Oriented microchannel stent for promoting tissue regeneration and preparation method of stent

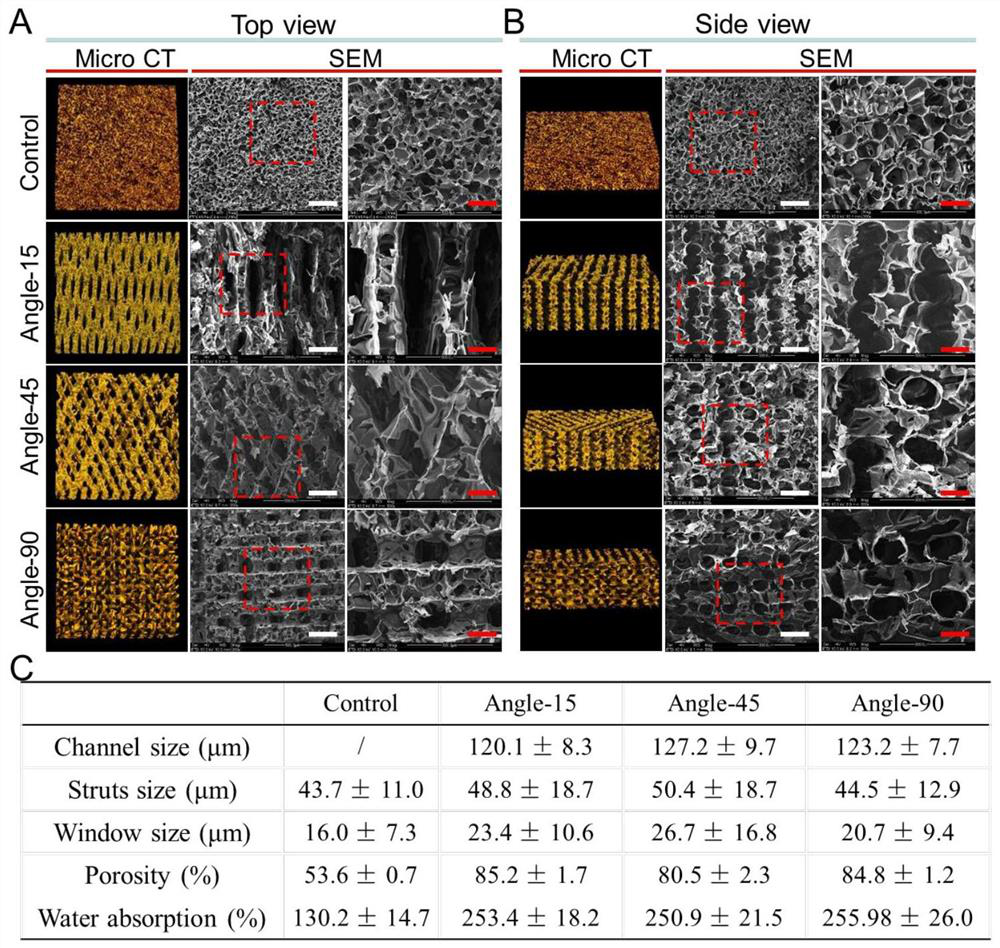

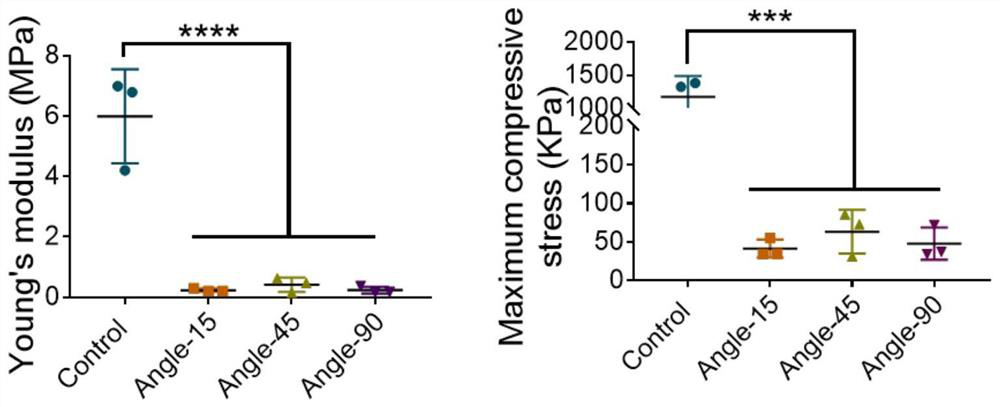

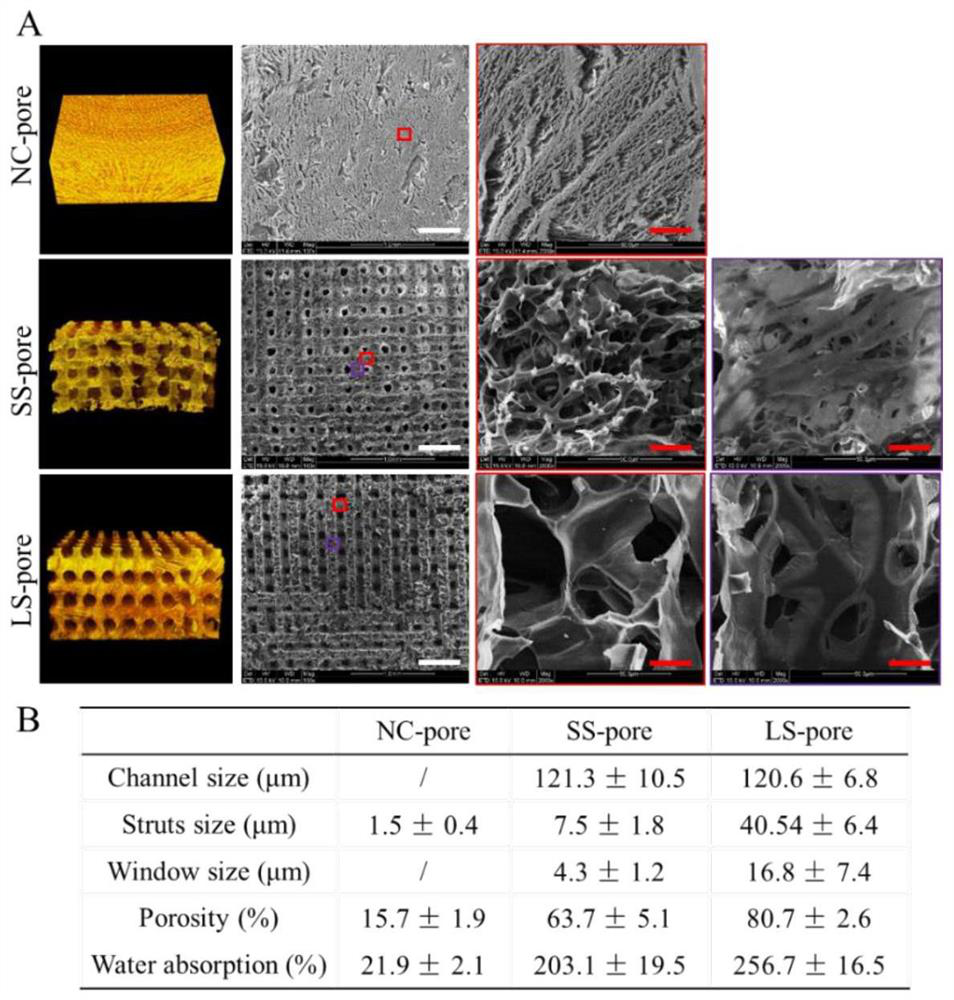

A tissue regeneration and microchannel technology, which can be used in tissue regeneration, pharmaceutical formulations, prostheses, etc., and can solve the problems of difficult to control pore size, random structure of porous protein scaffolds, and limitations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of Nanoscale Porous Silk Fibroin Scaffolds by Electrospinning Using PCL as a Template

[0033] Preparation of PCL nanofiber scaffold: Weigh 2.5 grams of PCL with a molecular weight of 80,000, add it to 10 ml of dichloromethane, stir and dissolve at room temperature until clear, and prepare a PCL solution with a concentration fraction of 25% (m / v). Electrospinning was performed at room temperature with a relative humidity of 60%. Cover the electrospinning drum receiving device with aluminum foil and ground it, put 25% (m / v) PCL spinning solution into a disposable syringe with a diameter of about 14.95 mm, and connect the high voltage DC power supply to the syringe needle. Adjust the needle of the syringe to the center of the cylindrical receiver, set the distance between the needle and the receiver to be 12 cm, the flow rate of the solution to be 2 ml / h, the DC voltage to be 16 kV, and the spinning time to be 40 min. After the preparation is completed, the o...

Embodiment 2

[0037] Fabrication of micron-sized porous chitosan scaffolds by melt spinning using PLGA as a template

