Variable flow resistance

A fluid and flow technology, applied in the field of variable flow resistance, can solve the problems of cooling system operation decline and inability to alleviate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

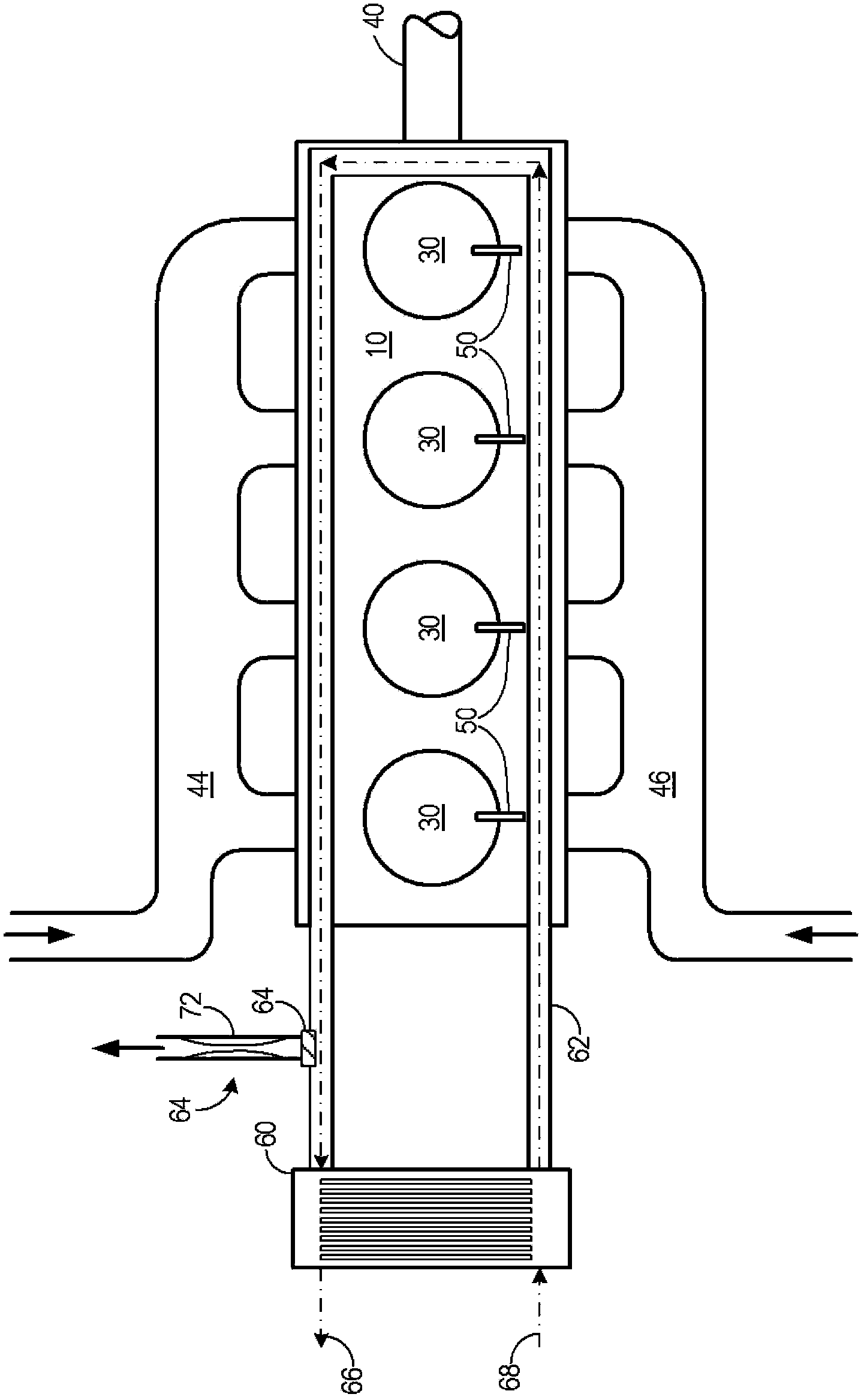

[0015] In internal combustion engines, since the cooling system may exhibit high pressure due to pressurization and high temperature, one or more purge lines may be provided to relieve the pressure in the cooling system. Failure to relieve such high pressures may result in degradation of cooling system operation, for example, because heat removal and distribution may be limited. It may further be desirable to regulate the pressure of gas or other fluid flowing through the purge line. As used herein, "fluid" may equally refer to a substance in either a gaseous or a liquid state.

