Quantum dot/polyaryletherketone nanometer composite material and preparing method thereof

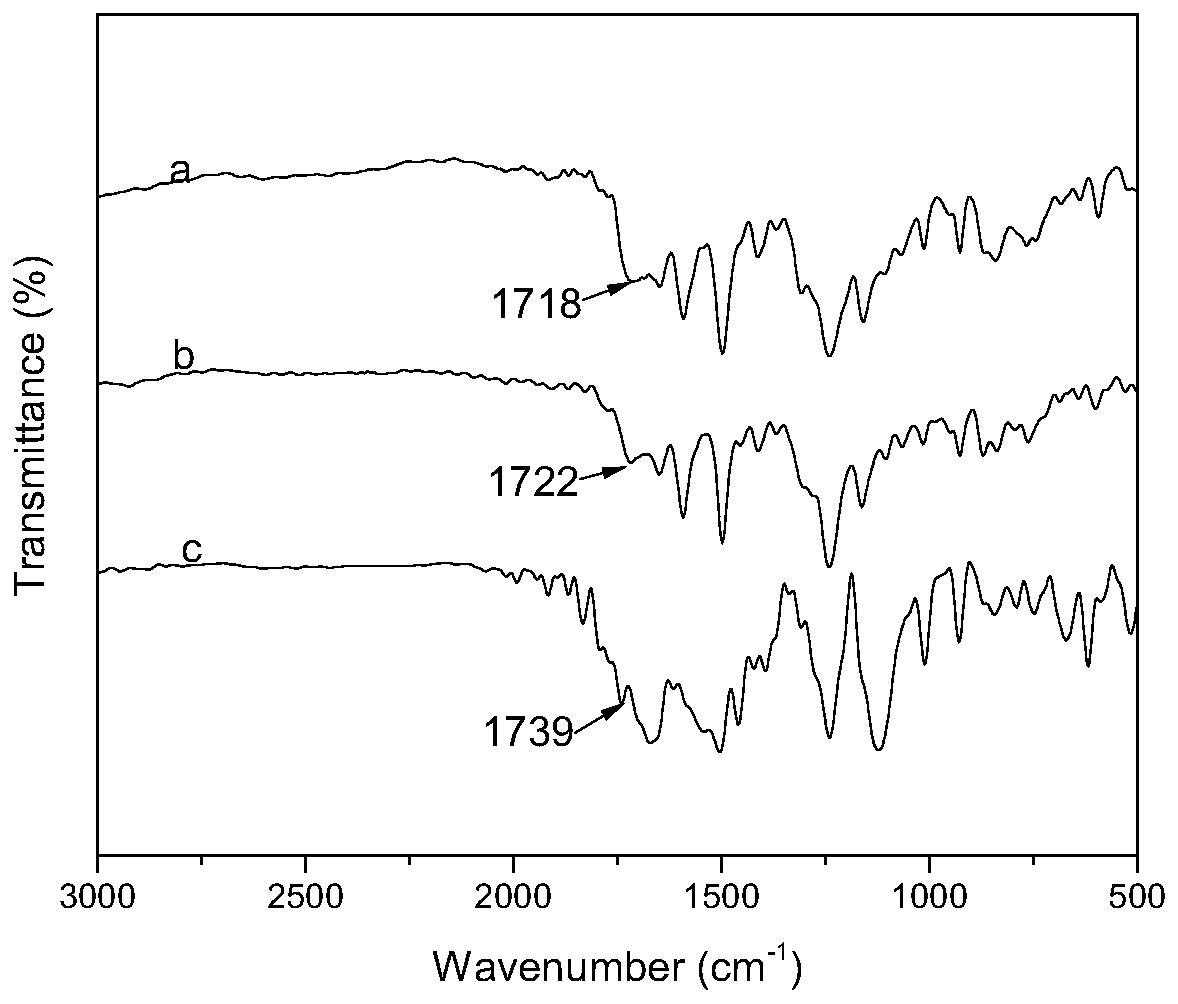

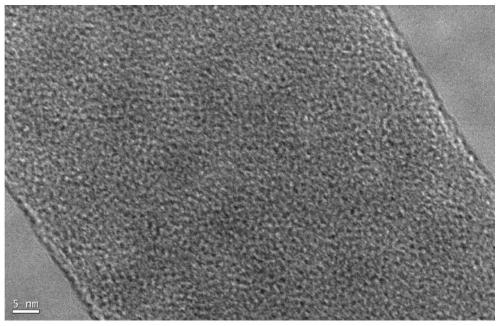

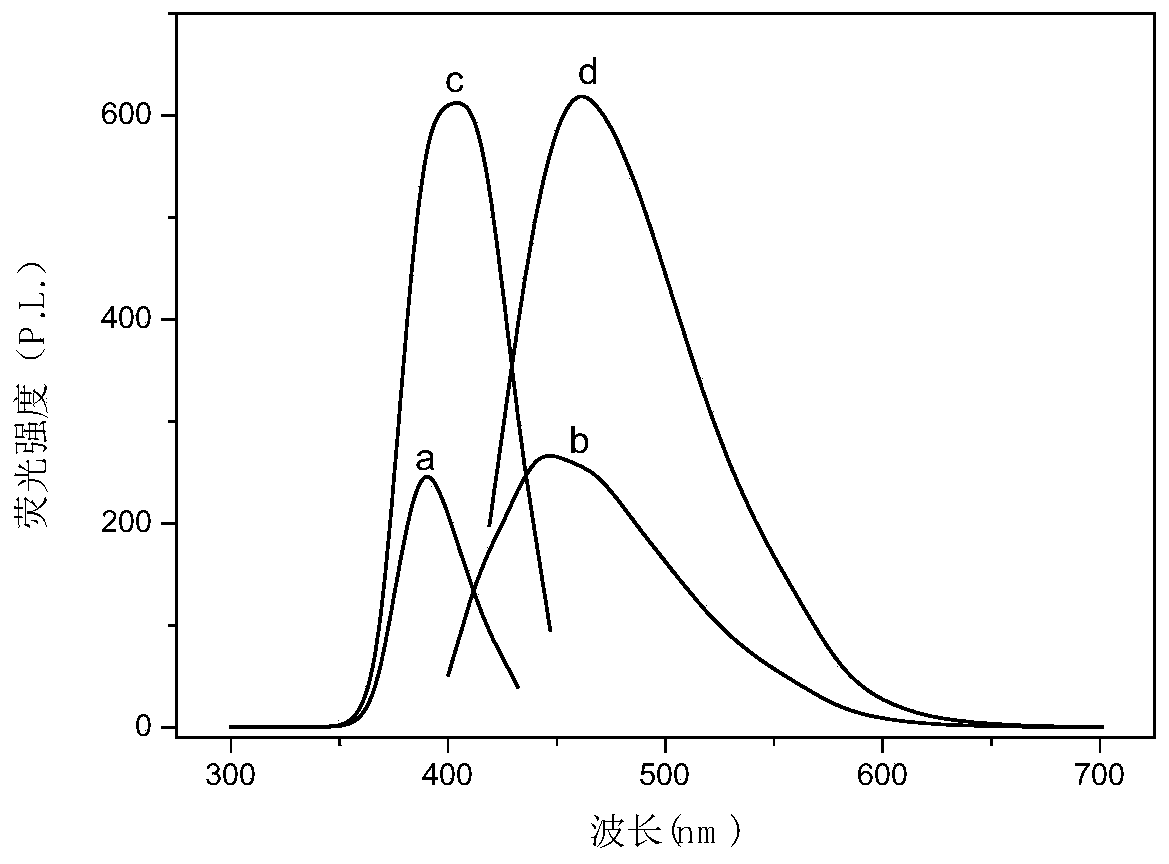

A nanocomposite material, polyaryletherketone technology, applied in the direction of conjugated synthetic polymer rayon, rayon manufacturing, filament/wire molding, etc., can solve the small size of CdS quantum dots, easy to agglomerate, and limit applications etc. to achieve excellent thermal stability, uniform fiber diameter distribution, and enhanced luminous performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1: Add 4.3246g (13.5mmol) phenolphthalein monomer and 3.5429g (15mmol) 2,4' , 6-trifluoro-benzophenone, followed by the addition of 0.9781 g (4.725 mmol) of anhydrous potassium carbonate and 1.5026 g (9.45 mmol) of anhydrous sodium carbonate.

[0026] Step 2: Add 18mL solvent sulfolane and 15mL water-carrying agent toluene into the system, heat to toluene reflux (130°C, corresponding to the salt-forming step described in the summary of the invention) under nitrogen gas under agitation, and reflux for 3 hours to ensure the removal of the system After the water in the solution, toluene was released.

[0027] The third step: using the step-by-step heating method, the temperature of the system was raised to 160°C, 180°C, 200°C, and 220°C for 2 hours each. After the reaction is completed, discharge the mixture solution into hydrochloric acid aqueous solution, pulverize it with a powder machine, and wash the material several times with boiling distilled water and ethano...

