Silicon-based lithium storage material and preparation method thereof

A silicon-based storage and lithium storage technology, applied in the field of lithium-ion batteries, can solve the problems of difficulty in forming silicon-based lithium storage materials, poor first coulomb efficiency and poor cycle characteristics of silicon-based lithium storage materials, and achieves improved initial charge and discharge coulombs. Efficiency, improvement of characteristics, effect of improving cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present application also provides a method for preparing a silicon-based lithium storage material, including:

[0048] Step S1: providing a first mixture, the first mixture includes at least the elemental state of silicon and the +4 oxidation state of silicon, the first mixture includes a doping element R, and the doping element R includes at least I, One of the elements of the main group II, III, and where C R is the mole number of doping element R, is the number of moles of silicon elements with a valence between 0 and 4;

[0049] In the embodiment of the present application, the single state of silicon is, for example, polysilicon. The +4 oxidation state of silicon is, for example, silicon dioxide, and the raw material containing silicon dioxide is, for example, quartz, optionally, for example, β-type quartz. The +4 oxidation state of silicon can also be a silicate, for example, the general formula is MySiO 3 Compounds, where 1≤y≤2; M is I, II, III main gr...

Embodiment 1

[0077] A first mixture was prepared comprising Component A (polysilicon), Component B (beta-type quartz), and Component C (MgCO 3 ), the doping element R is based on the Mg element in component C, and the molar ratio of component B to component A (marked as Si(+4) / Si(0), representing +4 valence in component B The molar ratio of silicon to 0-valent silicon in component A) is 5:3, and the molar ratio of the Mg element in component C to the Si element in component A and component B is 0.5;

[0078] Under the protection of argon, the first mixture was heated to 2600°C in a molten state and then cooled to room temperature at a cooling rate of 20°C / S (the first mixture in the molten state was poured on a fast roller, passed through the roller The centrifugation of the first mixture in the molten state is separated from the roller to obtain a flaky cooling product), and then the flaky cooling product is pulverized to form a powder with a median diameter of 4 D, Then a 300 nm amorp...

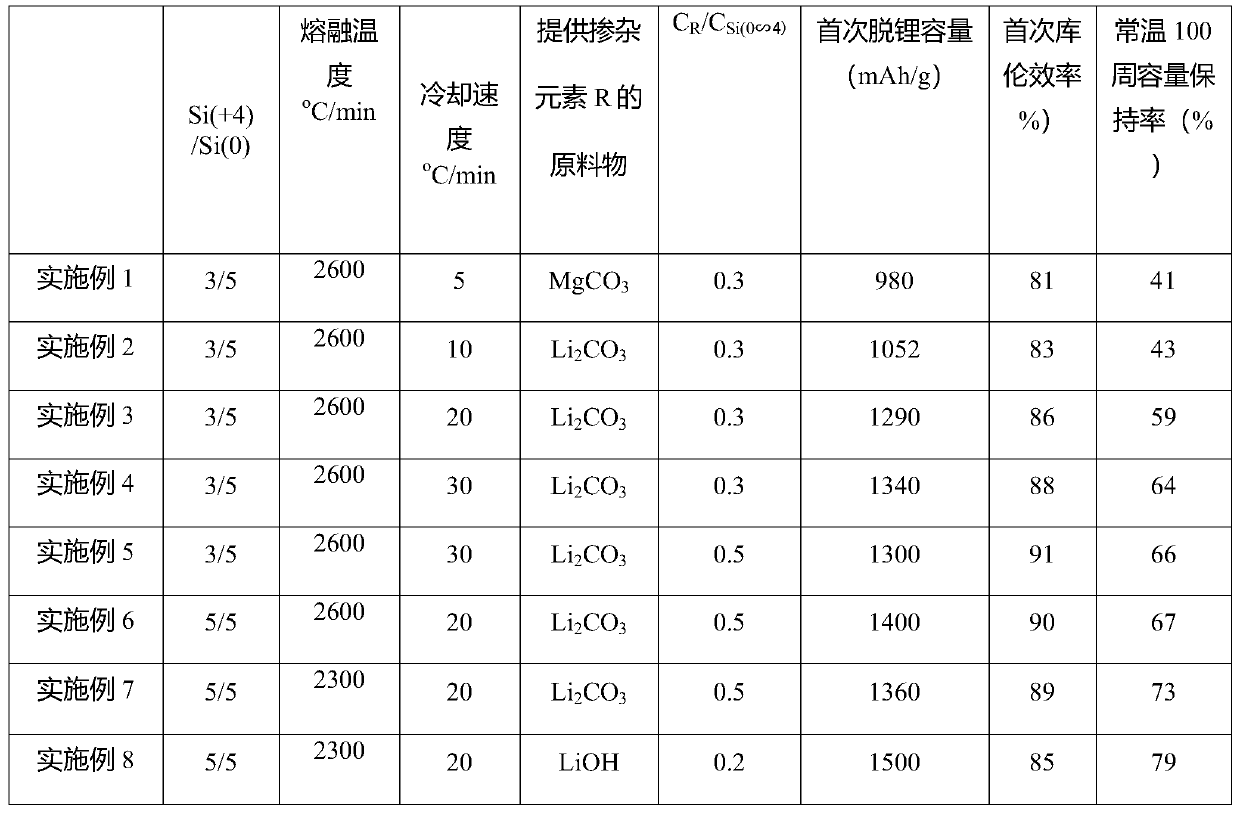

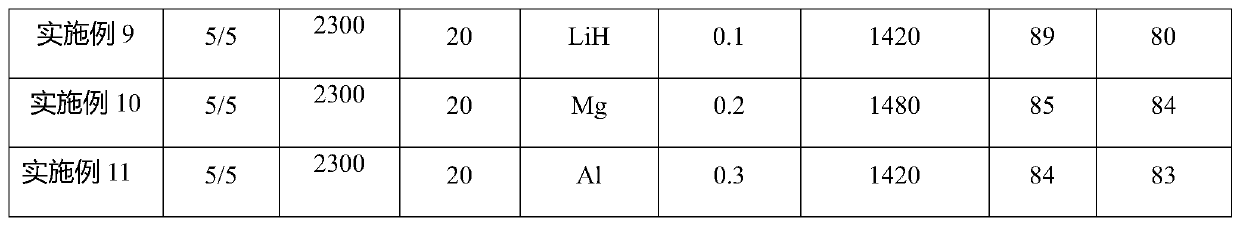

Embodiment 2~ Embodiment 11

[0080] The specific process description refers to Example 1, and the specific process data and the performance parameters of the formed silicon-based lithium storage material are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com