Bacillus natto activation solution and preparation method and application thereof

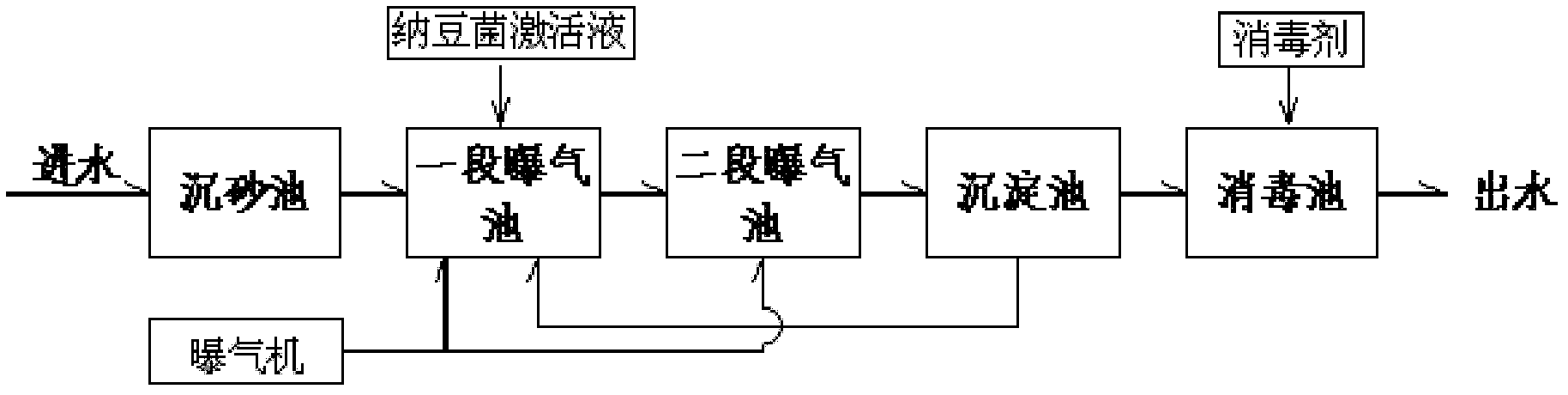

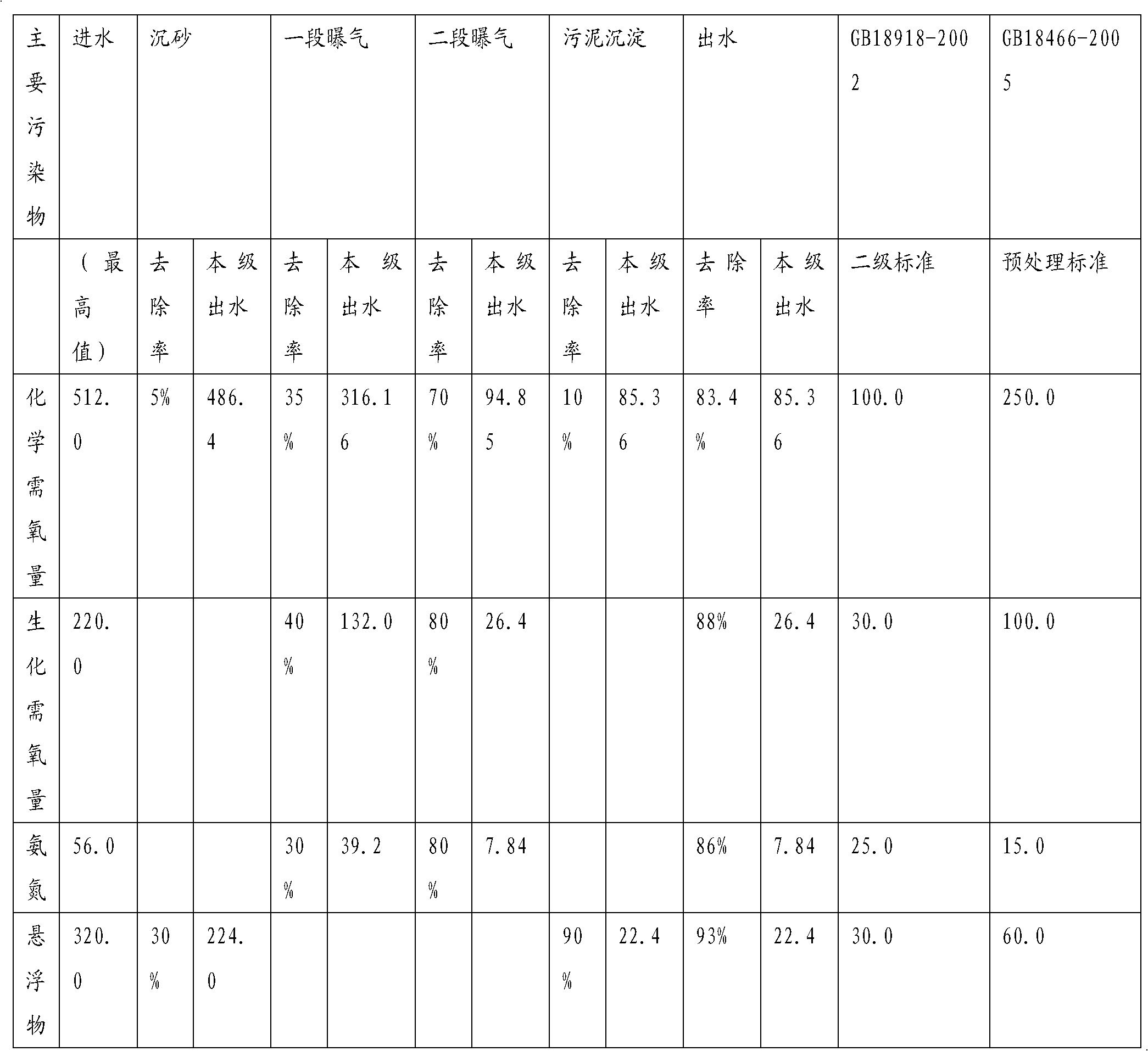

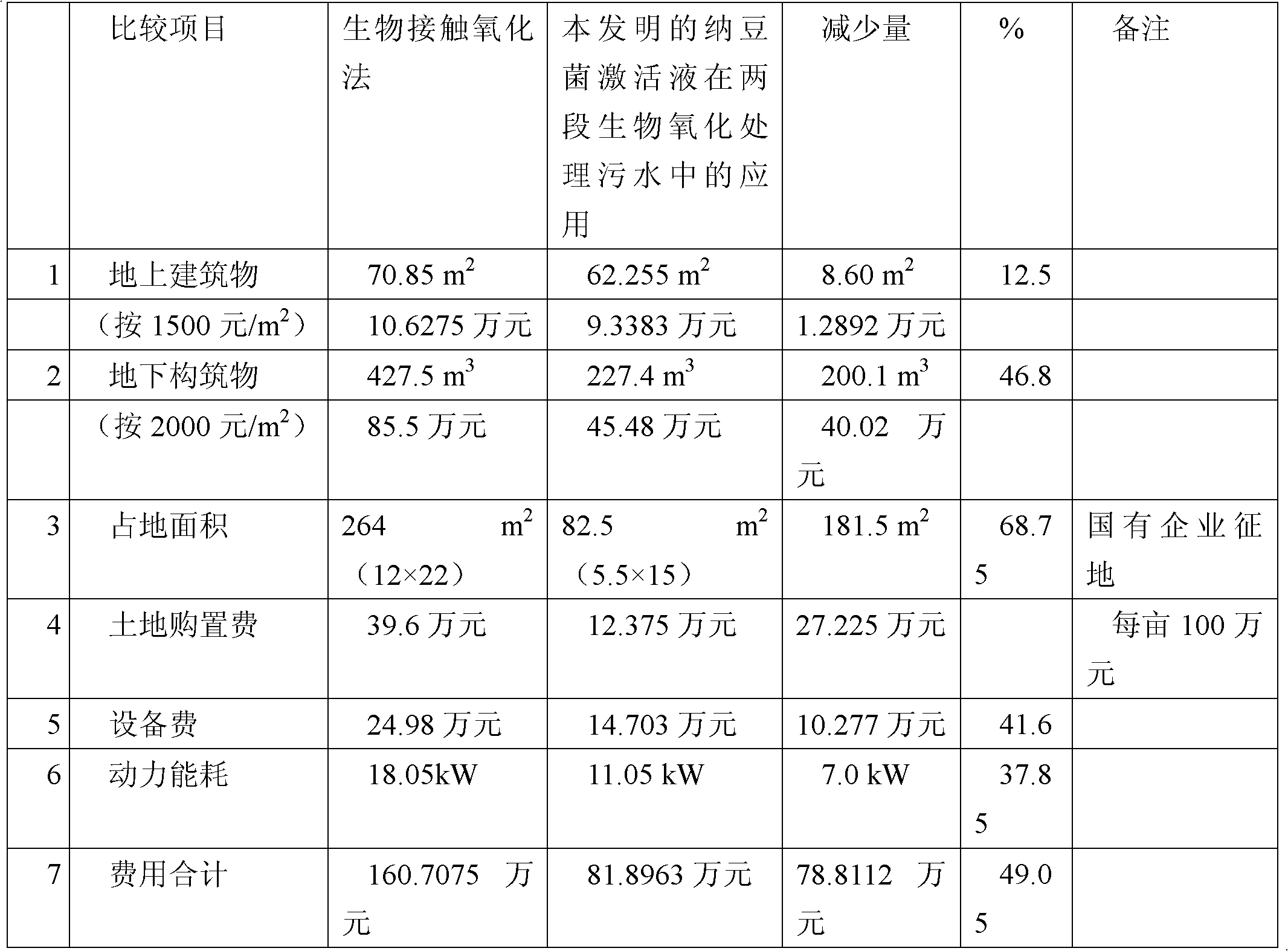

A technology of natto bacteria and aeration tank, which is applied in chemical instruments and methods, bacteria, water/sludge/sewage treatment, etc., can solve the problems of large area of equipment, secondary environmental pollution, and low decomposition ability. , to achieve the effect of small footprint, low equipment power consumption, and short start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A kind of bacillus natto activating liquid is made by following method:

[0055]Put 1 part of Bacillus natto dry powder into 1000 parts of pure water in parts by mass, add 0.008 part of egg white, 0.020 part of honey, and aerate for 3 hours according to the ratio of air-water ratio of 1:1. The Bacillus natto used in this example is a "microbial sewage treatment agent" produced and sold by Zhongshan Natto Microbial Products Co., Ltd.

Embodiment 2

[0057] A kind of bacillus natto activating liquid is made by following method:

[0058] Put 0.5 part of Bacillus natto dry powder into 1000 parts of purified water in parts by mass, add 0.01 part of duck egg white, 0.025 part of honey, and aerate for 4 hours at an air-to-water ratio of 1:1.

Embodiment 3

[0060] A natto activating solution is characterized in that it is made by the following method:

[0061] Put 0.6 part of Bacillus natto dry powder into 1000 parts of purified water in parts by mass, add 0.009 part of goose egg white, 0.025 part of honey, and aerate for 3 hours at an air-to-water ratio of 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com