Aubergine liquid disperse dye as well as preparation method and application of dye

A liquid disperse dye, fuchsia technology, applied in the printing and dyeing of polyester fabrics, fuchsia liquid disperse dye and its preparation field, can solve the problems of blue spots, increased chroma of waste water, low purple-red vividness, etc. Process adaptability, good dyeing levelness, uniform dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

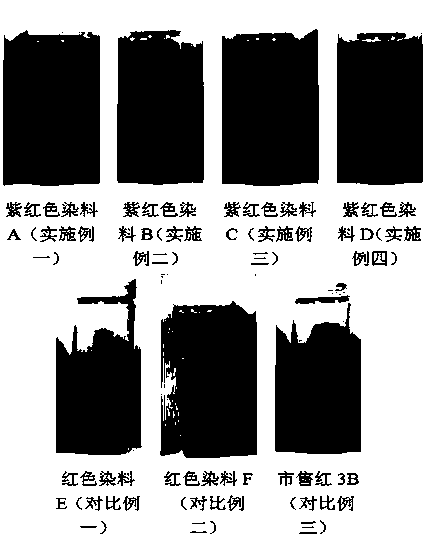

Embodiment 1

[0045] Mix 10.0g of 1-amino-4-hydroxy-2-phenoxy-9,10-anthraquinone, 1.5g of dispersant CNF, 2.0g of 1815, 0.2g of sodium hydroxide and 75.0g of water in percentage by mass, and grind thoroughly. Then add 0.2g of ethanol, 0.6g of sodium polyacrylate, 4.5g of water-soluble polyester, 0.3g of water-soluble polyether and 5.7g of water, and stir thoroughly to obtain a liquid purple-red disperse dye A.

[0046] In the intermittent high-temperature dyeing machine, add 100Kg of polyester fabric (adjust the pH value of the solution to 10.0), 4Kg of liquid purple-red disperse dye A and 800Kg of water, raise the temperature to 120°C, and keep it at this temperature for 30 minutes. After dyeing, use 50 ℃ hot water washing, made bright purple polyester fabric.

Embodiment 2

[0048] Mix 20.0g of 1-amino-4hydroxy-2-phenoxy-9,10-anthraquinone, 3.8g of dispersant CNF, 2.0g of 1815, 0.5g of sodium hydroxide and 65.0g of water in percentage by mass, and grind thoroughly, Then add 0.3g of ethanol, 0.3g of sodium polyacrylate, 5.0g of water-soluble polyester, 0.4g of water-soluble polyether and 2.7g of water, and stir thoroughly to obtain liquid purple-red disperse dye B.

[0049] In the intermittent high-temperature dyeing machine, add 100Kg of polyester fabric (adjust the pH value of the solution to 9.0), 2Kg of liquid purple-red disperse dye B and 800Kg of water, raise the temperature to 120 ° C, and keep it at this temperature for 30 minutes. After dyeing, use 50 ℃ hot water washing, made bright purple polyester fabric.

Embodiment 3

[0051] Mix 10.0g of 1-amino-4-hydroxy-2-phenoxy-9,10-anthraquinone, 3.8g of dispersant CNF, 1.0g of 1815, 0.5g of borax and 75.0g of water in percentage by mass, grind thoroughly, and then add 0.3g of ethanol, 0.3g of sodium polyacrylate, 5.0g of water-soluble polyester, 0.4g of water-soluble polyether and 3.7g of water were thoroughly stirred to obtain liquid purple-red disperse dye C.

[0052] In the intermittent high-temperature dyeing machine, add 100Kg of polyester fabric (adjust the pH value of the solution to 8.0), 4Kg of liquid purple-red disperse dye C and 800Kg of water, raise the temperature to 135 ° C, and keep it at this temperature for 30 minutes. After dyeing, use 50 ℃ hot water washing, made bright purple polyester fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com