Preparation method of knitted Roman cloth

A tissue and needle cylinder technology, which is applied in the field of knitted Roman fabric preparation, can solve the problems of anti-pilling, shrinkage and poor stability, and achieve good anti-pilling performance, appropriate grammage, and clear cloth pattern. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

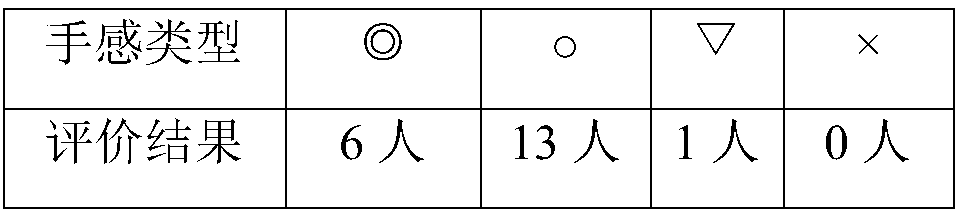

Examples

Embodiment 1

[0026] The present embodiment provides a kind of preparation method of knitted Roman cloth, comprising:

[0027] The raw materials are all cotton strong twisted 40s combed yarn (Shandong Hongjie Company), Z twist, S twist, twist 1750T.P.M, 2075 polyester-coated ammonia-coated yarn (Ningbo Dewei Company). The loom is the I3P284 model produced by Delo, Germany, with a specification of 34"*24G*2976N, and the number of yarn feeding paths is 96F.

[0028] Weaving process:

[0029] Yarn arrangement: the first and second knitting double Rowan weave, use 40s combed strong twist yarn (Z twist), the third knitting on the dial (the lower needle cylinder is not knitting), use 2075 polyester wheel to cover the yarn, the third knitting Four-way lower cylinder knitting (the upper needle does not knit), use 40s combed strong twist yarn (S twist), and four-way form a complete Roman cloth weave.

[0030] Dyeing and finishing process:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com