Fault location detection method, fault location detection device, storage battery assembly and motor vehicle

A technology of fault location and detection method, applied in the direction of measuring device, measuring electricity, measuring electrical variables, etc., can solve the problem of life reduction, the specific location of the power failure failure cannot be detected, and the driver or maintenance personnel cannot know the power failure identification. and other problems to achieve the effect of reducing maintenance time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

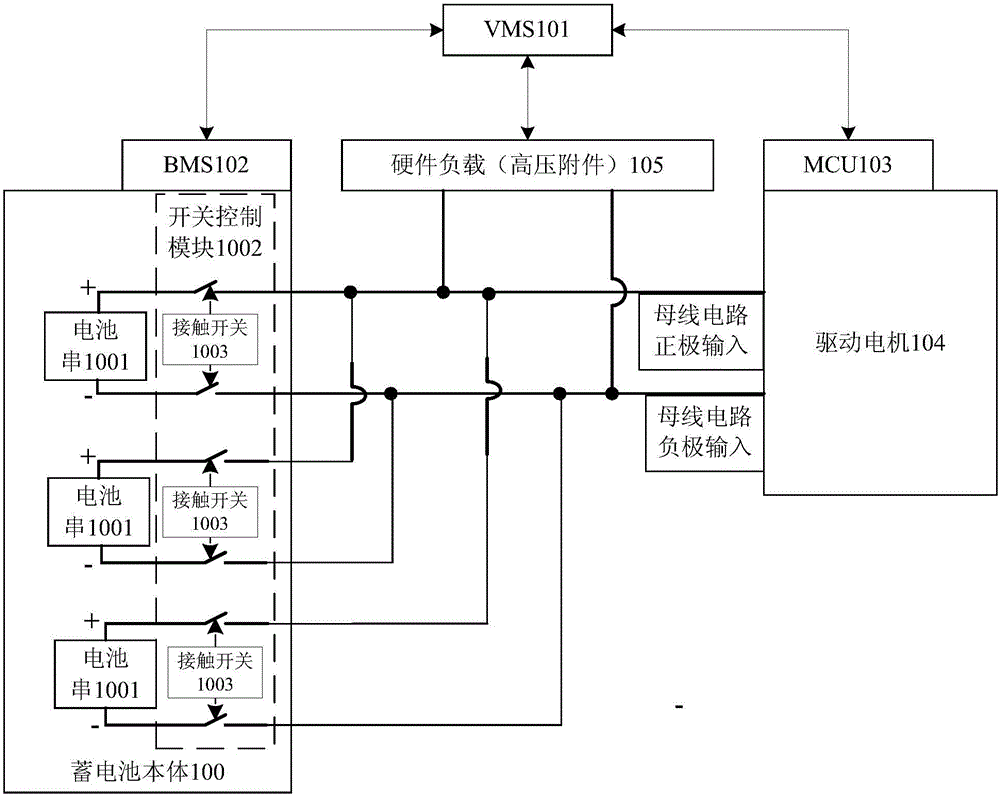

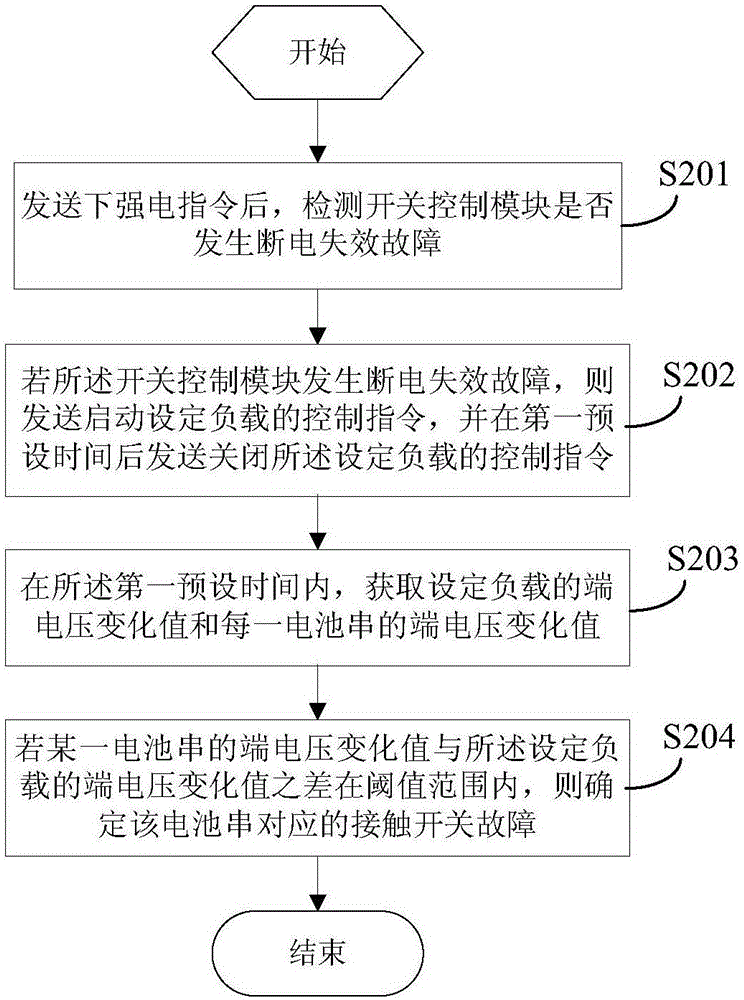

[0049] The fault location detection method described in this embodiment is applied in a vehicle management system, such as figure 2 shown, including the following steps:

[0050] S201: After sending the high power down command, detect whether the switch control module has a power failure failure, the power down power command is used to control each contact switch in the switch control module to be disconnected.

[0051] S202: If the switch control module fails due to power failure, send a control command to start the set load, and send a control command to turn off the set load after a first preset time. Wherein, the set load is one or more of the hardware loads, such as a high-pressure water pump and a high-pressure fan; the first preset time can be determined according to the configuration of the power system, and in principle, the fault location can be ensured as much as possible short.

[0052] S203: Obtain the change value of the terminal voltage of the set load and th...

Embodiment 2

[0058] Figure 4 Taking the failure of a battery string as an example, a schematic flowchart of a fault location detection method is provided, including:

