Method for the treatment and prevention of asphaltene-paraffin-vax precipitates in oil-wells, wellheads and pipelines by the use of biocolloid suspensions

a technology of asphalteneparaffin and biocolloid suspension, which is applied in the direction of fluid removal, wellbore/well accessories, drilling composition, etc., to achieve the effects of increasing viscosity, and reducing the number of particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention relates to a method for the removal of asphaltene-paraffin-vax precipitates and prevention of formation thereof on surfaces in contact with crude oil comprising

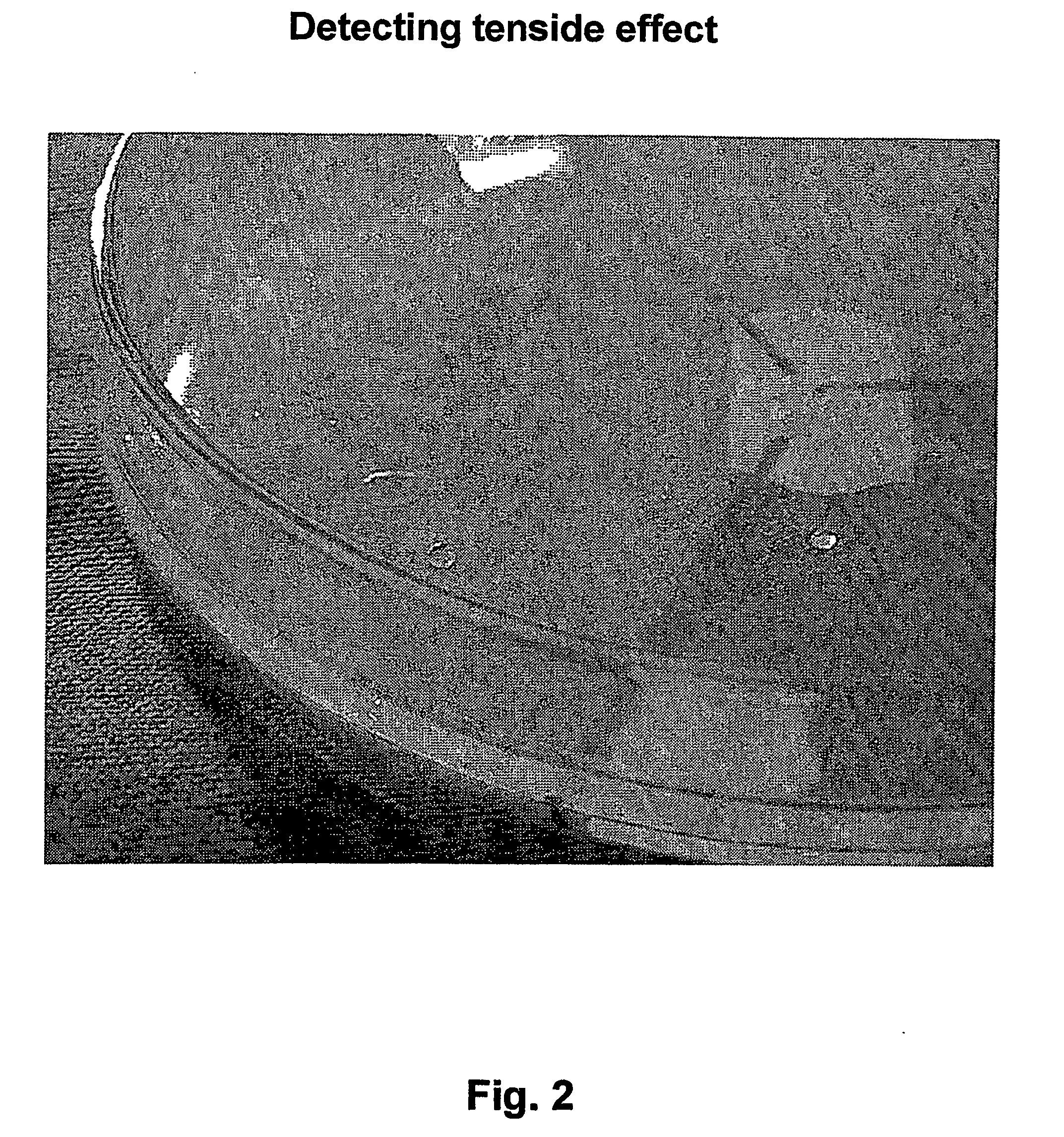

[0049] a) adding tensides, materials for increasing viscosity, and microorganism(s) capable of breaking down crude oil components or derivatives and producing at least one type of tenside, to the surface, optionally together with additives required for the reproduction of said microorganisms;

