High-throughput preparation device and method for high-silicon aluminum alloy structural gradient material used for packaging

A technology of high-silicon aluminum alloy and structural gradient, which is applied in the field of material processing, can solve the problems affecting the application of high-silicon aluminum alloy, mechanical and welding performance deterioration, etc., and achieve excellent comprehensive performance, high density, and wide equipment practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

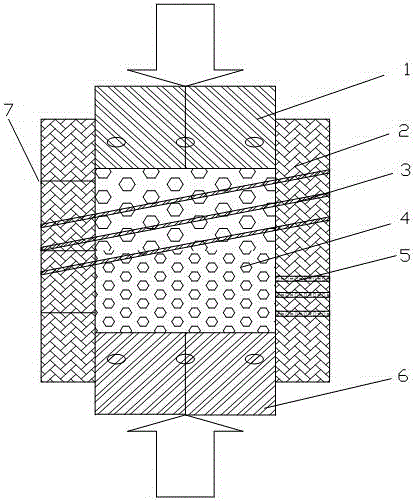

Image

Examples

preparation example Construction

[0034] The high-throughput preparation method of the high-silicon aluminum alloy structure gradient material for packaging of the present invention comprises the following steps:

[0035] Step 1, providing atomized powder for preparing gradient high-silicon aluminum alloy, the main components (mass percentage, wt.%) of the atomized powder of gradient high-silicon aluminum alloy are Al-50wt.%Si, Al-20wt.% Si, Al-12.6wt.%Si. The gradient encapsulation material prepared by the invention can be powders with two different mass fractions, or powders with three different mass fractions.

[0036] Step 2: Select two or three kinds of atomized powders of the gradient high-silicon aluminum alloys prepared above, and add the low-composition alloy powder at the bottom of the outer mold, and the high-composition alloy powder at the top of the outer mold. Volume percent 5 (high composition): 1 (low composition). Firstly, alloy powder with low silicon content is spread on the bottom of the ...

example 1

[0039] Example 1: Al-20wt.%Si / Al-12.6wt.%Si Gradient Alloy

[0040]According to step 1, select Al-20wt.%Si and Al-12.6wt.%Si atomized alloy powder to prepare gradient alloy, and according to step 2, firstly put Al-12.6wt.%Si atomized with a thickness of 10mm at the bottom of the mold Alloy powder, followed by Al-20wt.%Si alloy powder with a thickness of 50mm. A pressure of 10KN was applied to the added powder at room temperature. According to step 3, the induction coil is used to heat the cold-pressed powder. According to step 3, the highest sintering temperature of Al-20wt.%Si alloy powder is 520°C, and the highest sintering temperature of Al-12.6wt.%Si alloy powder is 450°C. The induction coil first heats the high-composition alloy. When the maximum temperature of the powder reaches 520°C controlled by the thermocouple, the induction coil starts to reduce the power and moves to the lower end of the mold. When moving to the sample gradient area, the temperature control does...

example 2

[0041] Example 2: Al-50wt.%Si / Al-20wt.%Si gradient alloy

[0042] According to step 1, select Al-50wt.%Si and Al-20wt.%Si atomized alloy powder to prepare gradient alloy, and according to step 2, first put Al-20wt.%Si atomized alloy powder with a thickness of 10mm at the bottom of the mold , followed by adding Al-50wt.%Si alloy powder with a thickness of 50mm. A pressure of 10KN was applied to the added powder at room temperature. According to step 3, use the induction coil to heat the cold-pressed powder. According to step 3, the highest sintering temperature of Al-50wt.%Si alloy powder is 570°C, and the highest sintering temperature of Al-20wt.%Si alloy powder is 520°C. The induction coil first heats the high-composition alloy. When the maximum temperature of the powder reaches 570°C controlled by the thermocouple, the induction coil starts to reduce the power and moves to the lower end of the mold. When moving to the sample gradient area, the temperature control does not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com