Dye composition for one-bath and one-type based dyeing and dyeing method of dye composition

A dye composition, the technology of the composition, applied in the direction of dyeing method, organic dyes, textiles and paper making, etc., can solve problems such as affecting the dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

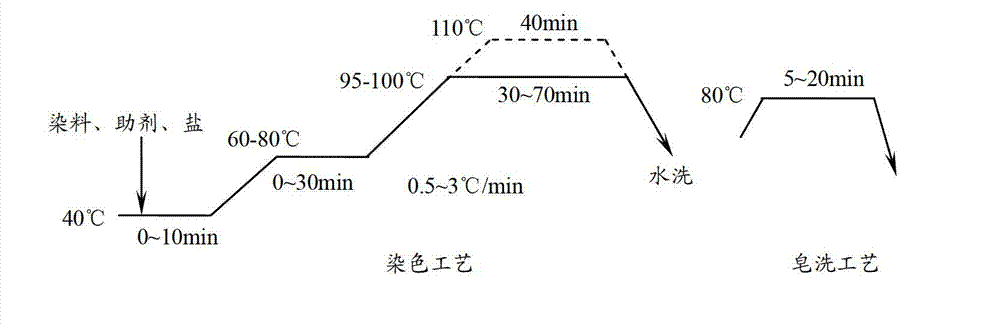

Method used

Image

Examples

Embodiment 1

[0262] Dyeing brocade / viscose (50 / 50) blended roman cloth with dye composition of the present invention

[0263] Dye composition A (black)

[0264]

[0266]

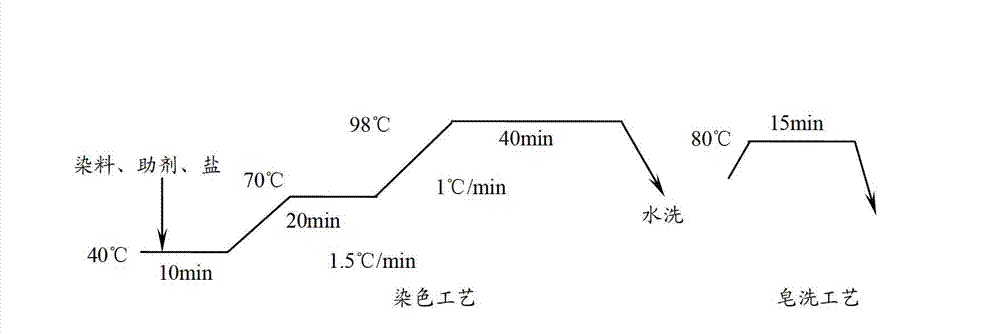

[0267] The dye composition A and brocade / viscose blended fabrics are dyed at room temperature (35°C), and sodium sulfate, leveling agent, sodium bicarbonate, accelerator, etc. are added in sequence, and then the temperature is raised to 70°C for dyeing (according to 1.5°C rate) and keep warm for 20 minutes, continue to heat up to 98°C for dyeing (heating at a rate of 1°C per minute) and keep warm for 40 minutes. After dyeing, cool down to 80°C, and use low-temperature soaping agent to soap for 15 minutes. See the dyeing process flow chart figure 2 :

[0268] After dyeing, the fabric was visually evaluated, and it was found that the dyeing was relatively uniform and the dyeing depth was good. At the same time, the dyed fabrics were tested for fastness, and the results are recorded in Ta...

Embodiment 2

[0274] Dyeing brocade / viscose (50 / 50) blended roman cloth with dye composition of the present invention

[0275] Dye composition B (gray)

[0276]

[0277] Dyeing recipe:

[0278]

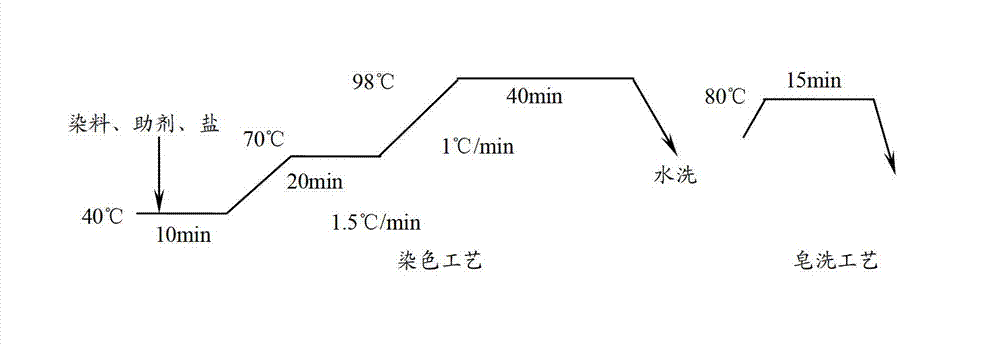

[0279] The dye composition B and brocade / viscose blended fabrics are dyed at room temperature (35°C), and sodium sulfate, leveling agent, sodium carbonate, accelerator, etc. are added in sequence, and then the temperature is raised to 70°C for dyeing (at 1.5°C per minute). ℃ rate) and keep warm for 20 minutes, continue to heat up to 98 ℃ for dyeing (heating at a rate of 1 ℃ per minute) and keep warm for 40 minutes. After dyeing, cool down to 80°C, and use low-temperature soaping agent to soap for 15 minutes. See the dyeing process flow chart image 3 .

[0280] After dyeing, the fabric was visually evaluated, and it was found that the dyeing was relatively uniform and the dyeing depth was good. At the same time, the dyed fabrics were tested for fastness, and the results are recorded in T...

Embodiment 3

[0286] Dyeing Nylon / Cotton (45 / 55) Interwoven Fabric Using the Dyestuff Composition of the Present Invention

[0287] Dye composition C (gray)

[0288]

[0289] Dyeing recipe:

[0290]

[0291] The dye composition C and the nylon / cotton interwoven fabric are dyed at room temperature (35°C), and sodium sulfate, leveling agent, sodium bicarbonate, accelerator, etc. are added in sequence, and then the temperature is raised to 80°C for dyeing (according to each Minutes at a rate of 1.5°C) and keep warm for 30 minutes, continue to heat up to 98°C for dyeing (at a rate of 1°C per minute) and keep warm for 40 minutes. After dyeing, cool down to 80°C, and use low-temperature soaping agent to soap for 15 minutes. See the dyeing process flow chart Figure 4 . :

[0292] After dyeing, the fabric was visually evaluated, and it was found that the dyeing was relatively uniform, the two phases were relatively flat, and the dyeing depth was better. At the same time, the dyed fabri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com