U-shaped tubular condenser of vertical type spiral baffle plate

A technology of spiral baffles and baffles, which is applied to steam/steam condensers, heat exchanger shells, lighting and heating equipment, etc., can solve the problems of limited application, improve the condensation heat transfer coefficient, and avoid liquid Gathering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

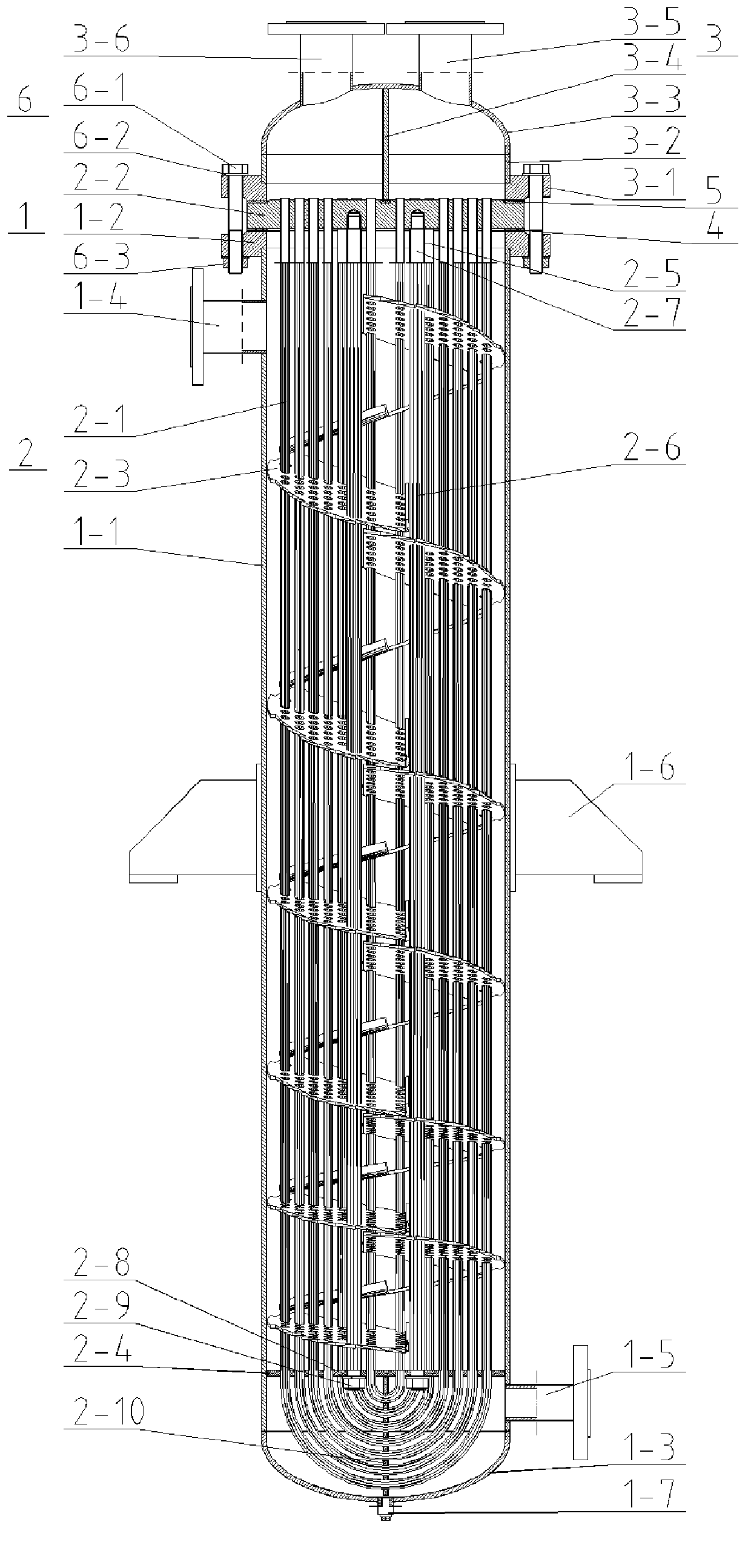

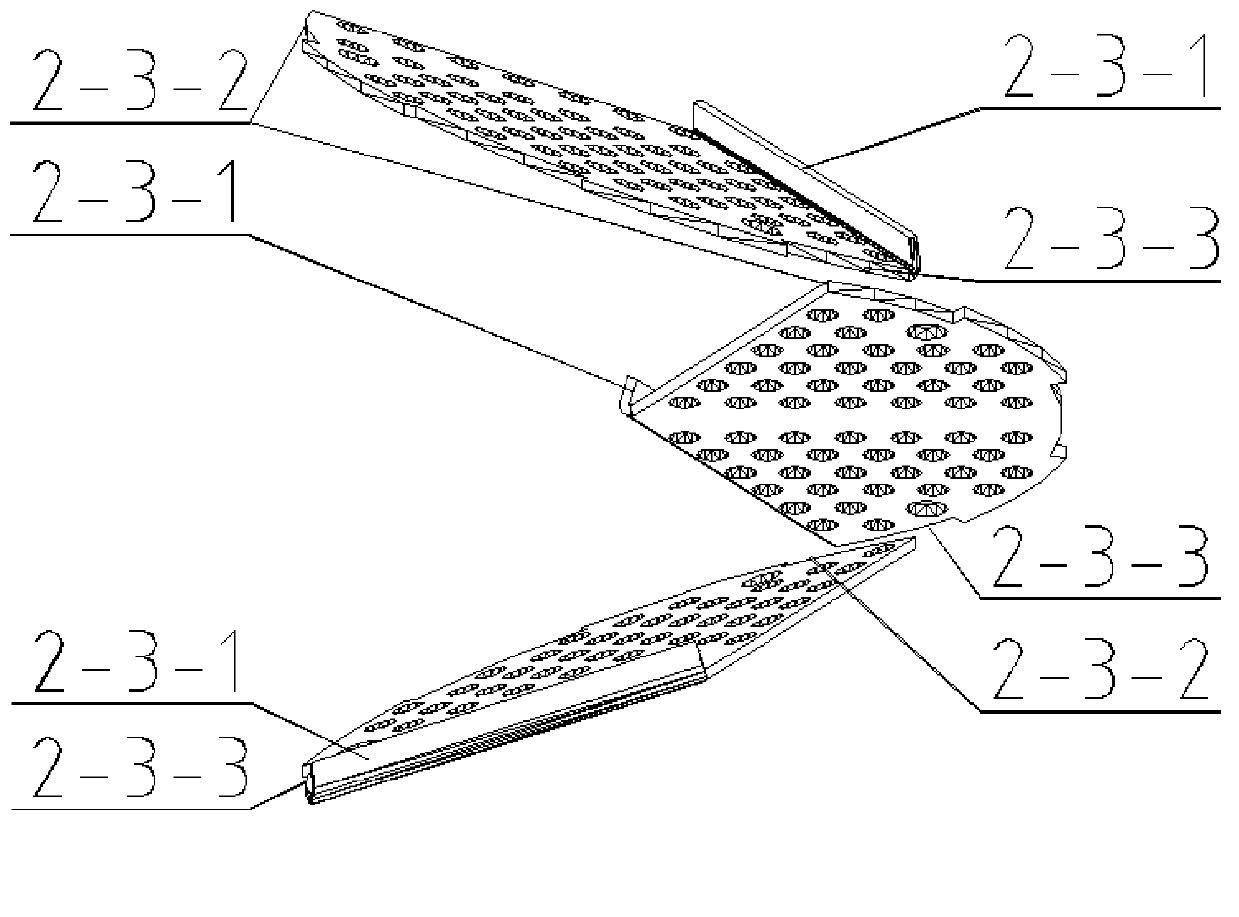

[0016] Examples see figure 1 , a vertical spiral baffle U-shaped tube condenser, comprising a shell assembly 1, a tube bundle assembly 2, an upper head assembly 3, an annular gasket 4, a double-chamber gasket 5 and a fastener group 6; The shell assembly 1 includes a cylinder 1-1, a flange A1-2, a lower head 1-3, a shell-side fluid inlet connection 1-4, a shell-side fluid outlet connection 1-5, legs 1-6, Bottom interface and plug 1-7; the upper head assembly 3 includes flange B3-1, straight pipe section 3-2, upper head 3-3, longitudinal partition 3-4, pipe side fluid inlet connection 3- 5. Tube side fluid outlet connection 3-6; the tube bundle assembly 2 includes a U-shaped tube bundle 2-1, a tube plate 2-2, a spiral baffle group 2-3, an annular plate 2-4, and a single-head inclined plane fixed distance Sleeve group 2-5, double-headed inclined-plane fixed-distance casing group 2-6, tie rod 2-7, washer B2-8, nut B2-9 and spacer group 2-10; the tube bundle assembly 2 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com