High-temperature-resistant optical cable and preparation method thereof

A high temperature resistant, optical cable technology, applied in coating, fiber mechanical structure, etc., can solve problems such as strong wind, easy deformation and bending of optical fiber, aging of optical cable surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

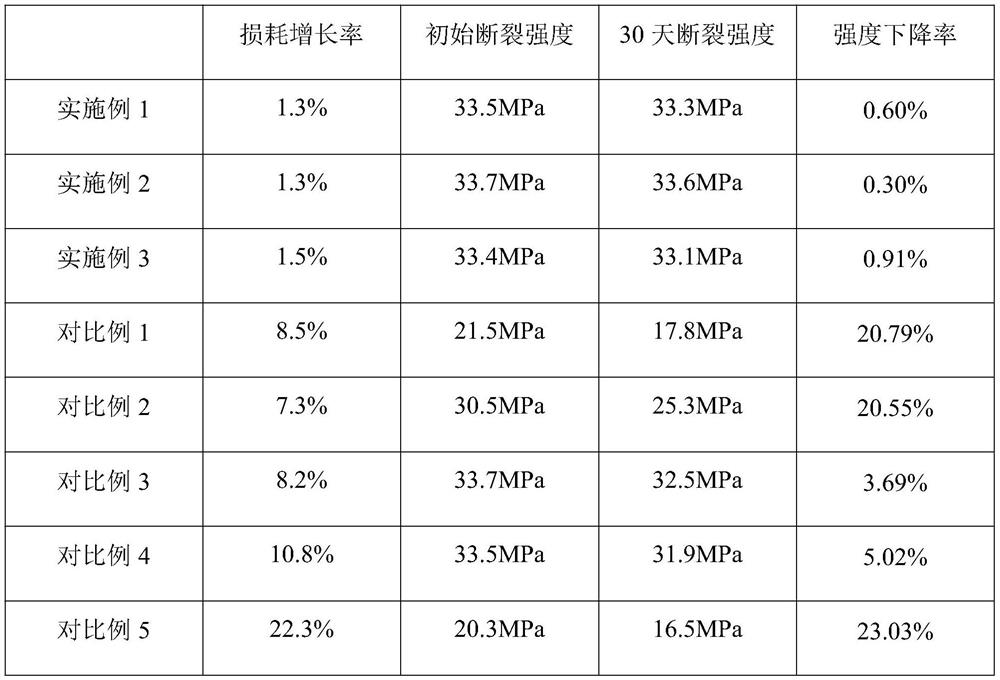

Examples

Embodiment 1

[0029] A high-temperature-resistant optical cable mainly includes, in parts by weight, 15 parts of core material, 5 parts of modified carbon nanotube mixed solution, 1 part of porous silicon dioxide and 1 part of fluorescent chelate.

[0030] A method for preparing a high-temperature-resistant optical cable, the method for preparing a high-temperature-resistant optical cable mainly includes the following preparation steps:

[0031] (1) Softening and embedding: heat the core material to 120°C for 5 minutes, and then add porous silica at 0.1g / cm 2 Lay flat and heat to 160°C, stop heating and roll the core material on the surface covered with porous silica at a speed of 30r / min for 5 laps to obtain a softened and embedded core material;

[0032] (2) Coating: Coat the modified carbon nanotube mixture on the softened and embedded core material with a coating thickness of 2 mm, let it stand for 6 hours at 100 ° C under a pressure of 10 MPa, and then immerse it in butyl ether to make...

Embodiment 2

[0043] A high-temperature-resistant optical cable mainly includes, in parts by weight, 13 parts of core material, 6 parts of modified carbon nanotube mixed solution, 2 parts of porous silicon dioxide and 2 parts of fluorescent chelate.

[0044] A method for preparing a high-temperature-resistant optical cable, the method for preparing a high-temperature-resistant optical cable mainly includes the following preparation steps:

[0045] (1) Softening and embedding: heat the core material to 1203°C for 4 minutes, and then add porous silica at 0.1g / cm 2 Lay flat and heat to 170°C, stop heating and roll the core material on the surface covered with porous silica at a speed of 40r / min for 4 circles to obtain a softened and embedded core material;

[0046] (2) Coating: Coat the modified carbon nanotube mixture on the softened and embedded core material with a coating thickness of 2-3mm, let it stand for 5 hours at 110°C under a pressure of 13MPa, and then immerse in butyl ether Cover...

Embodiment 3

[0057] A high-temperature-resistant optical cable mainly includes, in parts by weight, 10 parts of core material, 7 parts of modified carbon nanotube mixed solution, 3 parts of porous silicon dioxide and 3 parts of fluorescent chelate.

[0058] A method for preparing a high-temperature-resistant optical cable, the method for preparing a high-temperature-resistant optical cable mainly includes the following preparation steps:

[0059] (1) Softening and embedding: heat the core material to 125°C for 3 minutes, and then add porous silica at 0.1g / cm 2 Lay flat and heat to 180°C, stop heating and roll the core material on the surface covered with porous silica at a speed of 30r / min for 3 circles to obtain a softened and embedded core material;

[0060] (2) Coating: Coat the modified carbon nanotube mixture on the softened and embedded core material with a coating thickness of 3 mm, let it stand for 4 hours at 120 ° C under a pressure of 15 MPa, and then immerse it in butyl ether to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com