Preparation method of chitosan/gallnut tannin composite fibers

A technology of gallic tannin and composite fiber, which is applied in the chemical characteristics of fibers, wet spinning, rayon manufacturing, etc., can solve the problems of glutaraldehyde cross-linking agent being toxic, not environmentally friendly, and difficult to degrade polyvinyl alcohol. Good stability, improved water resistance stability, strong antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Adopt the following method to prepare chitosan gallnut tannin composite fiber, concrete steps:

[0068] Step 1: Prepare spinning solution

[0069] (1) Chitosan is dissolved in the acetic acid solution that mass concentration is 2%, and the mass concentration of described chitosan in solution is 4%, and dissolving temperature is 25 ℃, and mechanical stirring 7h;

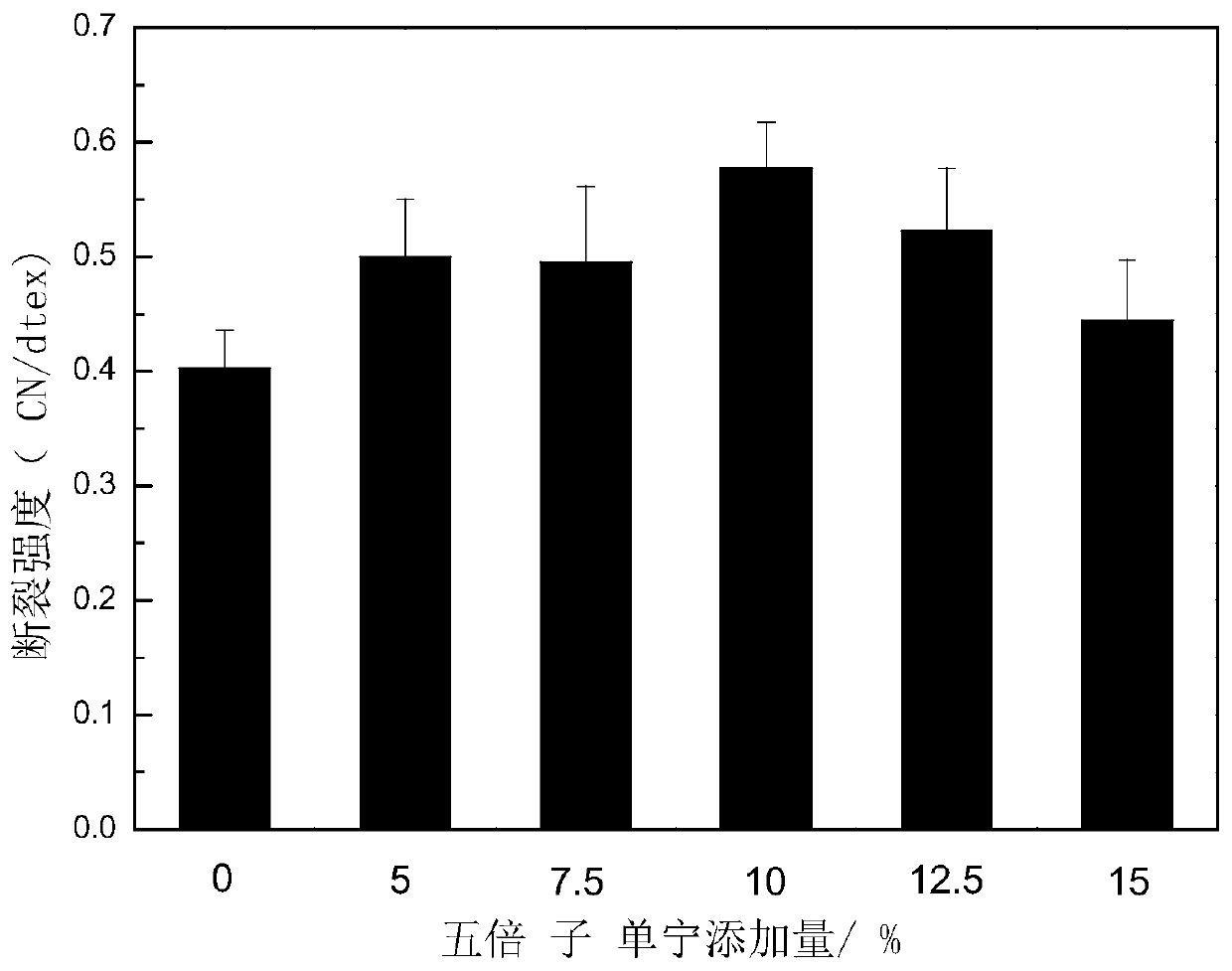

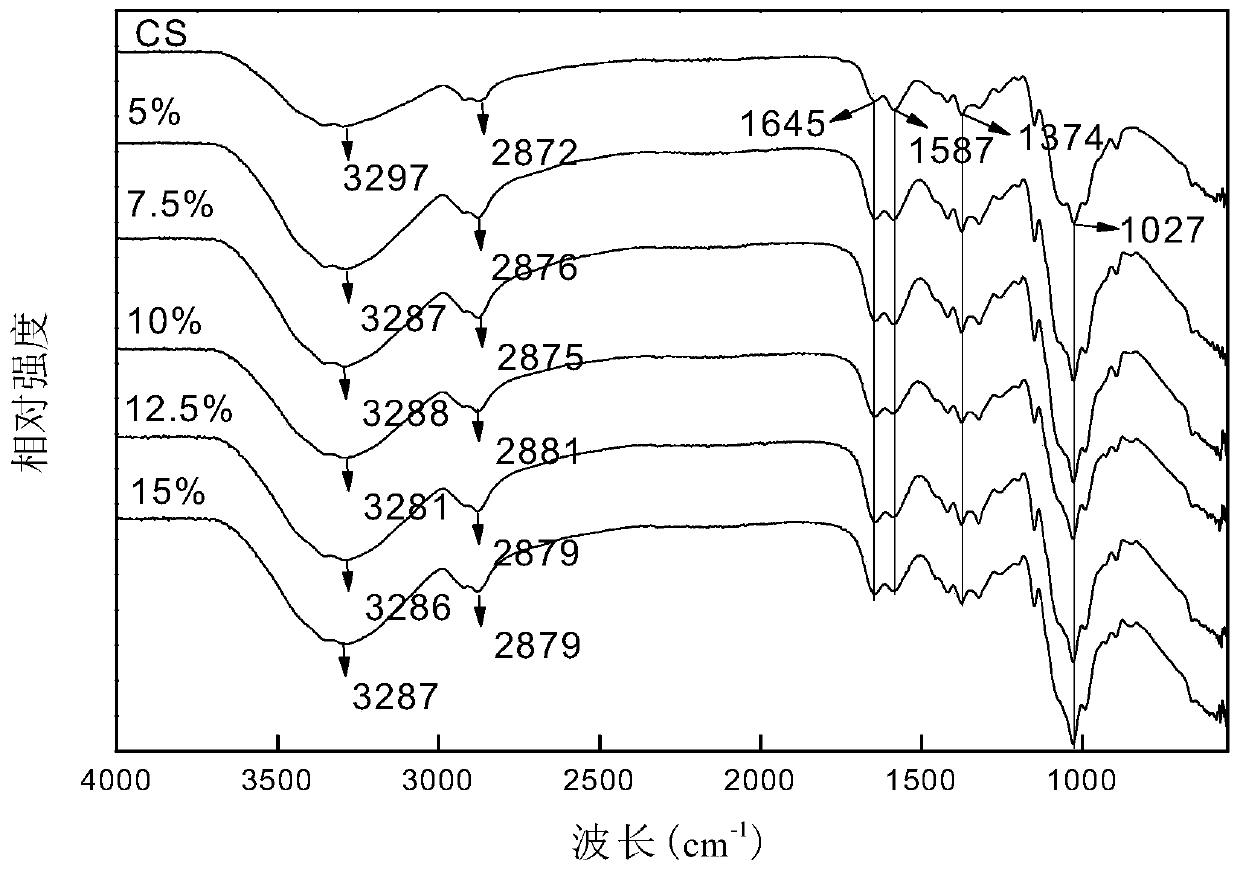

[0070] (2) Galla tannin is added in the chitosan acetic acid solution with respect to chitosan mass respectively in the consumption of 5%, 7.5%, 10%, 12.5%, 15%, mechanical stirring 28h under 25 ℃ of conditions, make Gallnut tannins are fully dissolved and mixed evenly with chitosan;

[0071] (3) Chitosan and Galla tannin mixed solution are subjected to ultrasonic treatment for 17min under ultrasonic conditions with a frequency of 20KHz to remove air bubbles in the solution to obtain spinning solution;

[0072] Step 2: Prepare coagulation bath

[0073] The preparation mass concentration is the NaOH aqueous s...

Embodiment 2

[0110] Adopt the following method to prepare chitosan gallnut tannin composite fiber, concrete steps:

[0111] Step 1: Prepare spinning solution

