Shortened wet steaming pad-dyeing technology of all-cotton fabric vat dye

A cotton fabric, short wet steaming technology, applied in the field of printing and dyeing, can solve the problems of whitening of the bottom of cotton fabrics, poor stability of dye dispersions, and high requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

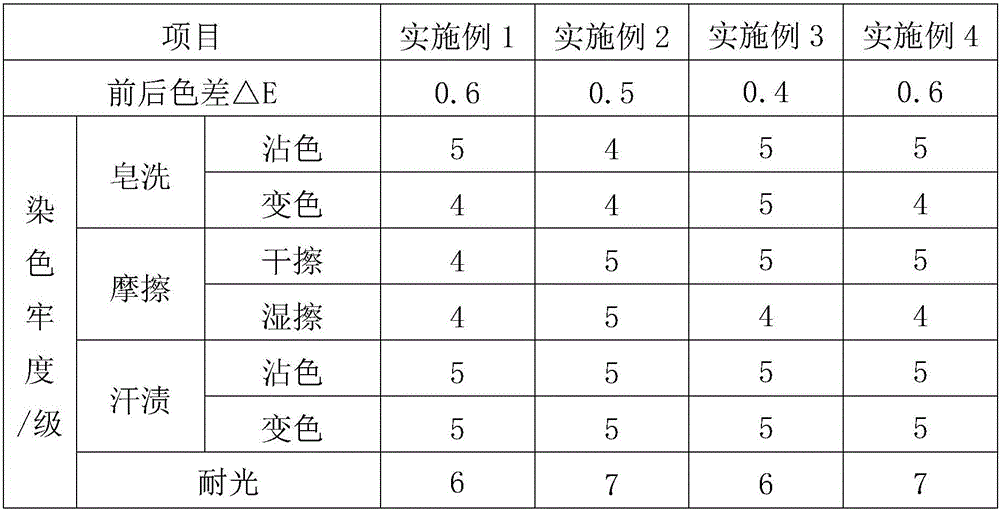

Examples

Embodiment 1

[0022] In the present embodiment, a short-wet steam pad dyeing process of cotton fabric vat dyes comprises the following processes:

[0023] S1, padding dyeing solution, according to the bath ratio of 1:5, the cotton fabric is padding dyeing solution, the padding temperature is 40 ° C, the padding rate is 85%, the formula of the dyeing solution includes: dyestuff 25g / L , dispersant 3.0g / L, penetrant T2.0g / L; the formula of described dispersant comprises by weight: 12 parts of sodium lignosulfonate, 10 parts of polyvinylpyrrolidone K-30, nanometer dioxide 3 parts of silicon, 3 parts of sodium sulfite, 10 parts of polyacryl alcohol, 10 parts of Pingpingjiao, 30 parts of water;

[0024] S2, add auxiliary agent, utilize high liquid supply device to supply auxiliary agent, the liquid carrying rate of auxiliary agent on described cotton fabric is 100%, the formula of described auxiliary agent comprises: reducing agent 5g / L, caustic soda 60g / L, chelate dispersant 1g / L; the preparati...

Embodiment 2

[0030] In the present embodiment, a short-wet steam pad dyeing process of cotton fabric vat dyes comprises the following processes:

[0031] S1, padding dyeing solution, according to the bath ratio of 1:10, the cotton fabric is padding dyeing solution, the padding temperature is 20 ℃, and the excess rate is 95%. The formula of the dyeing solution includes: dyestuff 15g / L , dispersant 9.0g / L, penetrant T1.0g / L; The formula of described dispersant comprises by weight: 18 parts of sodium lignosulfonate, 4 parts of polyvinylpyrrolidone K-30, nanometer dioxide 5 parts of silicon, 1 part of sodium sulfite, 20 parts of polyacryl alcohol, 8 parts of Pingping O, 60 parts of water;

[0032] S2, add auxiliary agent, utilize high liquid supply device to supply auxiliary agent, the liquid carrying rate of auxiliary agent on described cotton fabric is 90%, the formula of described auxiliary agent comprises: reducing agent 20g / L, caustic soda 20g / L, chelate dispersant 1.5g / L; the preparatio...

Embodiment 3

[0038] In the present embodiment, a short-wet steam pad dyeing process of cotton fabric vat dyes comprises the following processes:

[0039] S1, padding dyeing solution, according to the bath ratio of 1:7, the cotton fabric is padding dyeing solution, the padding temperature is 30°C, and the padding rate is 90%. The formula of the dyeing solution includes: dye 20g / L , dispersant 6.0g / L, penetrant T1.5g / L; The formula of described dispersant comprises by weight: 15 parts of sodium lignosulfonate, 7 parts of polyvinylpyrrolidone K-30, nanometer dioxide 4 parts of silicon, 2 parts of sodium sulfite, 15 parts of polyacryl alcohol, 9 parts of Pingpingjiao, 45 parts of water;

[0040] S2, add auxiliary agent, utilize high liquid supply device to supply auxiliary agent, the liquid carrying rate of auxiliary agent on described cotton fabric is 95%, the formula of described auxiliary agent comprises: reducing agent 12g / L, caustic soda 40g / L, chelate dispersant 1.2g / L; the preparation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com