[0059] S401 : After sending the command to turn off the high power, detect whether the switch control module has a power failure failure; after that, perform fault location and go to step S402 .

[0060] S402: At the initial moment T1 of the first preset time, obtain the initial voltage Bat1_Vol(T1) of the first battery string, the initial voltage Bat2_Vol(T1) of the second battery string, the initial voltage Bat3_Vol(T1) of the third battery string, and the bus circuit The initial voltage Bus_Vol(T1), in this step, the above data can be obtained by obtaining the voltage value of the branch circuit connected in series with each battery string through the BMS.

[0061] S403: When the duration t1=0, the VMS sends a control instruction for starting the set load, so as to start the set load.

[0062] S404: Determine whether t...

Embodiment 3

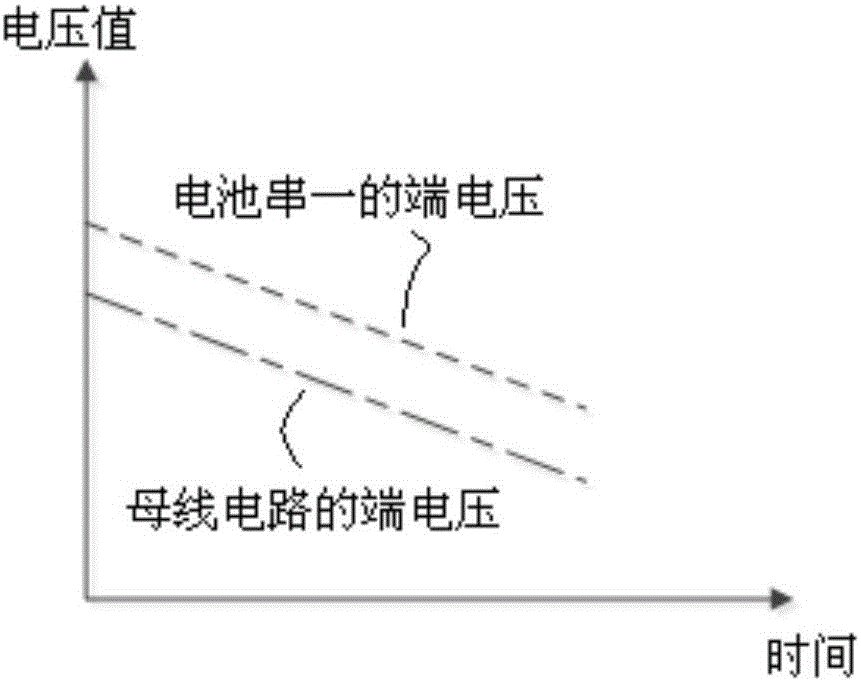

[0077] This embodiment provides another solution for obtaining the change value of the terminal voltage of the set load and the change value of the terminal voltage of each battery string, which specifically includes the following steps:

[0078] S1031: Obtain first voltage-time distribution information of the bus circuit and second voltage-time distribution information of the branch circuit;

[0079] S1032: Determine the first effective voltage value and the initial voltage of the bus circuit at the initial moment of the first preset time according to the first preset sampling frequency and the first voltage-time distribution information; according to the first The preset sampling frequency and the second voltage-time distribution information determine the second effective voltage value and the initial voltage of the branch circuit at the initial moment of the first preset time;

[0080] S1033: Determine a first sampling moment according to the first preset sampling frequency...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com