Spark plasma sintering system

A discharge plasma and sintering furnace technology, applied in the field of ion sintering system, can solve the problems of large side temperature measurement barrier, unsatisfactory product quality, poor temperature control effect, etc., achieve high measurement and control accuracy, increase contact area, good molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

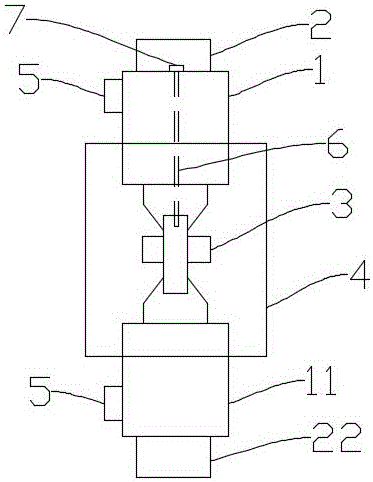

[0033] The technical scheme in the embodiment of the present invention is described below in conjunction with accompanying drawing:

[0034] Reference attached figure 1 , a spark plasma sintering system, including a sintering furnace and a control system connected thereto, the control system includes a pressure / displacement control system, an atmosphere control system, a vacuum control system and a temperature control system; the sintering furnace includes a pressurized device and a pulse current generator, the pressurizing device includes a corresponding upper indenter 1 and a lower indenter 11, an upper electrode 2 and a lower electrode 22 respectively arranged on the upper and lower sides of the upper indenter 1 and the lower indenter 11 , the sintering mold 3 arranged between the upper pressing head 1 and the lower pressing head 11, and the water-cooled vacuum chamber 4 arranged outside the sintering mold 3, the pulse current generator is connected with the upper electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com