[0112] (1) Chitosan is dissolved in the acetic acid solution that mass concentration is 2%, and the mass concentration of described chitosan in solution is 3%, and dissolution temperature is room temperature, and mechanical stirring 8h;

[0113] (2) gallnut tannin is added in the chitosan acetic acid solution with respect to the consumption of chitosan quality 10%, mechanically stirred 36h under room temperature, gallnut tannin is fully dissolved and mixed with chitosan;

[0114] (3) Chitosan and Galla tannin mixed solution are subjected to ultrasonic treatment for 15min under ultrasonic conditions with a frequency of 20KHz to remove air bubbles in the solution to obtain spinning solution;

[0115] Step 2: Prepare coagulation bath

[0116] The preparation mass concentration is the NaOH aqueous solution of 5%, and adds ethanol, and...

Embodiment 3

[0123] Adopt the following method to prepare chitosan gallnut tannin composite fiber, concrete steps:

[0124] Step 1: Prepare spinning solution

[0125] (1) Chitosan is dissolved in the acetic acid solution that mass concentration is 2%, and the mass concentration of described chitosan in solution is 5%, and dissolving temperature is 40 ℃, mechanical stirring 6h;

[0126] (2) Galla tannin is added to the chitosan acetic acid solution in an amount of 10% relative to the chitosan mass, mechanically stirred for 20 h at 40° C., so that galla tannin is fully dissolved and mixed evenly with chitosan;

[0127] (3) Chitosan, Galla gall tannin mixed solution is under the ultrasonic condition of frequency 20KHz, sonication 20min is to remove the air bubble in the solution, obtains the spinning solution;

[0128] Step 2: Prepare coagulation bath

[0129] The preparation mass concentration is the NaOH aqueous solution of 2%, and adds ethanol, and the ethanol consumption is 25% of the N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com