3D printing composite material containing organic fluorescent dye and application thereof

A fluorescent dye and 3D printing technology, applied in the field of 3D printing, can solve the problems of design and installation difficulties, limited application range of PLA materials, etc., and achieve the effect of easy operation, increased artistic expression ability, and uniform dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

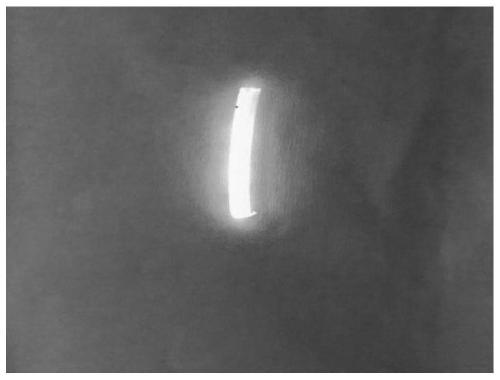

[0024] Example 1 Dissolve 10 mg of 4,7-dithienylbenzothiadiazole and orange fluorescent material in 50 ml of dichloromethane solvent and mix well to obtain 4,7-dithienylbenzothiadiazole orange For organic fluorescent dyes, apply the solution to PLA filaments. Be careful to keep the PLA filaments separate from each other to avoid sticking together after application. PLA filaments containing orange organic fluorescent dyes are available (see figure 1 ).

Embodiment 2

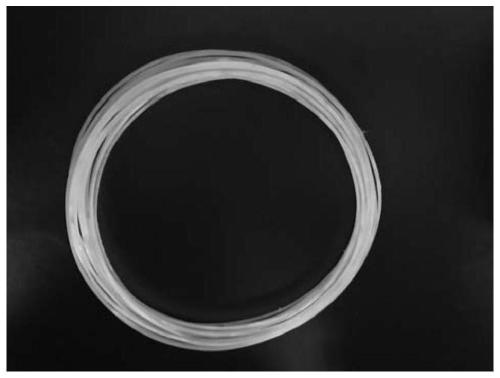

[0026] Dissolve 10 mg of 4,7-bithienylbenzothiadiazole, an orange fluorescent material in 50 ml of dichloromethane solvent, and mix well to obtain 4,7-bithienylbenzothiadiazole orange organic fluorescent dye. Evenly soak the PLA wire into a large beaker filled with organic fluorescent dyes. After soaking completely for 10S, the PLA wires are taken out, and the PLA wires are separated from each other to avoid bonding to each other, and the PLA wires containing orange organic fluorescent dyes are obtained (see figure 2 ).

Embodiment 3

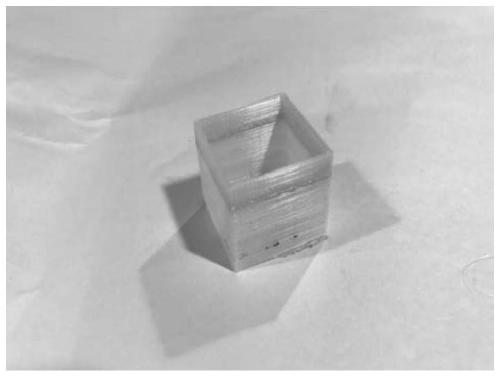

[0028] Dissolve 10mg of 4,7-dithienylbenzothiadiazole and orange fluorescent material in 50 ml of dichloromethane solvent, and mix well to obtain 4,7-dithienylbenzothiadiazole orange organic fluorescent dye. The solution is applied to the PLA wire to obtain the PLA wire coated with the orange organic fluorescent dye. A hollow cube three-dimensional figure with dimensions of 4.2cm in length, 4.2cm in width, and 4cm in height, with a wall thickness of 0.1cm will be designed by computer, processed in layers and sliced, and imported into a 3D printer. The printing consumables use PLA filament coated with orange organic fluorescent dye. Place the hollow cube to be printed on the 3D printer station, and it is controlled by the computer for 3D printing. A PLA hollow cube structure stained with an orange organic fluorescent dye was obtained (see image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com