Preparation method of graphene aerogel

A graphene aerogel, graphene technology, applied in the direction of graphene, chemical instruments and methods, general water supply saving, etc., can solve the problem that the graphene aerogel cannot be lightweight and high elasticity, and the photothermal conversion efficiency cannot be fully improved. , graphene foam properties are not easy to control and other problems, to achieve the effect of easy mass production, improve water evaporation efficiency, and improve photothermal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A kind of preparation method of the graphene airgel that is used for seawater desalination or waste water treatment, adopts following steps:

[0027] 1. The sample obtained by spraying the pre-reduced graphene oxide sol with a concentration of 5-50mg / ml, and a reducing agent and / or hydrophilic material can also be added to the pre-reduced graphene oxide sol. Reducing agents that can be used include but are not limited to NaBH 4 , ascorbic acid, ethylenediamine or hydrazine hydrate, the mass ratio of reducing agent to graphene oxide is 0.01-20, the hydrophilic material used is sodium alginate, the mass ratio of hydrophilic material and graphene The ratio is 1:1 to 1:10, and the hydrophilic and hydrophobic properties of graphene airgel are adjusted by compounding hydrophilic materials. When spraying pre-reduced graphene oxide sol, it is necessary to control the nozzle diameter of the spray gun to 1.3-1.8mm, and the spraying distance to be 10-20cm , the ejection volume is...

Embodiment 1

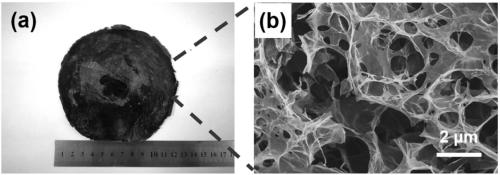

[0032]A graphene oxide sol with a concentration of 15 mg / ml was prepared and ultrasonicated for 2 hours. Take 50ml graphene oxide and add 0.5gNaBH 4 and 0.25g sodium alginate and stir well, put it into the spray gun tank and spray. The nozzle diameter is 1.3mm, the spray distance is 10cm, and the spray volume is 100ml / min. Spraying time is 2 minutes. After the sample was freeze-dried for 48 hours, it was placed in a tube furnace for thermal reduction treatment, protected by Ar gas, the heating rate was 10°C / min, the temperature was raised to 800°C and kept for 1 hour, and naturally cooled to room temperature to obtain graphene airgel . Immerse the obtained graphene airgel in the nano-gold aqueous solution for 30 minutes, take it out and dry it in the air. figure 1 The physical picture and SEM picture of the prepared graphene airgel are shown in a and b, respectively. As shown in the figure, the large-scale graphene airgel prepared by this method has a diameter of about 13...

Embodiment 2

[0034] A graphene oxide sol with a concentration of 10 mg / ml was prepared and ultrasonicated for 3 hours. Take 50ml graphene oxide and add 0.75gNaBH 4 And stir well, put it into the spray gun tank for spraying. The nozzle diameter is 1.3mm, the spray distance is 10cm, and the spray volume is 100ml / min. Spray time 1 minute. After the sample was freeze-dried for 48 hours, it was placed in a tube furnace for thermal reduction treatment, protected by Ar gas, the heating rate was 10°C / min, the temperature was raised to 500°C and kept for 2 hours, and naturally cooled to room temperature to obtain graphene airgel . Immerse the obtained graphene airgel in the nano-gold aqueous solution for 30 minutes, take it out and dry it in the air, and repeat 3 times.

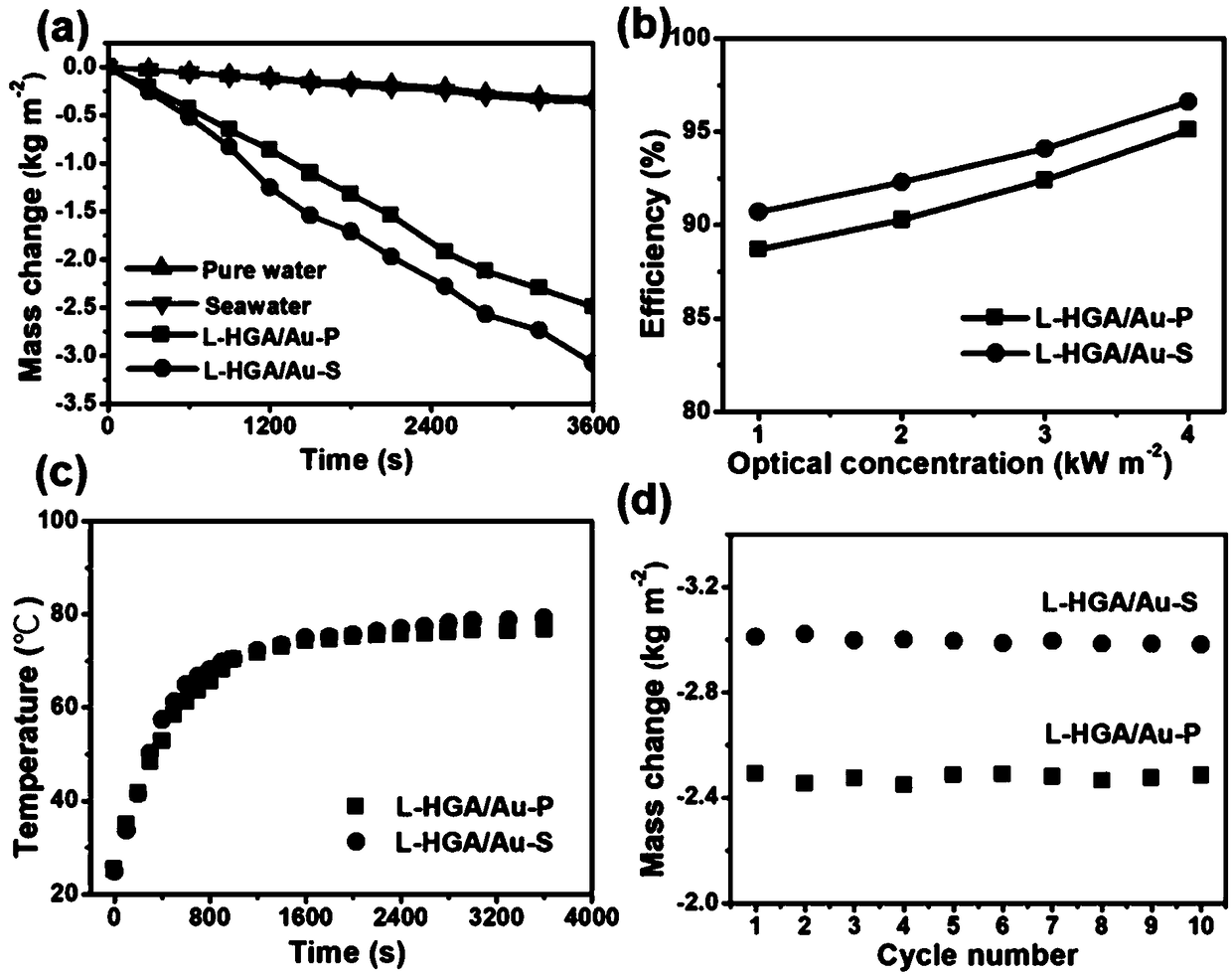

[0035] The solar photothermal conversion water evaporation and seawater desalination performance of the large-area graphene airgel prepared by this method are as follows: figure 2 shown. Figure (a) shows that the light inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com