Environment-friendly low-toxicity gold ore ore-dressing additive and preparation method thereof

A technology for additives and gold ore, which is applied in the field of environmental protection and low-toxicity gold ore beneficiation additives and its preparation, can solve the problems of resource loss, low recovery rate, waste, etc., and achieves the effect of improving gold recovery rate and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

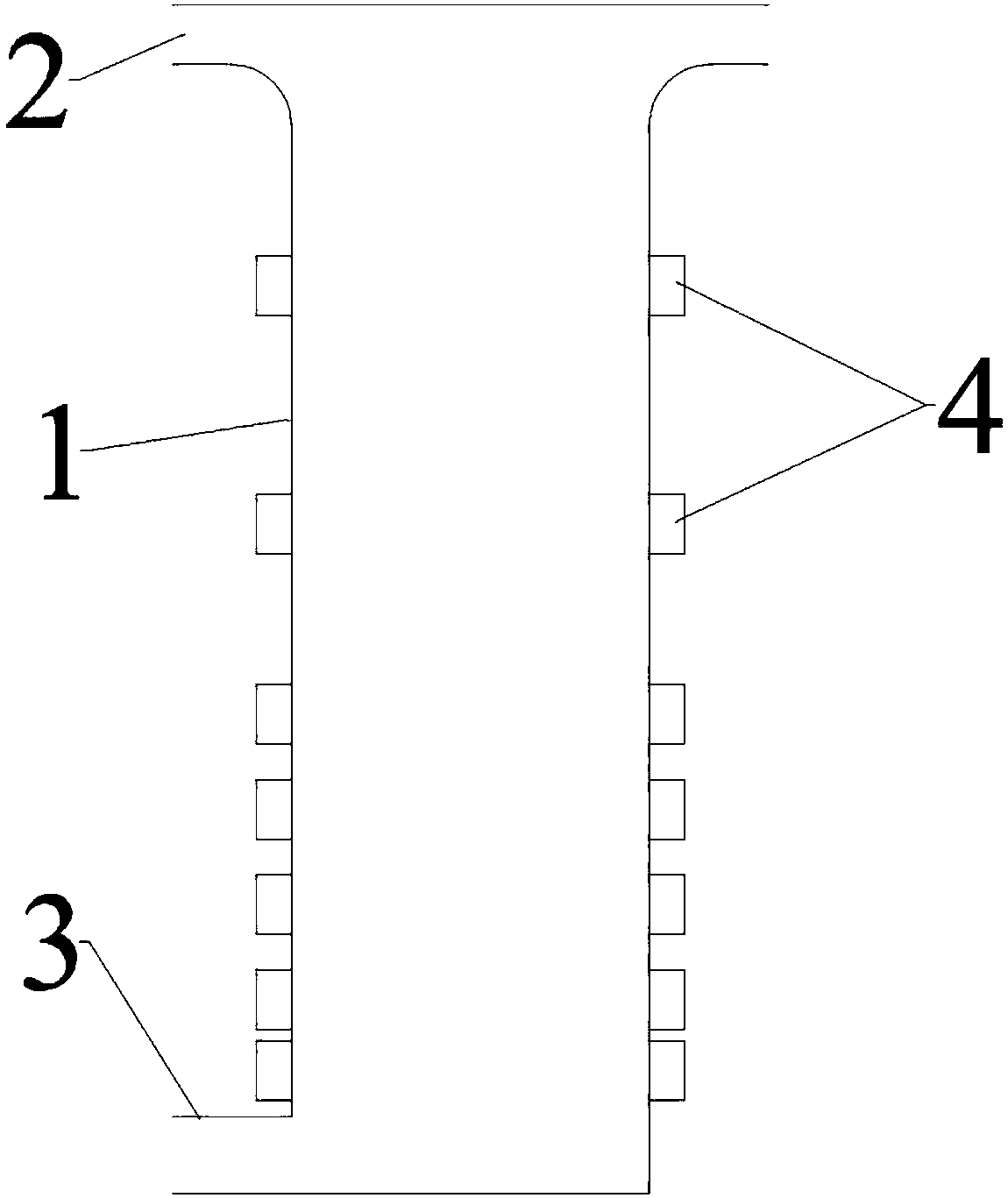

Image

Examples

Embodiment 1

[0025] An environment-friendly and low-toxicity gold ore dressing additive consists of the following raw materials in parts by weight:

[0026] Potassium ferrocyanide 20 parts, potassium iodide 8 parts, potassium bromide 5 parts, potassium sulfide 5 parts, sodium percarbonate 40 parts, polyacrylamide 5 parts, urea 10 parts, sodium hydroxide 5 parts, sodium tripolyphosphate 10 parts 10 parts, 10 parts of ethoxylated alkyl sodium sulfate, 10 parts of magnetite powder.

[0027] The preparation method of environment-friendly and low-toxicity gold ore dressing additive comprises:

[0028] Step 1. Take the magnet powder in the above parts by weight, heat it to a molten state, add the potassium iodide, potassium bromide and potassium sulfide in the above parts by weight, mix well, and keep it for 2 hours, then cool to 900 °C at a rate of 10 °C / hour Cool down to 600°C, then raise the temperature to 900°C at a rate of 15°C / hour, repeat the operation of cooling at a rate of 10°C / hour a...

Embodiment 2

[0036] An environment-friendly and low-toxicity gold ore dressing additive consists of the following raw materials in parts by weight:

[0037] Potassium ferrocyanide 30 parts, potassium iodide 10 parts, potassium bromide 8 parts, potassium sulfide 8 parts, sodium percarbonate 50 parts, polyacrylamide 10 parts, urea 15 parts, sodium hydroxide 10 parts, sodium tripolyphosphate 15 parts 15 parts, ethoxylated alkyl sodium sulfate 15 parts, magnetite powder 15 parts.

[0038] The preparation method of environment-friendly and low-toxicity gold ore dressing additive comprises:

[0039] Step 1. Take the magnet powder in the above parts by weight, heat it to a molten state, add the potassium iodide, potassium bromide and potassium sulfide in the above parts by weight, mix evenly, and keep it for 3 hours, cool to 900 °C at a rate of 10 °C / hour Cool down to 600°C, then raise the temperature to 900°C at a rate of 15°C / hour, repeat the operation of cooling at a rate of 10°C / hour and hea...

Embodiment 3

[0047] An environment-friendly and low-toxicity gold ore dressing additive consists of the following raw materials in parts by weight:

[0048] Potassium ferrocyanide 25 parts, potassium iodide 9 parts, potassium bromide 6 parts, potassium sulfide 6 parts, sodium percarbonate 45 parts, polyacrylamide 8 parts, urea 12 parts, sodium hydroxide 8 parts, sodium tripolyphosphate 12 parts 12 parts, ethoxylated alkyl sodium sulfate 12 parts, magnetite powder 12 parts.

[0049] The preparation method of environment-friendly and low-toxicity gold ore dressing additive comprises:

[0050]Step 1. Take the magnet powder in the above parts by weight, heat it to a molten state, add the potassium iodide, potassium bromide and potassium sulfide in the above parts by weight, mix well, and keep it for 2 hours, then cool to 900 °C at a rate of 10 °C / hour Cool down to 600°C, then raise the temperature to 900°C at a rate of 15°C / hour, repeat the operation of cooling at a rate of 10°C / hour and heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com