Dyeing method for improving disperse dye color fastness of polyester fabrics

A polyester fabric and disperse dye technology is applied in the field of polyester dyeing to achieve the effects of excellent dyeing fastness, favorable for popularization and application, good dyeing depth and dye utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

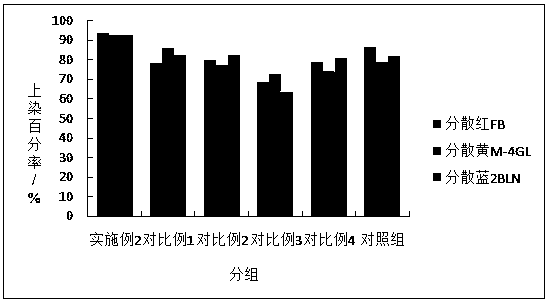

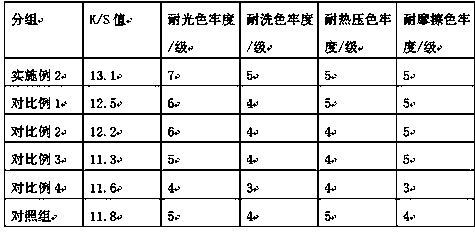

Examples

Embodiment 1

[0027] A kind of dyeing method that improves the disperse dye color fastness of polyester fabric, comprises the steps:

[0028] (1) Polyester fiber pretreatment:

[0029] a. Immerse the polyester fabric in the treatment solution, and then immerse the ultrasonic probe in the treatment solution. After 19 minutes of ultrasonic treatment at a specific frequency, filter out the polyester fabric, wash it in purified water, and dry it for later use;

[0030] b. Place the polyester fabric treated with the treatment liquid in operation a in a plasma generator for cold plasma treatment, and take it out for use after the treatment is completed;

[0031] (2) Dyeing:

[0032] Immerse the polyester fabric pretreated in step (1) in the dyeing solution, adjust the pH to 5, then raise the temperature in the dyeing solution to 60°C at a rate of 2°C / min, connect the DC magnetic field, and keep the magnetic field strength constant. Immerse the ultrasonic probe in the dyeing solution, and after ...

Embodiment 2

[0045] A kind of dyeing method that improves the disperse dye color fastness of polyester fabric, comprises the steps:

[0046] (1) Polyester fiber pretreatment:

[0047] a. Immerse the polyester fabric in the treatment solution, and then immerse the ultrasonic probe in the treatment solution. After 21 minutes of ultrasonic treatment at a specific frequency, filter out the polyester fabric, wash it in purified water, and dry it for later use;

[0048] b. Place the polyester fabric treated with the treatment liquid in operation a in a plasma generator for cold plasma treatment, and take it out for use after the treatment is completed;

[0049] (2) Dyeing:

[0050] Immerse the polyester fabric pretreated in step (1) in the dyeing solution, adjust the pH to 5.5, then raise the temperature in the dyeing solution to 64°C at a rate of 2.5°C / min, connect the DC magnetic field, and keep the magnetic field strength constant. Immerse the ultrasonic probe in the dyeing solution, and afte...

Embodiment 3

[0063] A kind of dyeing method that improves the disperse dye color fastness of polyester fabric, comprises the steps:

[0064] (1) Polyester fiber pretreatment:

[0065] a. Immerse the polyester fabric in the treatment solution, and then immerse the ultrasonic probe in the treatment solution. After ultrasonic treatment at a specific frequency for 23 minutes, filter out the polyester fabric, wash it in purified water, and dry it for later use;

[0066] b. Place the polyester fabric treated with the treatment liquid in operation a in a plasma generator for cold plasma treatment, and take it out for use after the treatment is completed;

[0067] (2) Dyeing:

[0068] Immerse the polyester fabric pretreated in step (1) in the dyeing solution, adjust the pH to 6, then raise the temperature in the dyeing solution to 68°C at a rate of 3°C / min, connect the DC magnetic field, and keep the magnetic field strength constant. Immerse the ultrasonic probe in the dyeing solution, and after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com