High-entropy ceramic powder and preparation method thereof, and high-entropy ceramic block

A technology of ceramic powder and ceramic block, which is applied in the field of high-entropy ceramic powder and its preparation, and high-entropy ceramic block, which can solve the problems of raw material risk, poor quality of finished products, and inability to realize large-scale production, so as to reduce sintering Effects of temperature and grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a preparation method of high-entropy ceramic powder, comprising the following steps:

[0026] La(NO 3 ) 3 , Co(NO 3 ) 2 , Cr(NO 3 ) 3 , Fe(NO 3 ) 3 , Mn(NO 3 ) 2 and Ni(NO 3 ) 2 The mixed solution of the mixed solution is mixed with ammonia water to carry out co-precipitation reaction, and the high-entropy ceramic precursor powder is obtained after solid-liquid separation; the pH value of the co-precipitation reaction is 9-10;

[0027] The high-entropy ceramic precursor powder is subjected to heat treatment to obtain a high-entropy ceramic powder; the temperature of the heat treatment is 1000-1400°C.

[0028] The present invention will La(NO 3 ) 3 , Co(NO 3 ) 2 , Cr(NO 3 ) 3 , Fe(NO 3 ) 3 , Mn(NO 3 ) 2 and Ni(NO 3 ) 2 The mixed solution is mixed with ammonia water for co-precipitation reaction. In the present invention, the molar ratio of La ions, Co ions, Cr ions, Fe ions, Mn ions and Ni ions in the mixed solution is prefe...

