Heavy metal ion complexing agent, preparation method and applications thereof

A technology of heavy metal ions and complexing agents, used in chemical instruments and methods, water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. Simple storage and use, low production cost, easy precipitation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

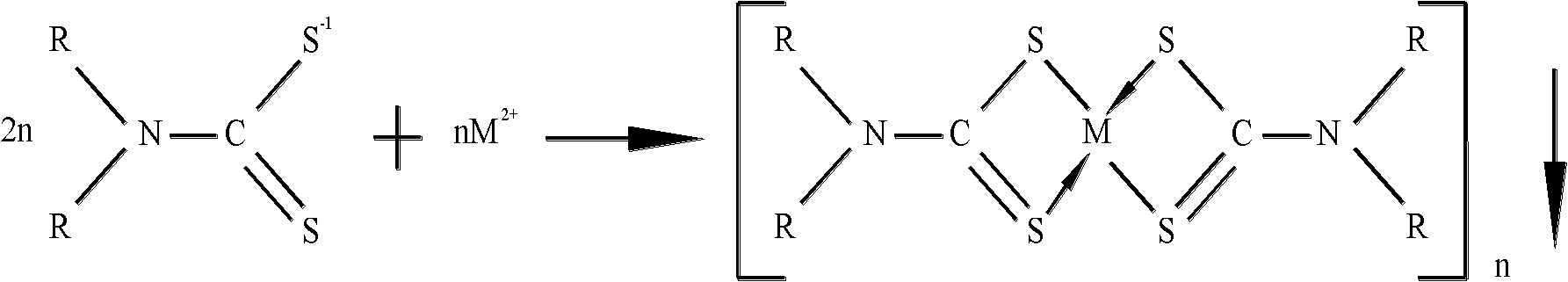

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The required production raw materials of the heavy metal ion complexing agent of preparation 1Kg: triethylenetetramine 100g, accounts for 10% of total amount; Sodium hydroxide 200g, accounts for 20% of total amount; Epichlorohydrin 50g, accounts for 5% of total amount ; CS 2 250g, accounting for 25% of the total amount; 400g of deionized water, accounting for 40% of the total amount.

[0050] In the preparation process, 200g sodium hydroxide is dissolved in 400g deionized water to obtain sodium hydroxide solution, and the aforementioned lye of 1 / 3 of the total volume is placed in a three-necked flask with a stirrer and a reflux condenser. Place in a water bath at 28°C and stir at a stirring speed of 800 rpm. At the same time, 100 g of triethylenetetramine was slowly added under stirring conditions, and then 50 g of epichlorohydrin was slowly added dropwise at a rate of 4% of the total mass per minute. After the chlorinated alkanes were added, the temperature was raise...

Embodiment 2

[0053] The required production raw materials of the heavy metal ion complexing agent of preparation 1Kg: ethylenediamine 40g, accounts for 4% of total amount; Potassium hydroxide 100g, accounts for 10% of total amount; Dichloroethane 20g, accounts for 2% of total amount; CS 2 80g, accounting for 8% of the total amount; 20g of methanol, accounting for 2% of the total amount; 740g of deionized water, accounting for 74% of the total amount.

[0054] In the preparation process, 100g of potassium hydroxide is dissolved in 740g of deionized water to obtain sodium hydroxide solution, and 1 / 4 of the total volume of lye is placed in a three-necked flask with a stirrer and a reflux condenser. Stir in a water bath at 20°C at a stirring speed of 500 rpm. At the same time, slowly add 40g of ethylenediamine under the condition of stirring, and then slowly dropwise add 20g of dichloroethane, and the dropping rate per minute is 2% of the total amount. After the chlorinated alkanes are added,...

Embodiment 3

[0057] The required production raw materials of the heavy metal ion complexing agent of preparation 1Kg: diethylenetriamine 80g, account for 8% of total amount; Sodium hydroxide 150g, account for 15% of total amount; Dichloropropane 40g, account for 4% of total amount; CS 2 100g, accounting for 10% of the total amount; 50g of ethanol, accounting for 5% of the total amount, and 560g of deionized water, accounting for 56% of the total amount. In the preparation process, 150g of sodium hydroxide is dissolved in 560g of deionized water to obtain sodium hydroxide solution, and 1 / 2 of the total volume of lye is placed in a three-necked flask with a stirrer and a reflux condenser. Stir in a water bath at 25°C at a stirring speed of 800 rpm. At the same time, slowly add 80g of diethylenetriamine under the condition of stirring, then slowly add 40g of dichloropropane dropwise, the rate of dropping per minute is 3% of the total amount, after the chlorinated alkanes are added, heat up t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com