Method for cationic modification and salt-free dyeing of cellulose fiber fabric

A technology of cellulose fiber and cationic modifier, applied in the direction of dyeing, fiber treatment, plant fiber, etc., can solve the problems of color pattern, color sink, ring dyeing, etc., to improve the permeability, uniformity, color fastness, etc. Good, easy and controllable dyeing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

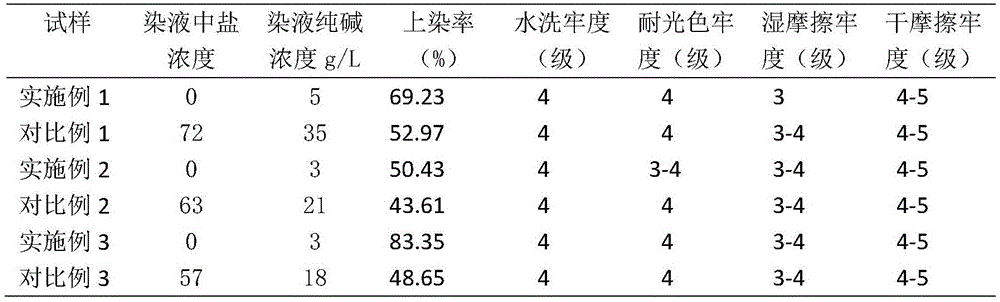

Embodiment 1

[0018] Salt-free and low-alkali dyeing of cotton knitted fabrics. The specific steps are:

[0019] (1) Modification of cotton knitted fabric: the modifier is cationic starch and polyepichlorohydrin-dimethylamine, the mass ratio of the two is 7:3, and the concentration is 12g / L prepared with soft water, according to the liquor ratio The ratio is 1:10. After mixing evenly, add pure cotton cloth to it, and then add NaOH, the concentration of which is 1.8g / L. Apply a pressure of 0.4MPa, raise the temperature to 75°C at a heating rate of 1.0°C / min, and react at a constant temperature for 30 minutes. After the pressure is released and the temperature drops below 60°C, the modifying liquid is discharged, washed with water until the pH value of the discharged liquid is 7.5, and a cationic modified cotton fabric is obtained.

[0020] (2) Dyeing: Arrange the modified cotton prepared in (1) in the dyeing machine, add soft water, the bath ratio is 1:10, dissolve the dye with backflow wa...

Embodiment 2

[0025] Salt-free and low-alkali dyeing of cotton / modal knitted fabrics. The specific steps are:

[0026] (1) Modification of cotton / modal (60 / 40) plain weave fabric: the modifier is cationic polyacrylamide, which is prepared with soft water to a concentration of 6g / L and a bath ratio of 1:18. After mixing evenly, add the fabric to it. Apply a pressure of 0.5MPa, raise the temperature to 70°C at a heating rate of 1.0°C / min, and react at a constant temperature for 40 minutes. Release the pressure, lower the temperature to below 60°C and discharge the modified liquid, wash with water until the pH value of the discharged liquid is 7, and obtain a cationic modified cotton / modal fabric.

[0027] (2) Dyeing: Arrange the modified cotton / modal fabric prepared in (1) in the dyeing machine, add soft water, the bath ratio is 1:7, dissolve the dye with reflux water and inject it into the dyeing machine, the dye prescription is: active Yellow HF-4GL150%: 0.8% owf, active turquoise FG150%:...

Embodiment 3

[0032]Salt-free and low-alkali dyeing of all-tencel plain weave. The specific steps are:

[0033] (1) Modification of all-tencel plain weave fabric: the modifier is polyepichlorohydrin-dimethylamine, which is prepared with soft water to a concentration of 3g / L and a bath ratio of 1:15. After mixing evenly, add the fabric to it. NaOH was then added at a concentration of 1.5 g / L. Apply a pressure of 0.3MPa, raise the temperature to 85°C at a heating rate of 1.5°C / min, and react at a constant temperature for 25 minutes. Release the pressure, lower the temperature to below 60°C and discharge the modified liquid, wash with water until the pH of the discharged liquid is 8, and obtain a cationic modified Tencel fabric.

[0034] (2) Dyeing: Put the modified Tencel fabric prepared in (1) in a dyeing machine, add soft water, the bath ratio is 1:10, dissolve the dye with backflow water and inject it into the dyeing machine, the dye prescription is: reactive yellow HF-4GL150%: 0.22% ow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com