Plasma fluidized bed for treating material under normal temperature atmosphere and method thereof

A plasma and atmospheric pressure technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as affecting the use efficiency of plasma fluidized beds, limiting the types of modified materials, affecting the scope of application, etc. Low cost, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

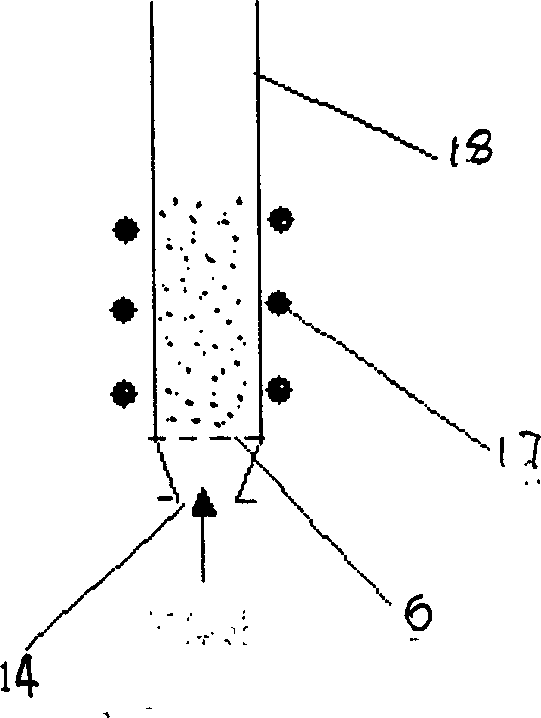

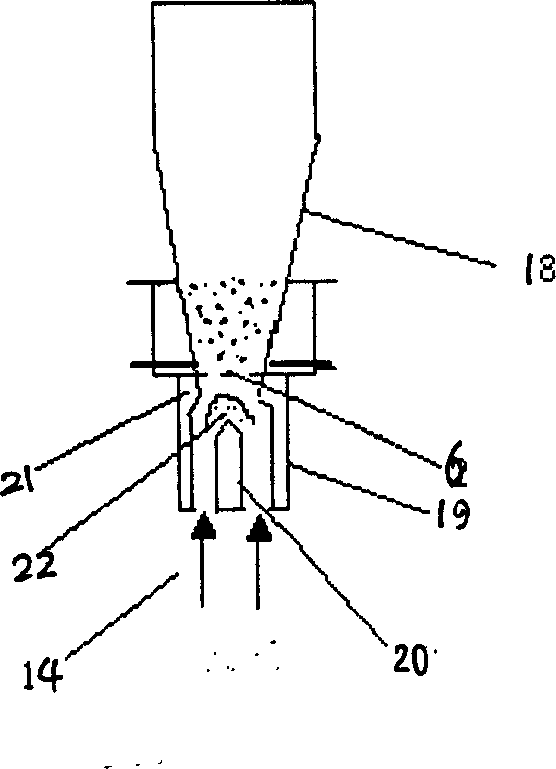

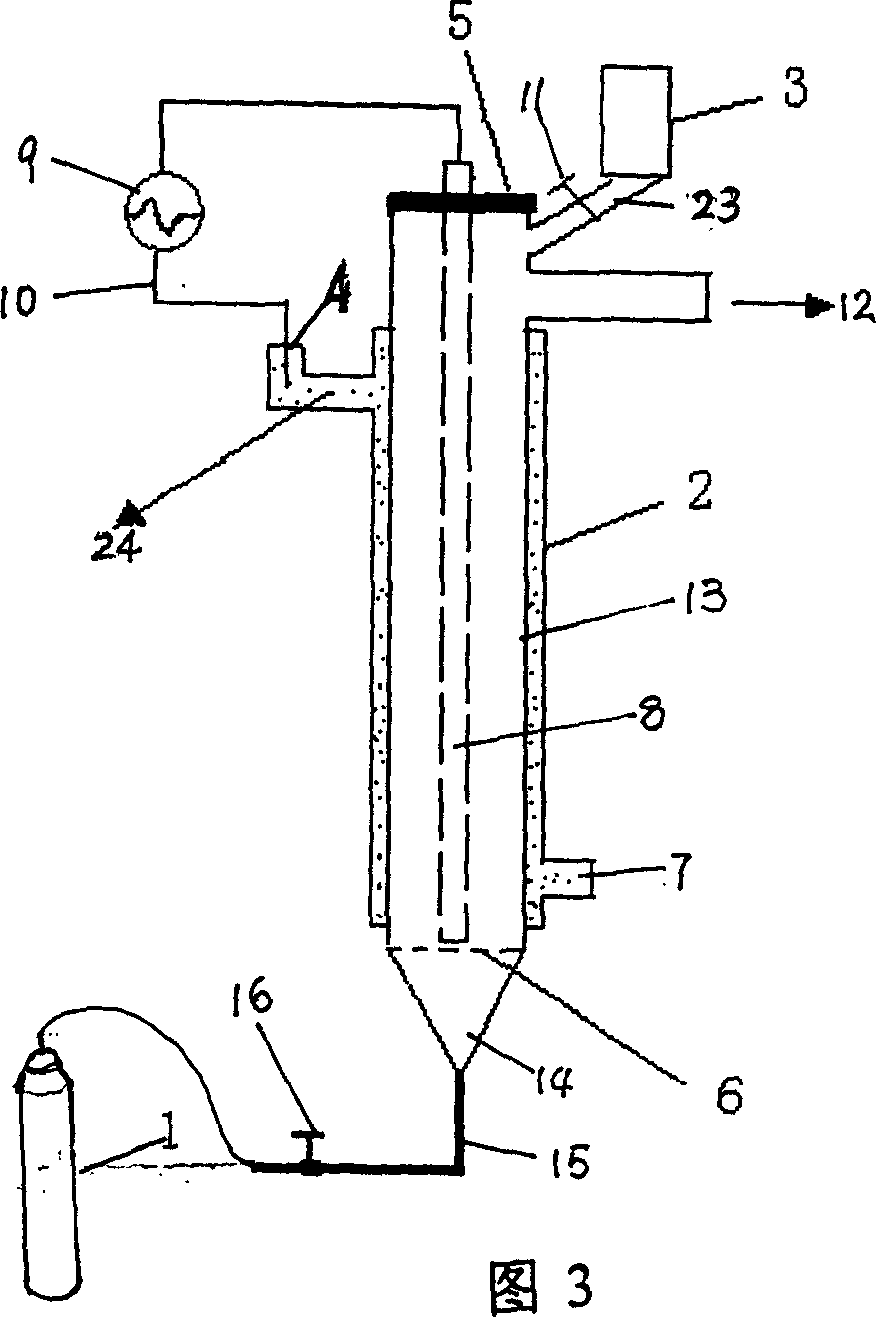

[0062] 1. For example, use Figure 3 to realize the modification of the hydrophilic properties of calcium carbonate powder materials: calcium carbonate powder is a material with very good hydrophilic properties. To make it into a non-hydrophilic material, it only needs to be coated on the surface of the powder A layer of low surface energy material is sufficient.

[0063] 1. First pass ordinary tap water into the hollow shell of the outer electrode of the plasma fluidized bed, and insert one pole of the high-voltage AC power supply into the conductive liquid for fixed connection; or directly connect the metal outer electrode to one pole of the high-voltage AC power supply connect;

[0064] 2. Put the gas distributor with a pore size of 5 microns into the bottom of the fluidized bed and install it;

[0065] 3. add the calcium carbonate powder that diameter is about 5 microns in funnel 3 again, then open valve and this powder material is delivered the calcium carbonate powder of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com