Graphene-zirconium oxide compound material and preparation method of same

A composite material and zirconia technology, applied in the field of ceramic materials, can solve problems such as difficulty in obtaining uniformly dispersed graphene, difficulty in ensuring uniform distribution of graphene, weakening its own mechanical properties, etc., and achieves good reduction effect, few steps, and improved mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

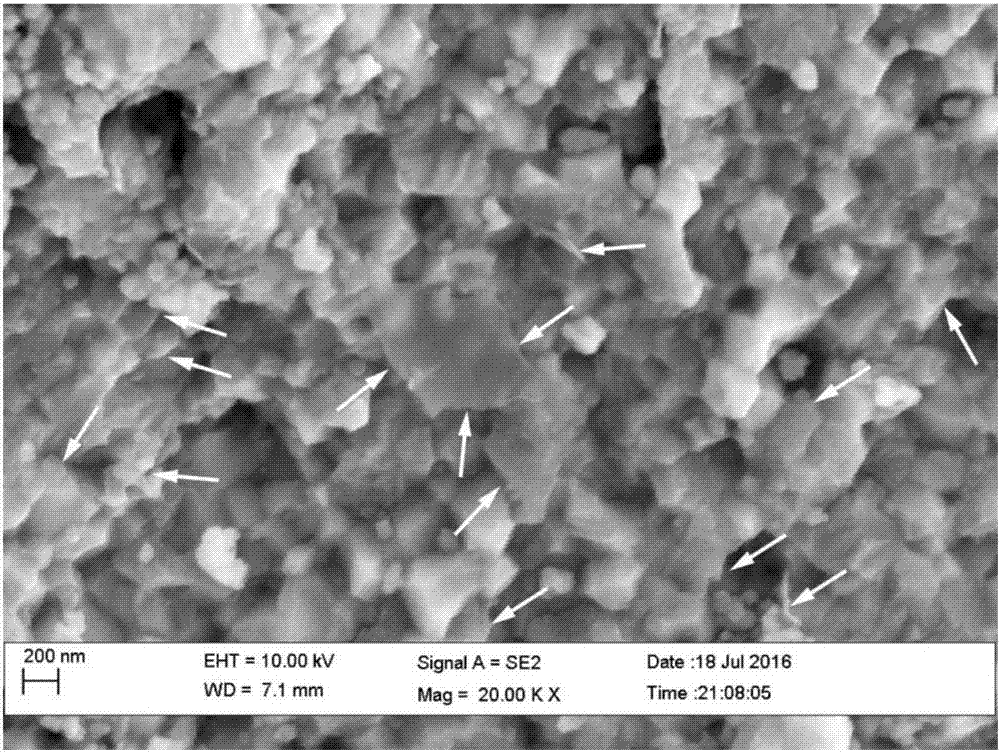

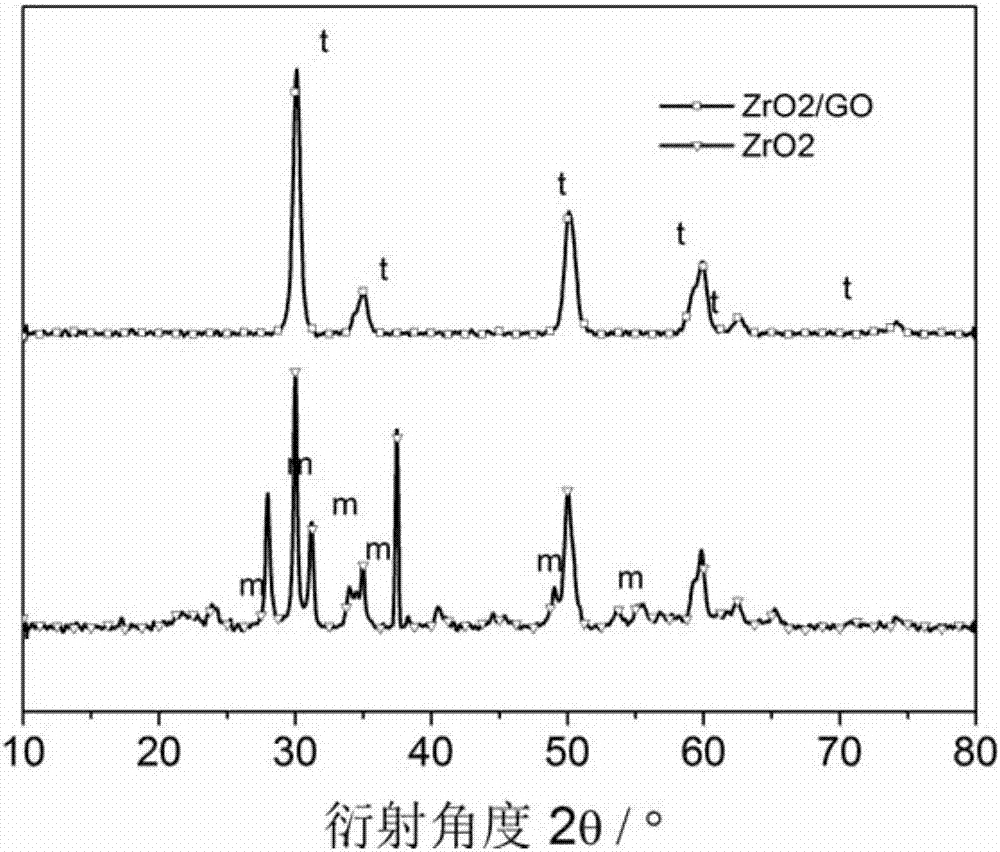

[0033] A graphene-zirconia composite material and a preparation method thereof, comprising the following steps and process conditions thereof:

[0034] (1) Dispersion and mixing of ingredients

[0035] According to the total mass percentage of zirconia granulated powder and graphene oxide, the mass ratio: zirconia granulated powder 99.9wt.%, graphene oxide 0.1wt.%; the zirconia granulated powder and graphene oxide are mixed uniformly in water , adding the granulated powder of zirconia to the aqueous suspension of graphene oxide to prepare a mixed powder with uniform dispersion of graphene oxide;

[0036] (2) Sintering mixed powder

[0037] Put the mixed powder in step (1) into a φ20mm graphite mold, adopt spark plasma sintering technology, apply an axial pressure of 30MPa, a sintering heating rate of 100°C / min, a sintering temperature of 1350°C, and a sintering vacuum of 10 -2 Pa, the holding time is 3min, and the graphene-zirconia composite material is prepared.

[0038] T...

Embodiment 2

[0041] A graphene-zirconia composite material and a preparation method thereof, comprising the following steps and process conditions thereof:

[0042] (1) Dispersion and mixing of ingredients

[0043] According to the total mass percentage of zirconia granulated powder and graphene oxide, the mass ratio: zirconia granulated powder 99.99t.%, graphene oxide 0.01wt.%; zirconia granulated powder and graphene oxide are mixed in water , adding the granulated powder of zirconia to the aqueous suspension of graphene oxide to prepare a mixed powder with uniform dispersion of graphene oxide;

[0044] (2) Sintering mixed powder

[0045] Put the mixed powder in step (1) into a φ20mm graphite mold, adopt spark plasma sintering technology, apply an axial pressure of 60MPa, a sintering heating rate of 50°C / min, a sintering temperature of 1550°C, and a sintering vacuum of 10 -3 Pa, the holding time is 5min, and the graphene-zirconia composite material is prepared.

Embodiment 3

[0047] A graphene-zirconia composite material and a preparation method thereof, comprising the following steps and process conditions thereof:

[0048] (1) Dispersion and mixing of ingredients

[0049] According to the total mass percentage of zirconia granulated powder and graphene oxide, the mass ratio: zirconia granulated powder 99.5wt.%, graphene oxide 0.5wt.%; the zirconia granulated powder and graphene oxide are mixed uniformly in water , adding the granulated powder of zirconia to the aqueous suspension of graphene oxide to prepare a mixed powder with uniform dispersion of graphene oxide;

[0050] (2) Sintering mixed powder

[0051] Put the mixed powder in step (1) into a φ20mm graphite mold, adopt spark plasma sintering technology, apply an axial pressure of 40MPa, a sintering heating rate of 150°C / min, a sintering temperature of 1300°C, and a sintering vacuum of 10 -2 Pa, holding time 4min.

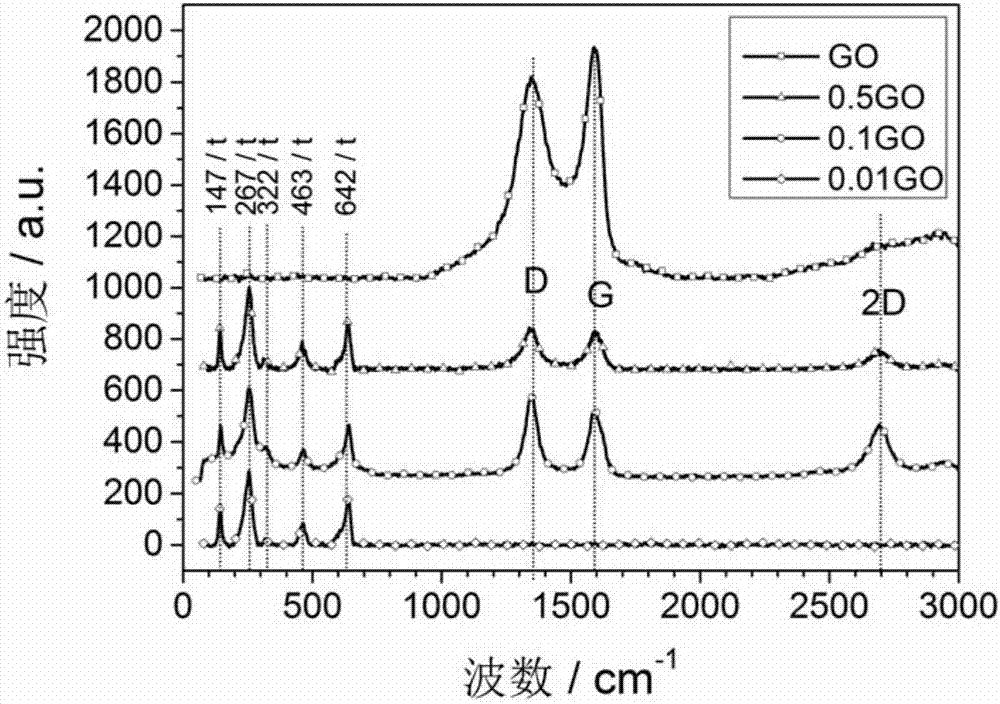

[0052] The Raman contrast spectrogram of the graphene-zirconia composite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com