Magnet valve, and driver assistance device comprising such magnet valve

A solenoid valve and armature technology, applied in the field of solenoid valves, can solve the problems of increasing the minimum adjustment time, reducing the movable speed of the solenoid valve, reducing the maximum adjustment speed of the solenoid valve, etc., and achieving the effect of high adjustment speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

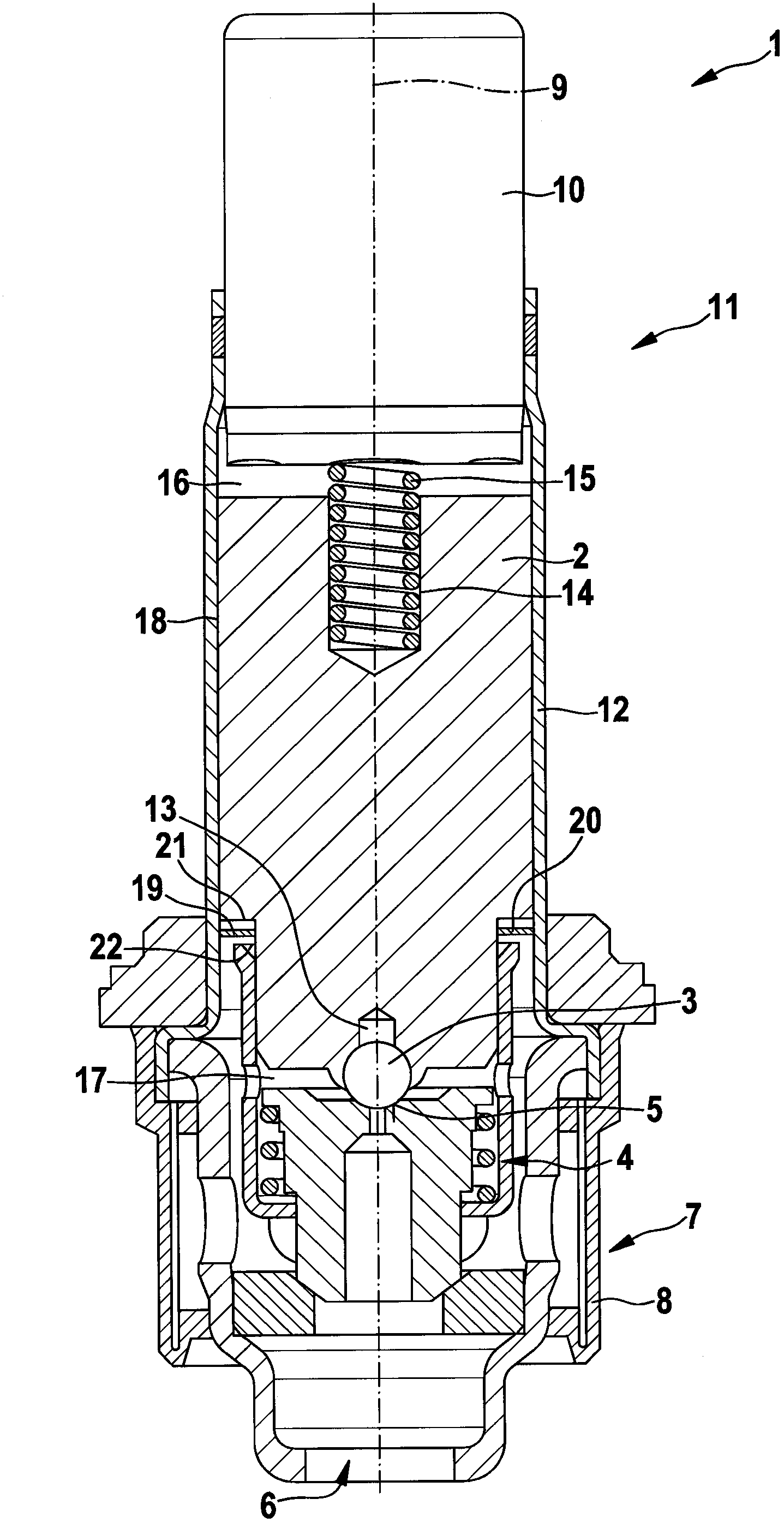

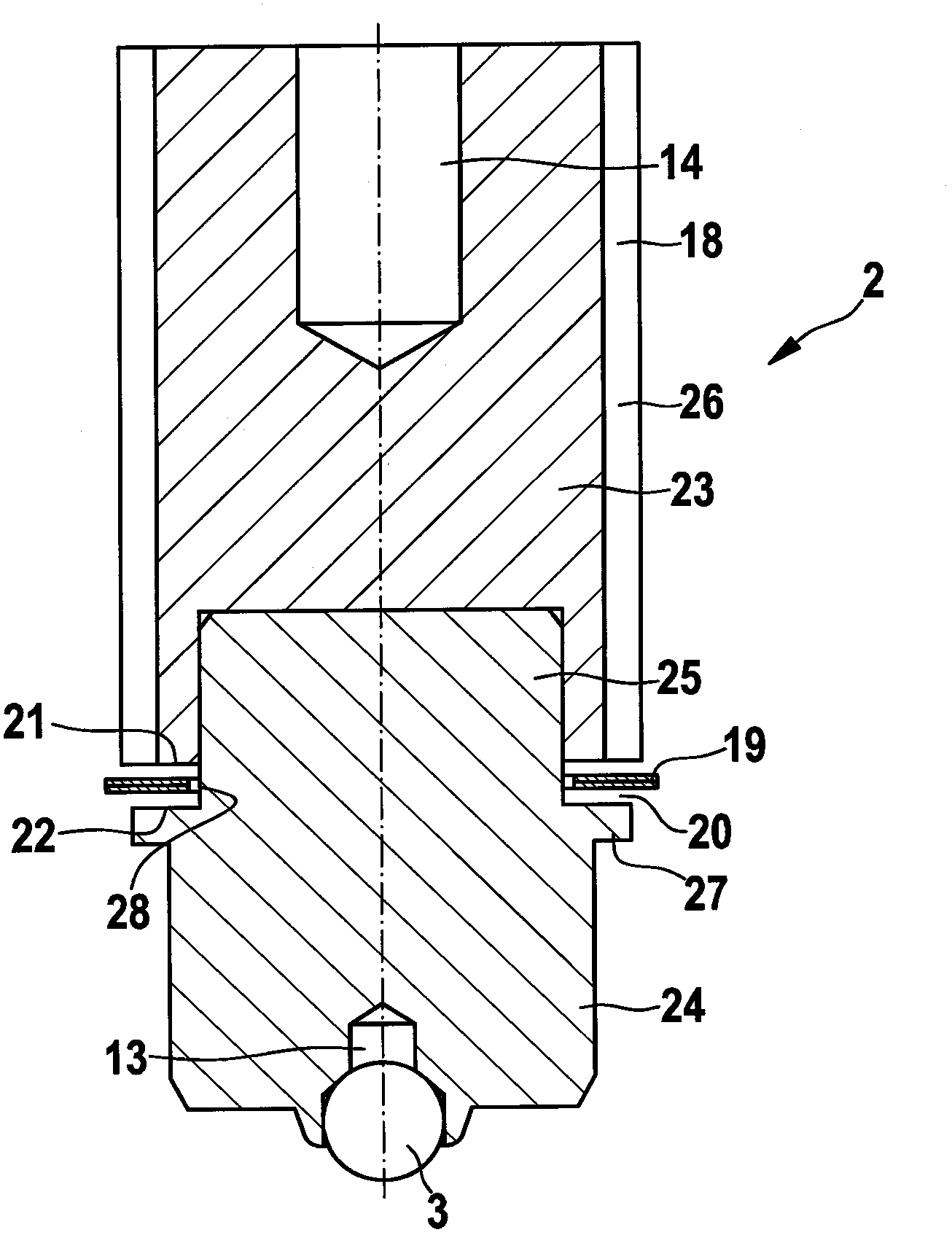