Embodiment 2

[0032] Step 1: Add 4.0827g (12.74mmol) phenolphthalein monomer and 2.7819g (12.74mmol) 4,4-difluorobenzophenone monomer and 3.1659g (22.93mmol) anhydrous potassium carbonate in a 100mL three-necked flask .

[0033] Step 2: Add 18 mL of dimethyl sulfoxide and 13 mL of toluene into the three-necked flask. Install a nitrogen vent on the three-necked flask, a stirring paddle, and a water device, and heat it to toluene reflux (145° C., the content of the invention to form a salt) under the condition of nitrogen, and release water and toluene after 3 hours.

[0034] The third step: raise the temperature of the reaction system to 180° C., and react for 4 hours. After the reaction is completed, the material is discharged into an aqueous solution of hydrochloric acid. The polymer was pulverized and washed three times with hot water and cold ethanol to remove solvents and small molecules. Vacuum drying at 90°C to obtain linear benzene carboxyl side group polyaryletherketone.

Embodiment 3

[0036] Add 7.7108g of N,N-dimethylformamide and 1.0479g of linear phenylcarboxy side group polyaryletherketone to the sample bottle, stir for 12h, pour into a 10mL syringe, install it on an electrospinning device, use aluminum foil as a receiving plate, and use a needle The distance from the receiving plate is 15cm, the injection speed is 1-2mL / h, and the voltage is 15-20kv. Drying the obtained fiber membrane at 80-100° C. for 24 hours under true conditions to obtain a linear phenylcarboxy side group polyaryletherketone fiber membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com