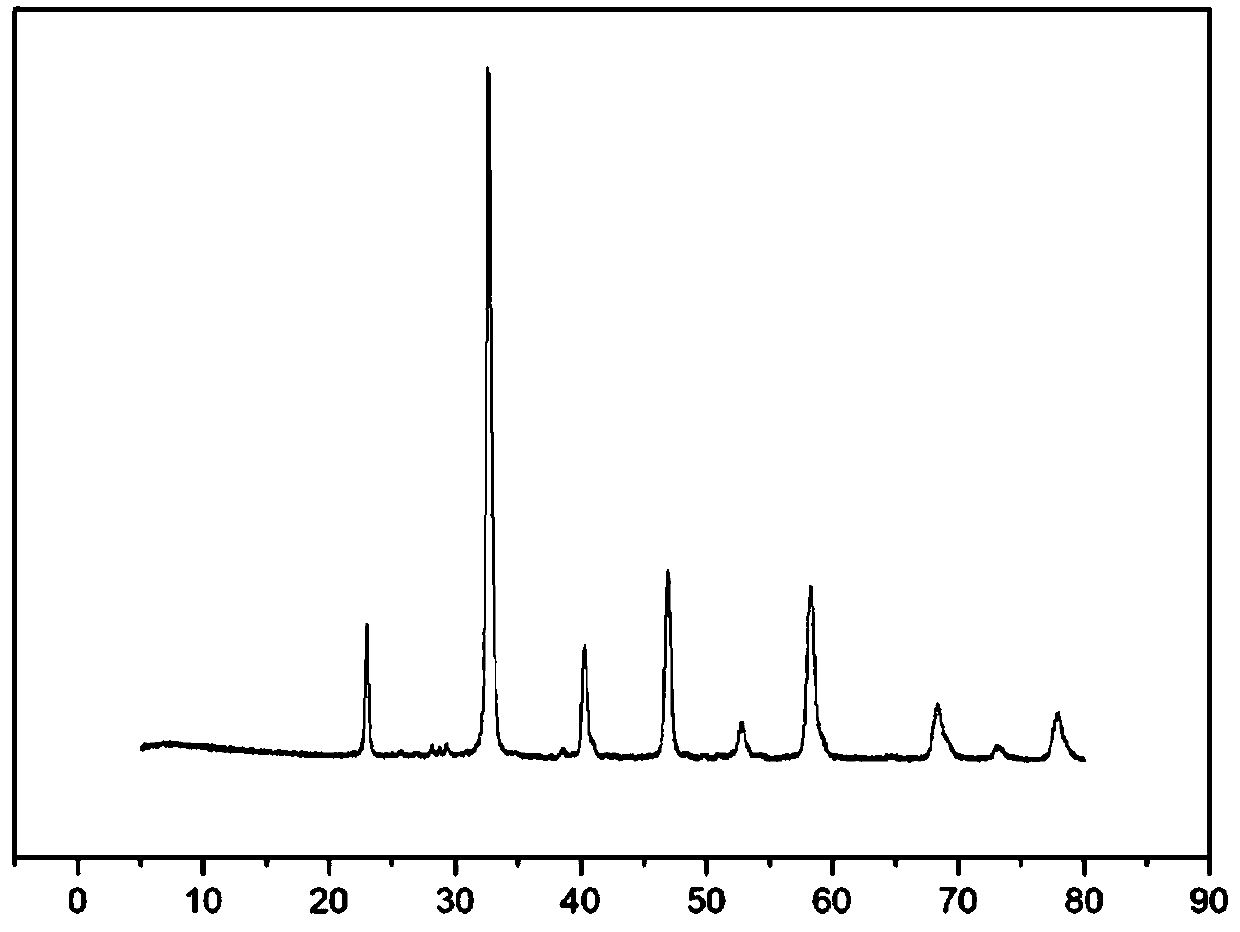

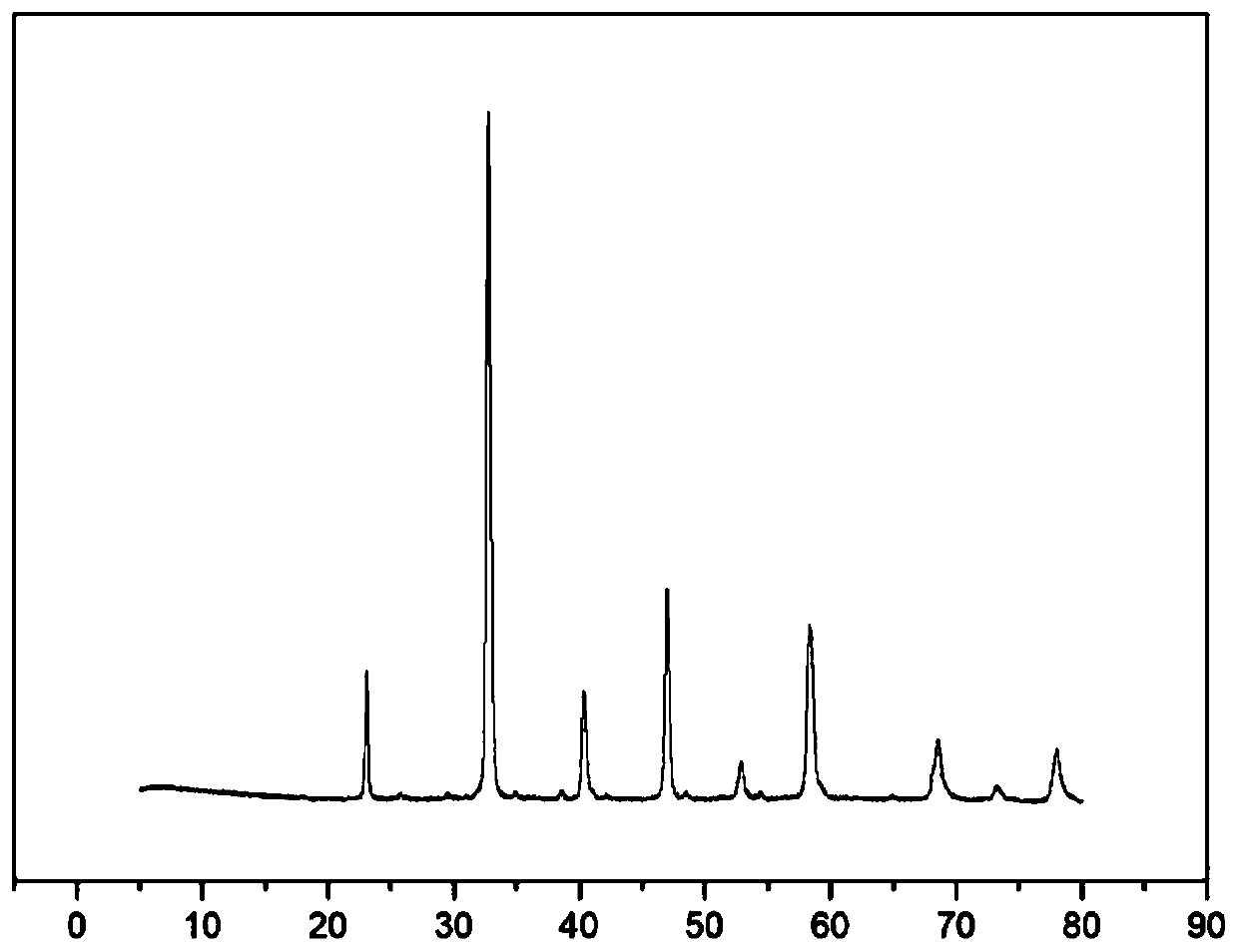

Embodiment 1

[0039] La(Co 0.2 Cr 0.2 Fe 0.2 mn 0.2 Ni 0.2 )O 3 The preparation method of high-entropy ceramic powder, the preparation steps are as follows:

[0040] Step 1: Weigh 10.83g La(NO 3 ) 3 , 1.46g Co(NO 3 ) 2 , 2.00g Cr(NO 3 ) 3 , 2.02g Fe(NO 3 ) 3 , 1.26g Mn(NO 3 ) 2 and 1.45gNi(NO 3 ) 2 , the molar ratio of La ions, Co ions, Cr ions, Fe ions, Mn ions and Ni ions is 5:1:1:1:1:1; they are mixed and dissolved in 200mL deionized water to form a mixed solution, The solution was stirred evenly, and the mixed solution was slowly poured into 300mL of ammonia solution (pH value = 9) and kept stirring, while continuously dripping ammonia water to keep the pH of the solution; after the precipitation was complete, the precipitate was filtered and washed with ammonia water, and finally the The precipitation is dried at 100°C to obtain an amorphous precursor powder with uniform composition;

[0041] Step 2: Heat the precursor powder obtained in step 1 at 1000°C for 6 hours t...

