Photoinduced liquid film pH step-by-step regulation method for synthesizing mesoporous heteroatomic molecular sieve

A heteroatom molecular sieve and liquid membrane technology, applied in molecular sieve compounds, molecular sieve characteristic silicates, chemical instruments and methods, etc., can solve the problems of complex chelating agent structure, limited metal elements, complicated synthesis operations, etc., and reduce the reaction heat effect. , The effect of fast curing rate and controllable light parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0024] 25g of tetrabutyl titanate stabilized with acetylacetone, 1000g of tetraethyl silicate, 100g of P123, 10g of Irgacure 103 and 20g of Irgacure 907 were mixed and stirred evenly to obtain a coating solution;

[0025] Under the condition of ambient humidity of 30-90%, apply the above-mentioned coating solution evenly on the porous ceramic substrate to form a liquid film, and the final thickness of the liquid film is controlled at 1-50 μm;

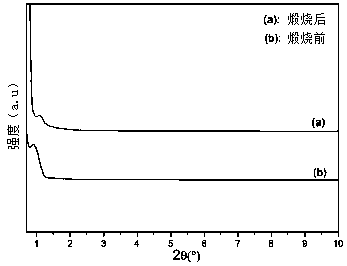

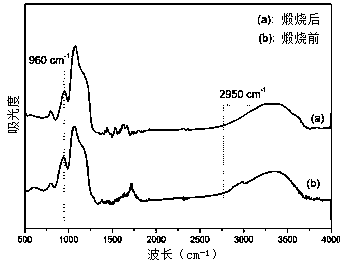

[0026] Use ultraviolet light with a wavelength of 350nm and an intensity of 50% to irradiate the liquid film applied on the substrate for photoreaction for 30 minutes to decompose Irgacure 103, and then use ultraviolet light with a wavelength of 300nm and an intensity of 50% to irradiate the liquid film applied on the substrate. The membrane was subjected to a light reaction for 30 minutes to decompose the Irgacure 907, and realize the step-by-step regulation of the pH of the liquid membrane from acidic to alkaline, and obtain a mesoporo...

Embodiment approach 2

[0030] 25 g of tetrabutyl titanate stabilized with acetylacetone, 1000 g of tetraethyl silicate, 250 g of P123, 25 g of Irgacure 103 and 35 g of Irgacure 907 were mixed and stirred evenly to obtain a coating solution;

[0031] Under the condition of ambient humidity of 30-90%, apply the above-mentioned coating solution evenly on the porous ceramic substrate to form a liquid film, and the final thickness of the liquid film is controlled at 1-50 μm;

[0032] Use ultraviolet light with a wavelength of 390nm and an intensity of 20% to irradiate the liquid film applied on the substrate for photoreaction for 20 minutes to decompose Irgacure 103, and then use ultraviolet light with a wavelength of 320nm and an intensity of 20% to irradiate the liquid film applied on the substrate. The membrane undergoes photoreaction for 20 minutes to decompose Irgacure 907, realize the step-by-step regulation of liquid membrane pH from acidic to alkaline, and obtain a mesoporous heteroatom molecular ...

Embodiment approach 3

[0035] 25 g of tetrabutyl titanate stabilized with acetylacetone, 1000 g of tetraethyl silicate, 500 g of P123, 50 g of Irgacure 103 and 50 g of Irgacure 907 were mixed and stirred evenly to obtain a coating solution;

[0036] Under the condition of ambient humidity of 30-90%, apply the above-mentioned coating solution evenly on the porous ceramic substrate to form a liquid film, and the final thickness of the liquid film is controlled at 1-50 μm;

[0037] Use ultraviolet light with a wavelength of 420nm and an intensity of 90% to irradiate the liquid film applied on the substrate for photoreaction for 10 minutes to decompose Irgacure 103, and then use ultraviolet light with a wavelength of 350nm and an intensity of 90% to irradiate the liquid film applied on the substrate. The membrane undergoes photoreaction for 10 minutes to decompose Irgacure 907, realize the step-by-step regulation of liquid membrane pH from acidic to alkaline, and obtain a mesoporous heteroatom molecular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com