Gas-phase packed bed discharge plasma generating device

A technology for discharging plasma and generating device, applied in the direction of plasma, electrical components, etc., can solve the problems of affecting the discharge situation, lack of discharge, affecting the effect of material modification, etc., and achieve the effect of real-time spectral detection and uniform degradation treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Oxygen plasma modified adsorption resin XAD-2

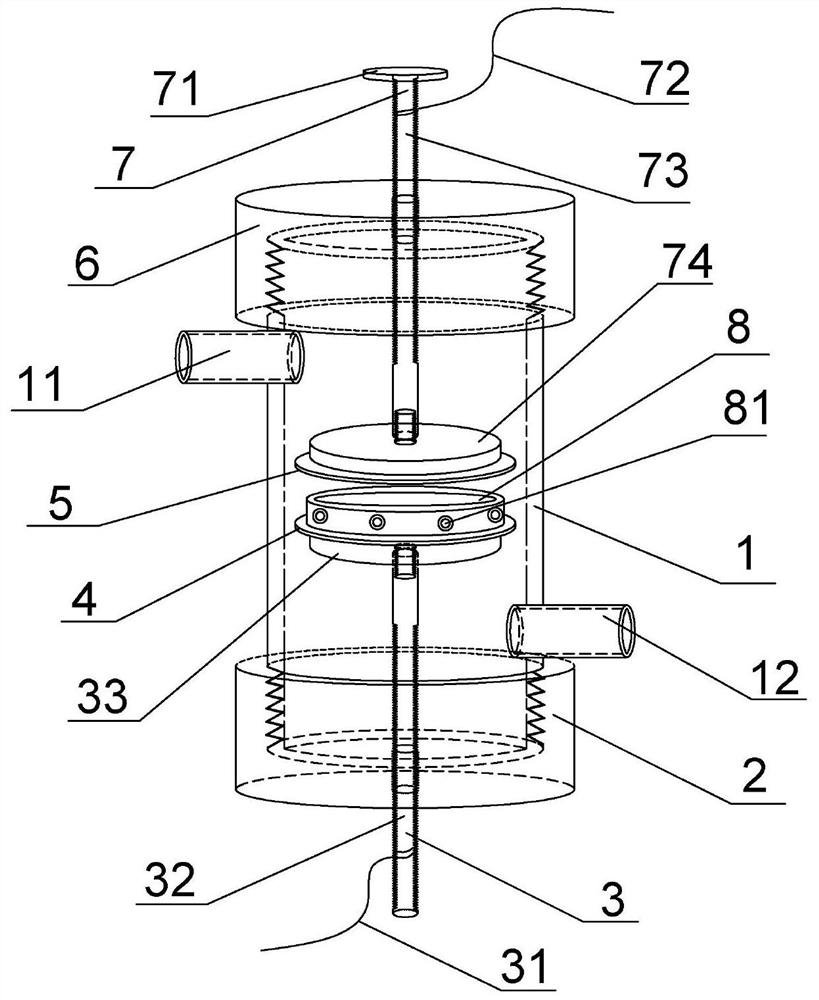

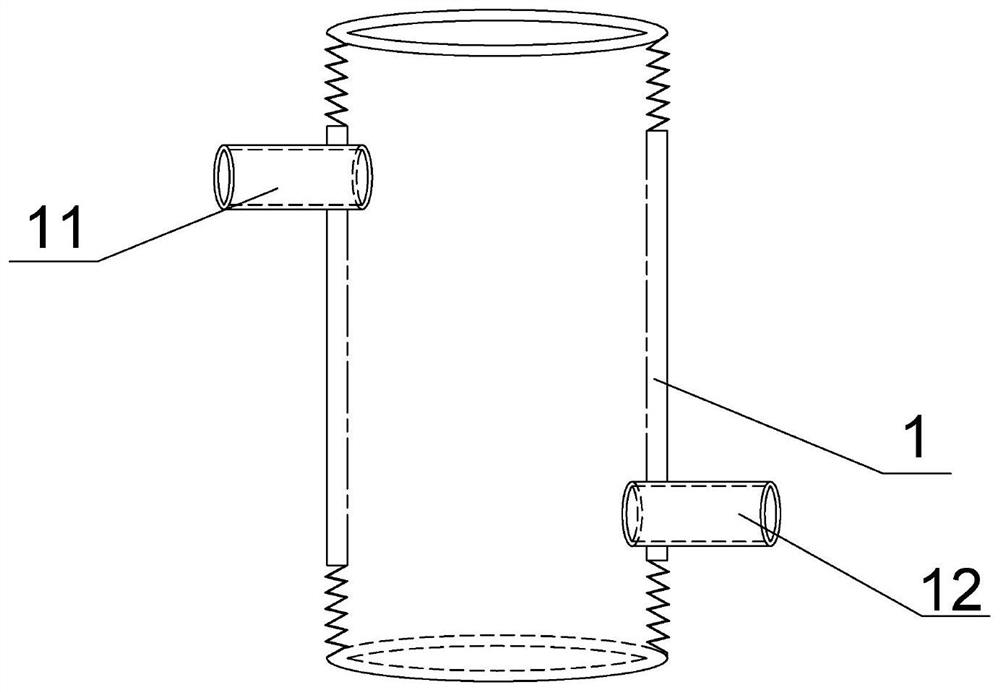

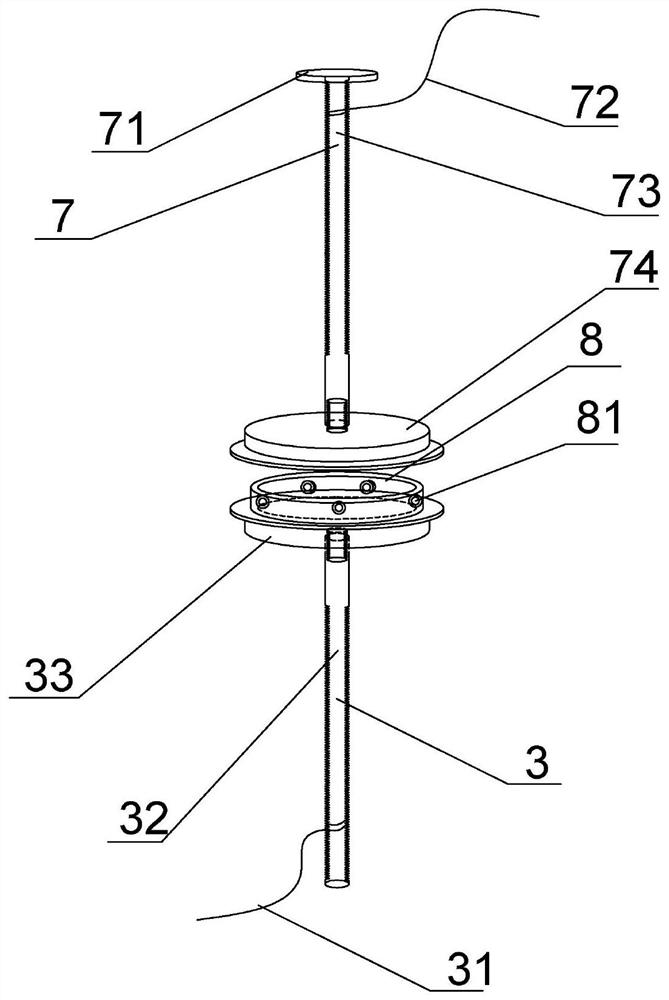

[0029] In the present embodiment, the plasma reactor housing 1 has a diameter of 14 cm and a height of 20 cm. The shape of the packed bed 8 is circular with air holes and a height of 3 mm. The diameter of the air holes 81 is 1.5 mm. The high-voltage electrode plate 74 and the low-pressure The electrode plates 33 are all stainless steel circular plates with a diameter of 8 cm and a thickness of 3 cm. The lower insulating dielectric plate 4 and the upper insulating dielectric plate 5 are ceramic sheets with a thickness of 0.5 mm. The amount of XAD-2 resin to be treated is 2 g . Oxygen is used as the discharge gas. Discharge parameters: the discharge voltage is 28kV, the frequency is 120Hz, the discharge time is 2-40min, and the intermittent time is 2min. The XAD-2 resin modified at each time point is tested for naphthalene adsorption performance, and the test result is: the adsorption performance of XAD-2 adsorp...

Embodiment 2

[0030] Embodiment 2: nitrogen plasma degrades trimethoprim solution

[0031] In this embodiment, the packed bed 8 is a square quartz glass tank with an inner diameter of 100*100, the packed bed height is 5 cm, the high-voltage electrode plate 74 is an array needle electrode, and the distance between every two needle electrodes is 6 mm. 33 is a plate electrode, and the lower insulating dielectric plate 4 and the upper insulating dielectric plate 5 are ceramic sheets with a thickness of 0.5mm. Operating parameters: the discharge voltage is 30kV, the discharge frequency is 120Hz, nitrogen is the discharge gas, and the trimethoprim solution is tested after 10 minutes of discharge treatment. The test result is: the degradation efficiency of trimethoprim can reach 89.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com