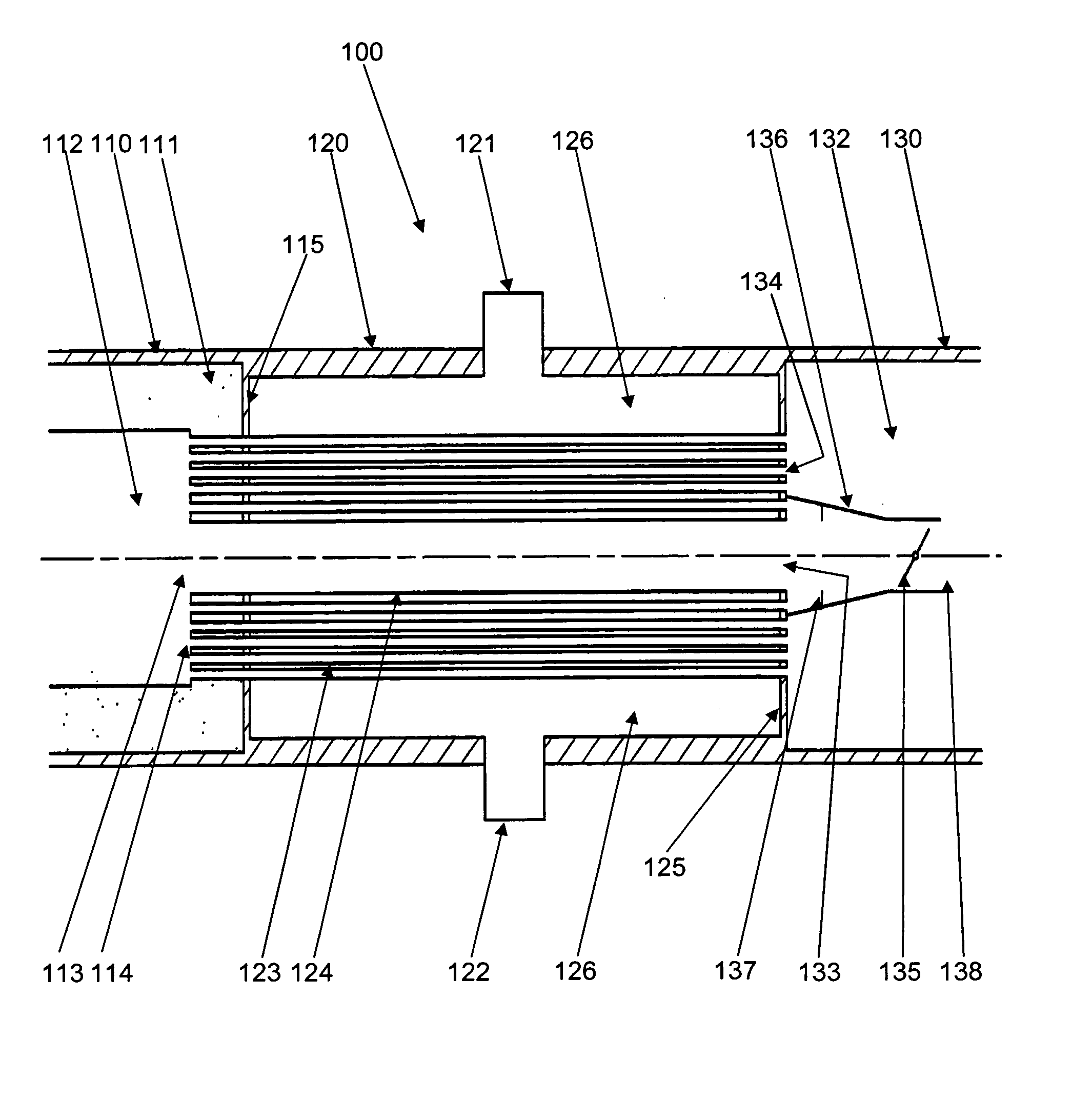

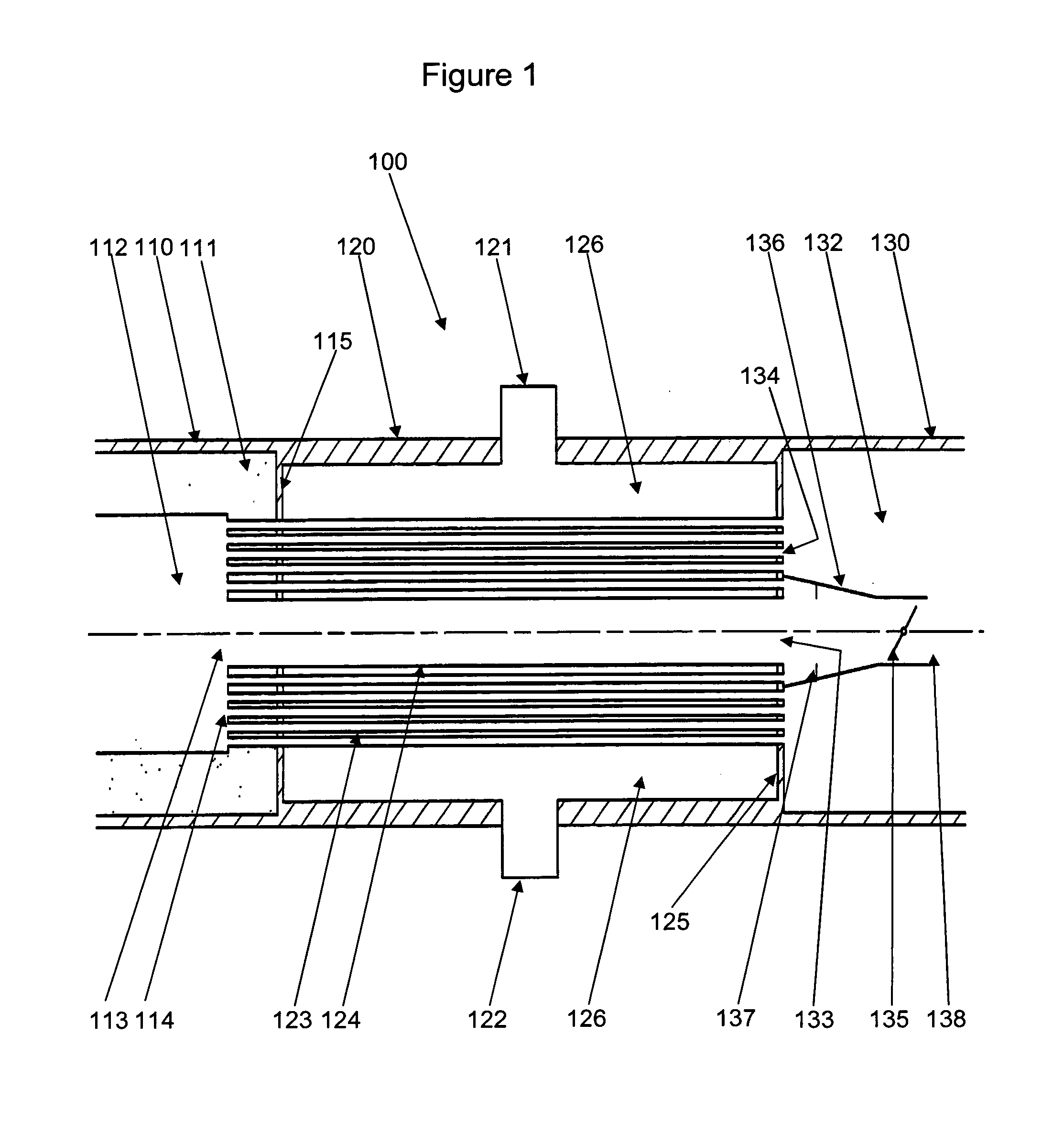

[0061]FIG. 1 is a cross sectional view of the waste heat boiler 100 according to an embodiment of the invention. The waste heat boiler comprises a first shell part, process gas inlet end 110; a second shell part, heat exchange section 120 and a third shell part, process gas outlet end 130; all having a substantially cylindrical shape and substantially the same diameter, but as can be seen on the figure, not necessarily the same material thickness. The material thickness as well as the choice of material can be varied depending on the process conditions.

[0062]A first tube sheet, process gas inlet end 115 separates the first shell part from the second shell part. Likewise, a second tube sheet, process gas outlet end 125 separates the second shell part from the third shell part. Thus the first shell part and the first tube sheet encloses the process gas inlet section 112; the second shell part along with the first and the second tube sheet encloses the heat exchange section 126; and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com