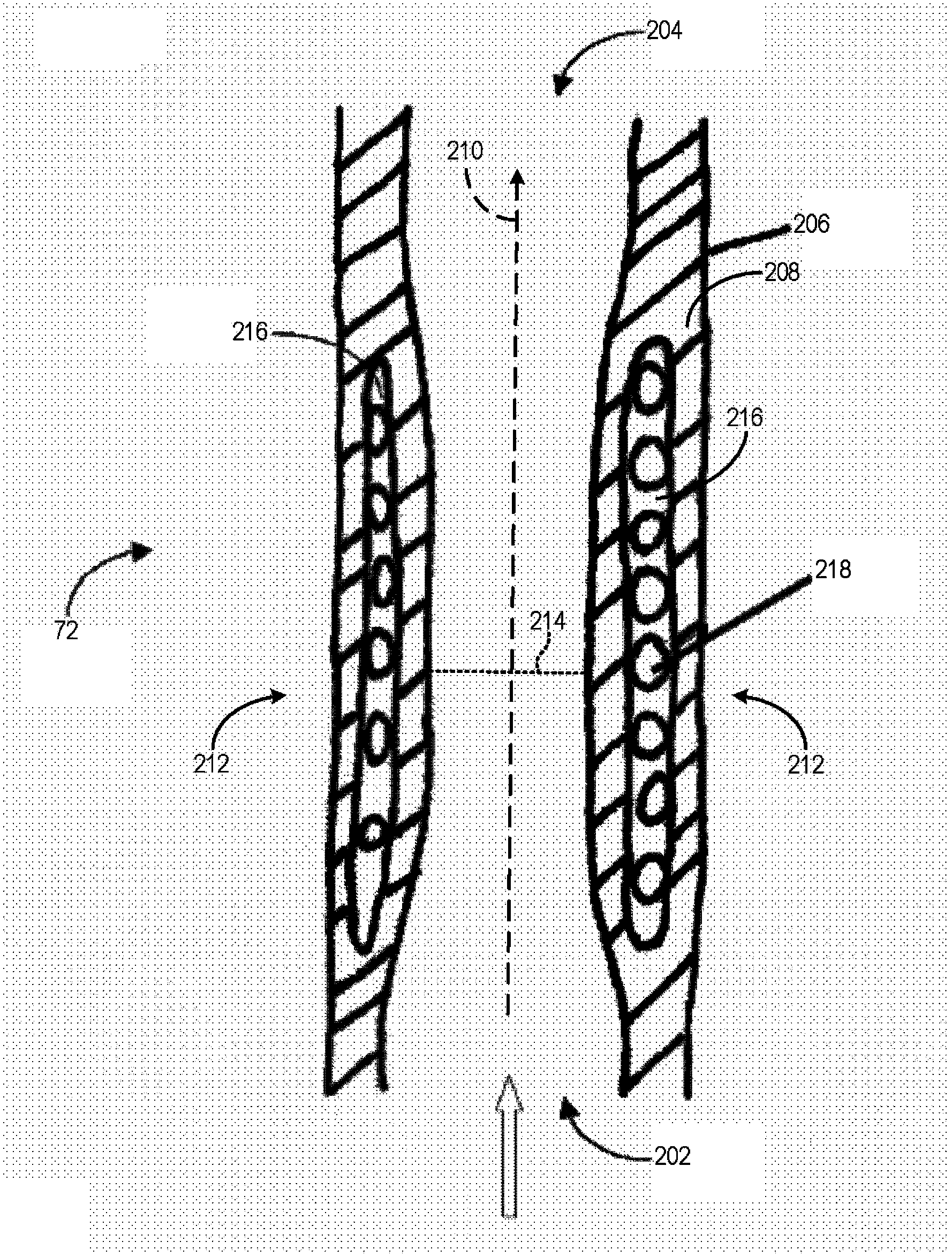

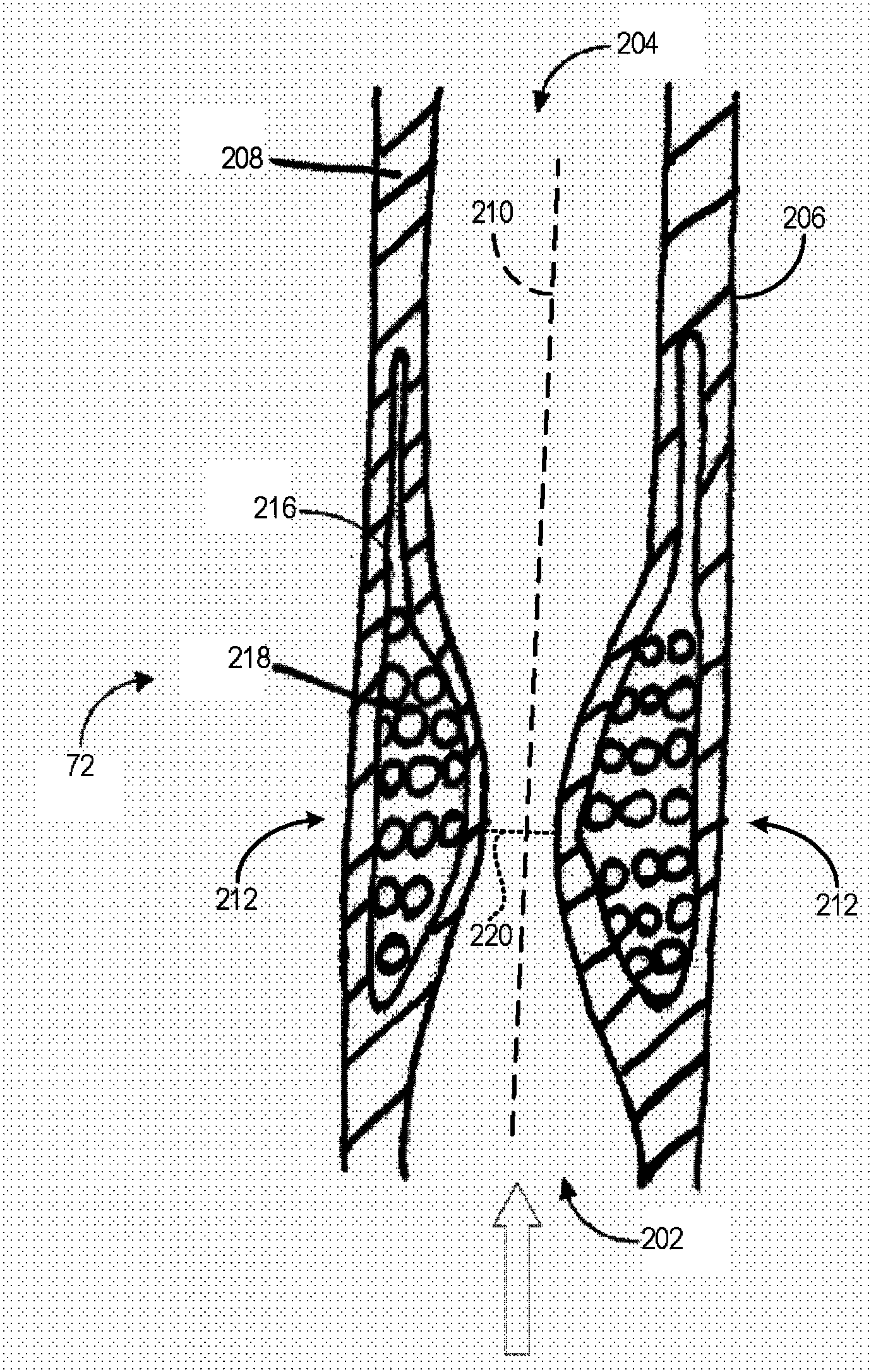

[0016] Various systems are provided for adjusting the flow cross section of fluid flowing through a fluid line. In one embodiment, a system includes a fluid inlet, a fluid outlet, and a hollow body housing forming an elongated hollow body with fluid conduits, the hollow body housing fluidly connecting the fluid inlet to the fluid outlet. The system may further comprise a cross-section control device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com