[0050] b) providing an appropriate temperature for the microorganisms after the addition of the materials in step a);

[0051] c) allowing the microorganisms to reproduce and act for a predetermined period of time on the surface;

[0052] d) checking the results of the treatment; and

[0053] e) optionally repeating steps (a) to (d) at least once more, preferably at least three more times.

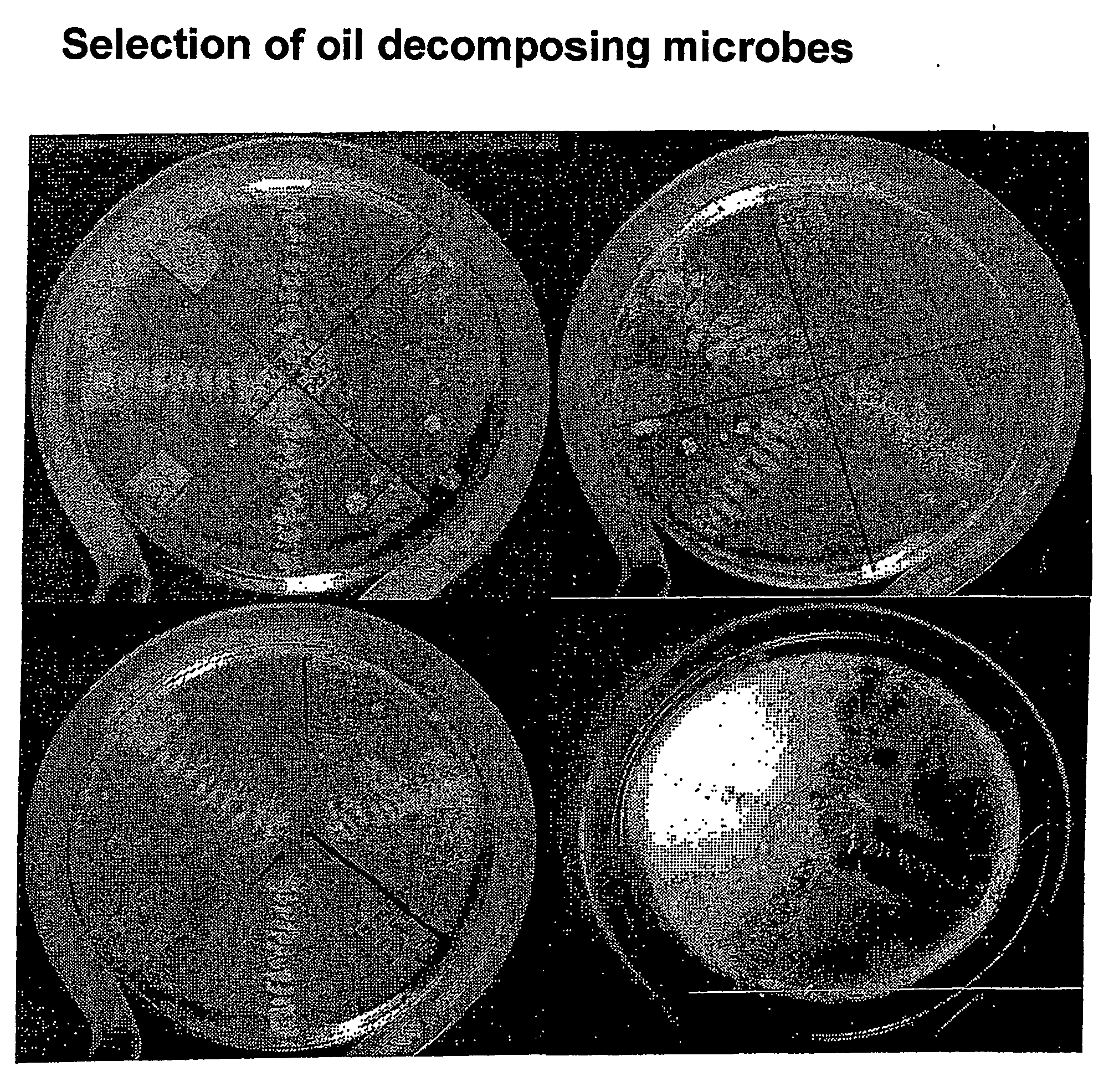

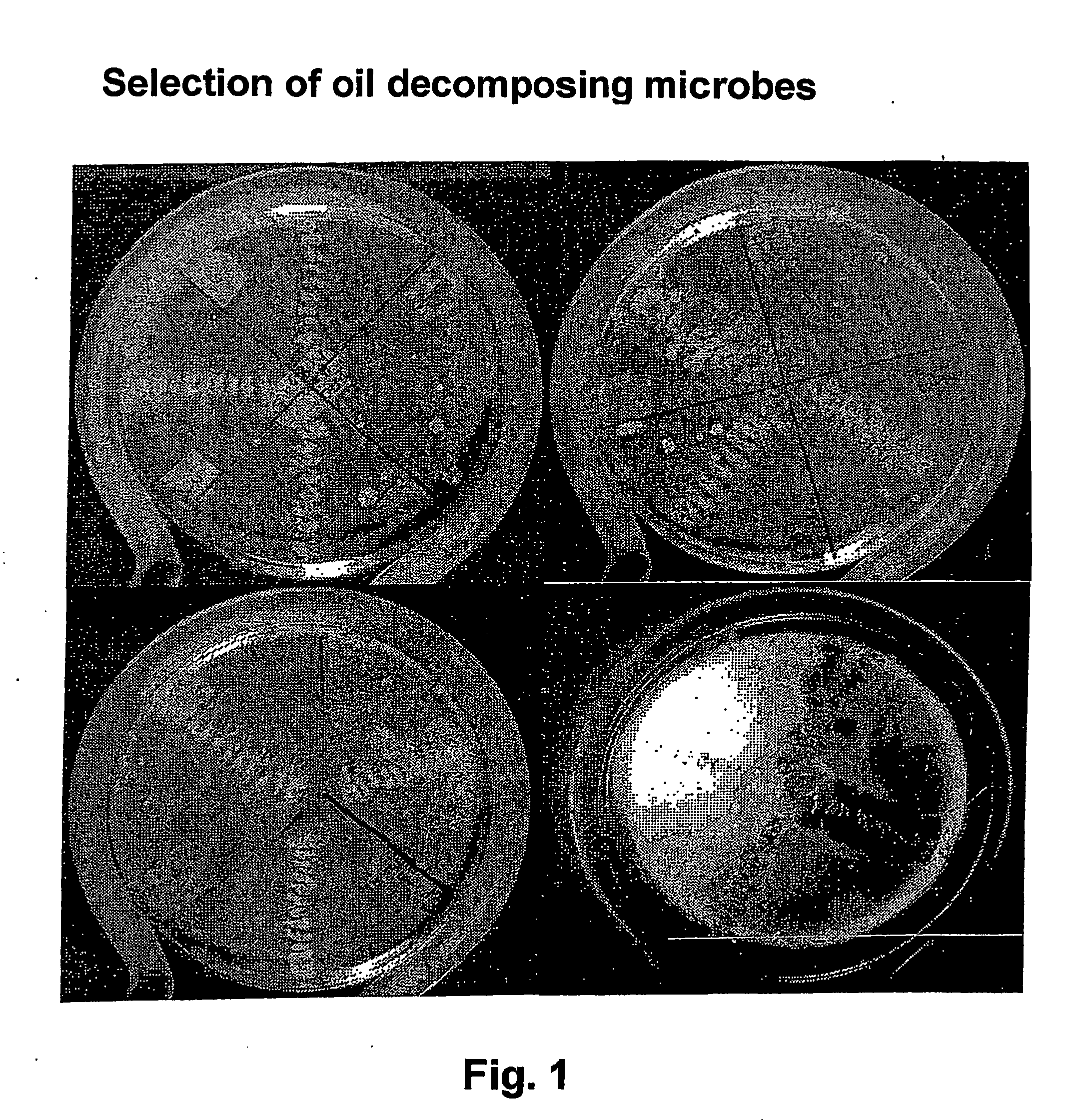

[0054] According to the invention, microorganism(s) capable of decomposition, washing-off and inhibition and removal of the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com