Brake system having simultaneous or partially simultaneous pressure generation and reduction in the wheel brakes from differing wheel cylinder pressure levels

A technology of wheel brakes and braking systems, applied in the direction of brakes, brake transmissions, vehicle components, etc., can solve the problems of not providing pressure generation, pressure reduction, pressure increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

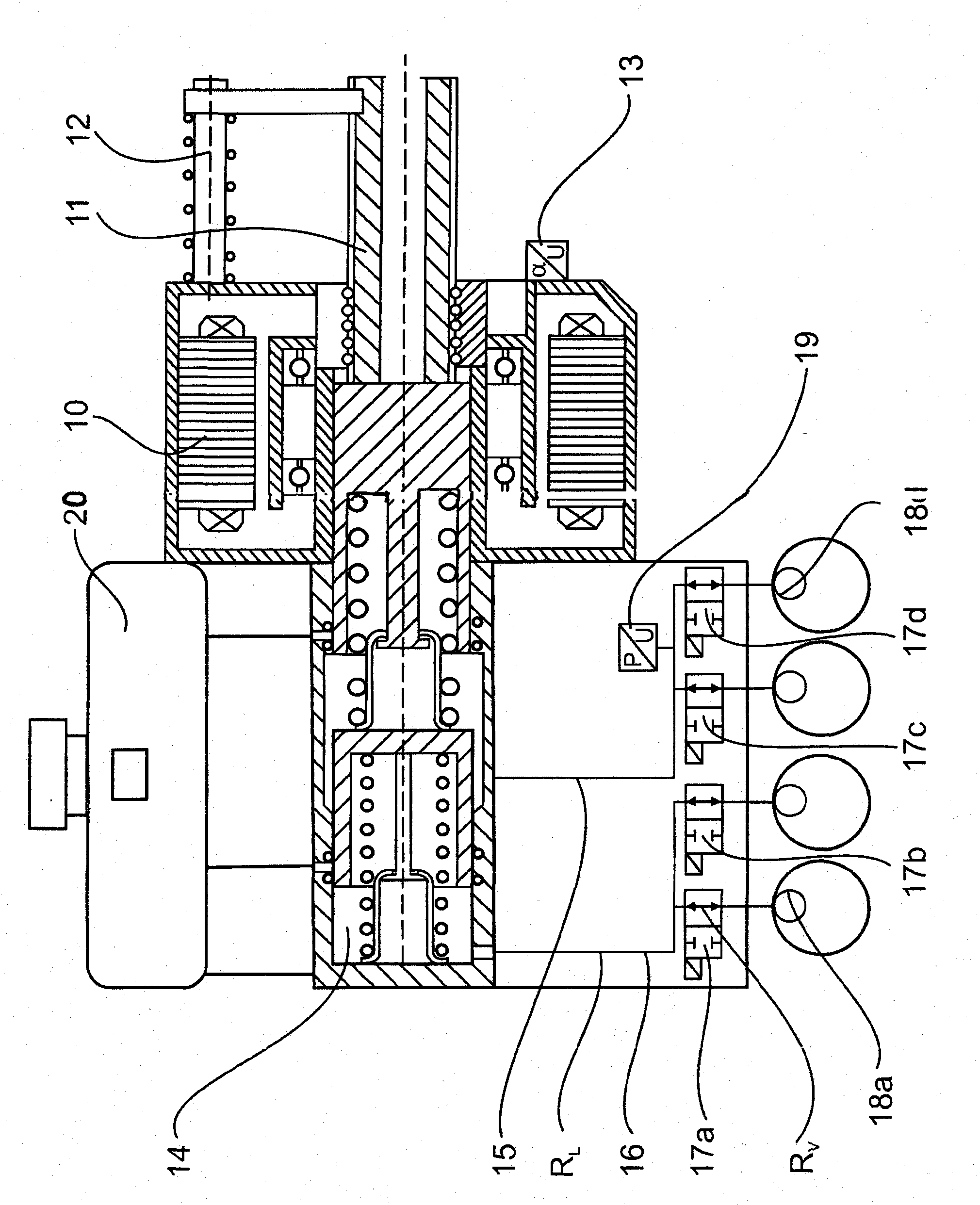

[0034] figure 1 The basic structure of the braking system according to the invention is shown, which consists of HZ or THZ 14, EC motor 10, main shaft 11 for driving the pressure rod piston, main shaft reset device 12 and rotational angle sensor 13 which determines position of the piston and detect rotor position or piston travel.

[0035] If the piston receives an adjustment command to generate a specific pressure, a corresponding piston movement is generated by the pre-recorded pressure-volume characteristic stored in the characteristic map, by the position sensor 13 and the pressure sensor 19 in the pressure rod circuit. In the case of a subsequent brief constant pressure, which is generally the case during a braking operation, a correlation comparison is carried out on the basis of new measurement data using the stored characteristic map data. If there are deviations, when the vehicle is at a standstill at a later time, the pressure-volume characteristic is recorded again...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com