[0038] Preparation of PLA crude fiber scaffold: the scaffold was prepared at room temperature by melt spinning. 20 grams of PLA was added to the barrel. Raise the temperature of the barrel to 100°C for 5 hours, adjust the distance between the needle of the barrel and the receiving rod, set the advancing speed of the barrel to 2ml / h, and the moving speed of the x-axis and y-axis of the receiving plate to 1mm / s. It is 15cm, and the spinning time is 60min.

[0039] Preparation of chitosan solution: 10 g of chitosan was weighed and dissolved in 50 ml of acetic acid solution to obtain a 2% chitosan solution.

[0040] Preparation of porous chitosan scaffold: Immerse the PLA fiber template scaffold into the chitosan solution. After the solution is fully immersed in the scaffold, it can be frozen at -20°C, -80°C or liquid nitrogen respectively. After completion, the samples were...

Embodiment 3

[0042] Fabrication of micron-sized porous sodium alginate scaffolds by wet spinning using PLCL as a template

[0043] Preparation of PLCL microfiber scaffold: The scaffold was prepared in a fume hood at room temperature by wet spinning. Weigh 1.5g of PLCL and dissolve it in 10ml of tetrahydrofuran, stir overnight at room temperature to dissolve, and prepare a PLCL solution with a concentration fraction of 15% (mass / volume). Connect a cylindrical receiving rod with a diameter of 2 cm to a rotating motor. Inhale the PLCL spinning solution into the syringe, set the distance between the syringe needle and the receiving rod immersed in the ethanol coagulation bath to be 1cm, the spinning speed to be 2ml / h, the rotating speed of the receiving rod to be 500rpm, and the spinning time to be 30min. After the preparation is completed, the micron fiber scaffold is vacuum-dried for future use.

[0044] Preparation of sodium alginate solution: 10 g of chitosan was weighed and dissolved in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com