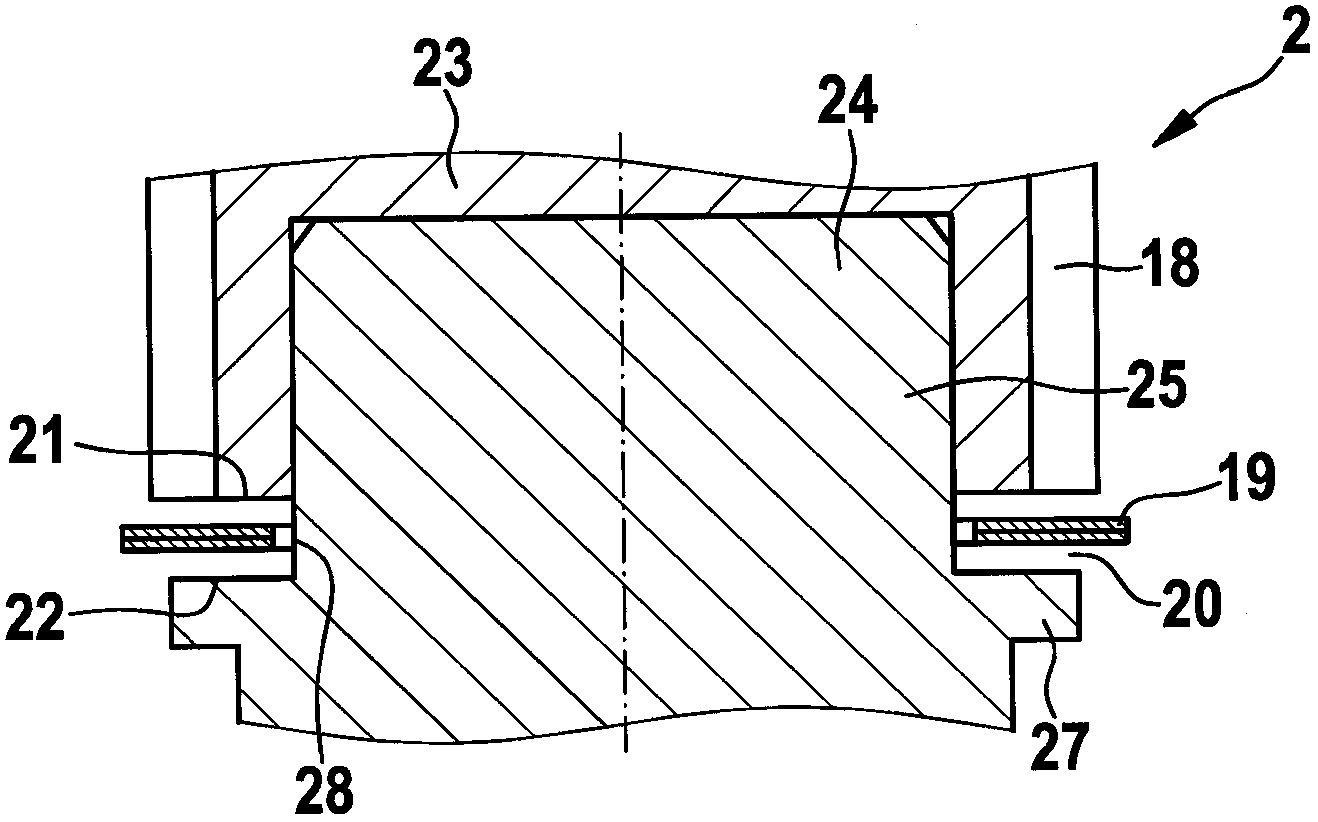

[0024] The figure shows a solenoid valve 1 , which is, for example, a component of a driver assistance device not shown here. The solenoid valve 1 has an armature 2 operatively connected to a sealing element 3 of the solenoid valve 1 . The sealing element 3 cooperates with a valve seat 5 formed in the valve body 4 to open or shut off the flow connection between the inlet connection 6 and the outlet connection 7 of the solenoid valve 1 . In the exemplary embodiment shown here, a filter 8 is assigned to the outlet connection 7 . Of course, a filter (not shown here) can additionally or alternatively be assigned to the inflow connection 6 . Depending on the arrangement of the inflow port 6 and the outflow port 7 , the solenoid valve 1 shown here is designed for axial inflow and radial outflow (relative to the longitudinal axis 9 of the solenoid valve 1 ). Of course, however, the inflow and outflow directions can also be arranged arbitrarily.

[0025] In addition to an armature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com