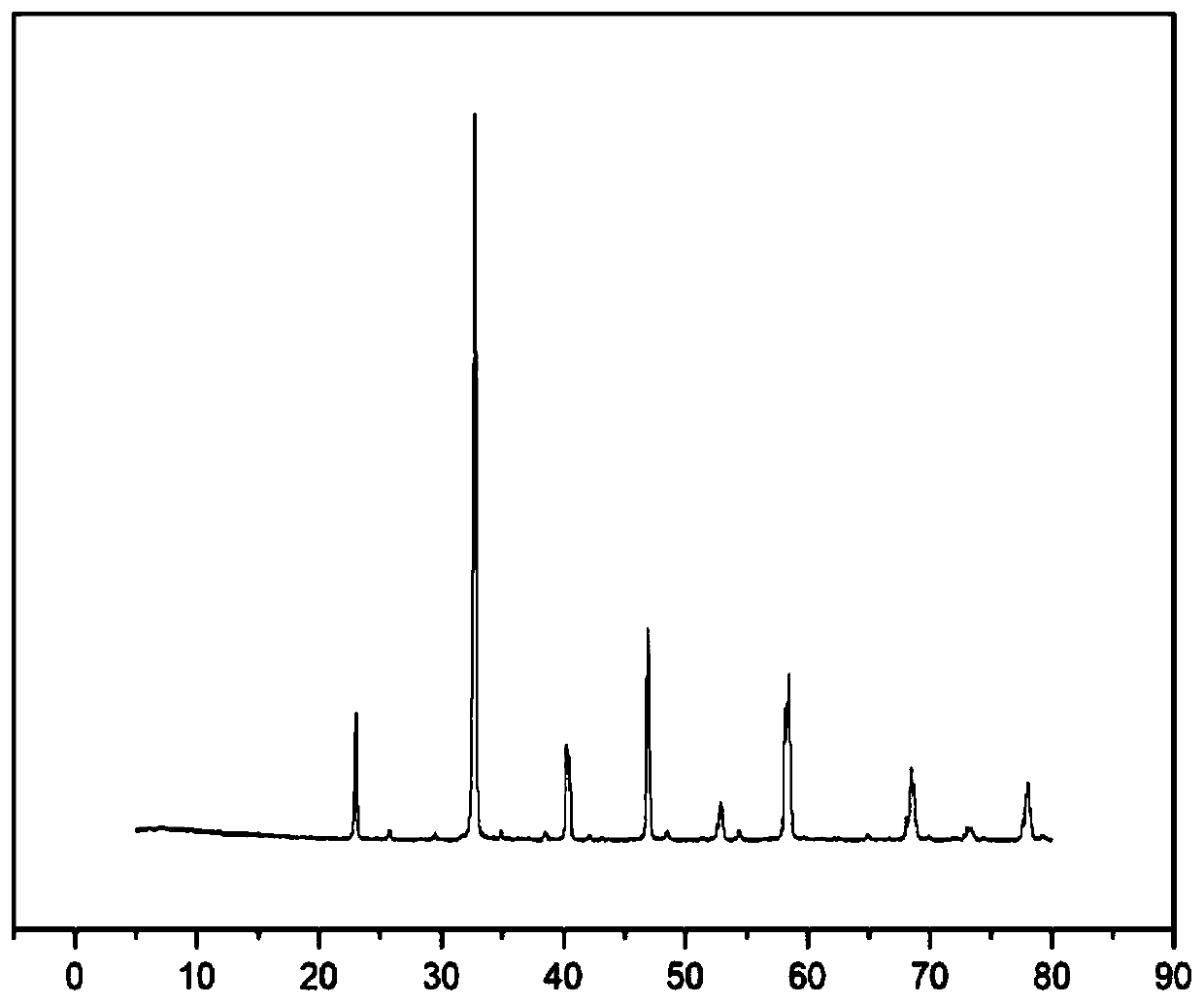

Embodiment 2

[0044] Prepare the high-entropy ceramic powder obtained in step 2 of Example 1 into a high-entropy ceramic block: put the high-entropy ceramic powder into a graphite mold, seal the graphite mold, and then place the mold in a discharge plasma furnace Sintering in the medium to obtain La(Co 0.2 Cr 0.2 Fe 0.2 mn 0.2 Ni 0.2 )O 3 High-entropy ceramic blocks;

[0045] Sintering equipment: discharge plasma sintering furnace;

[0046] Heating method: AC pulse current;

[0047] Sintering temperature: 1400°C;

[0048] Sintering time: 5min;

[0049] Heating rate: 50°C / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com