Anhydrous stemming and preparation method thereof

A technology of anhydrous taphole clay and white clay, which is applied in the field of refractory material preparation, can solve the problems of taphole clay not being able to be tapped normally, use, and cumbersome procedures, and achieve high strength, stable volume, good plasticity and cohesiveness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

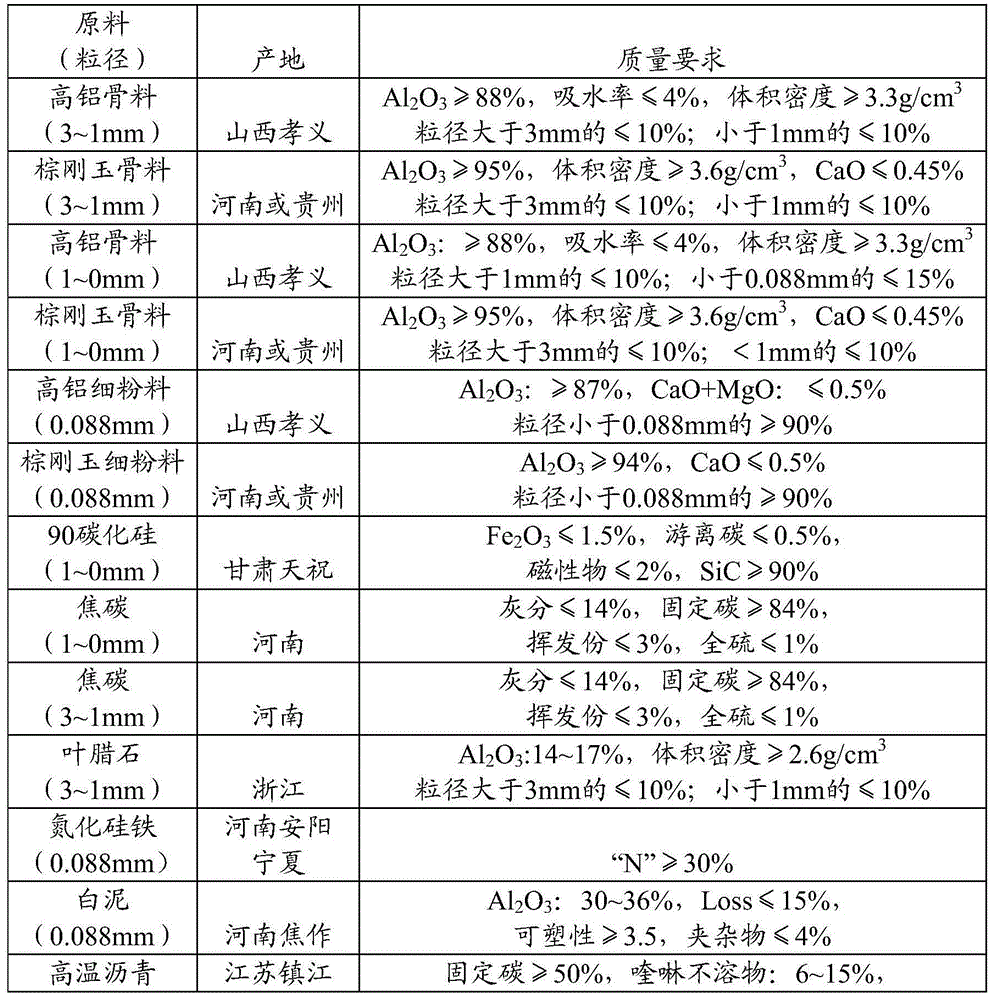

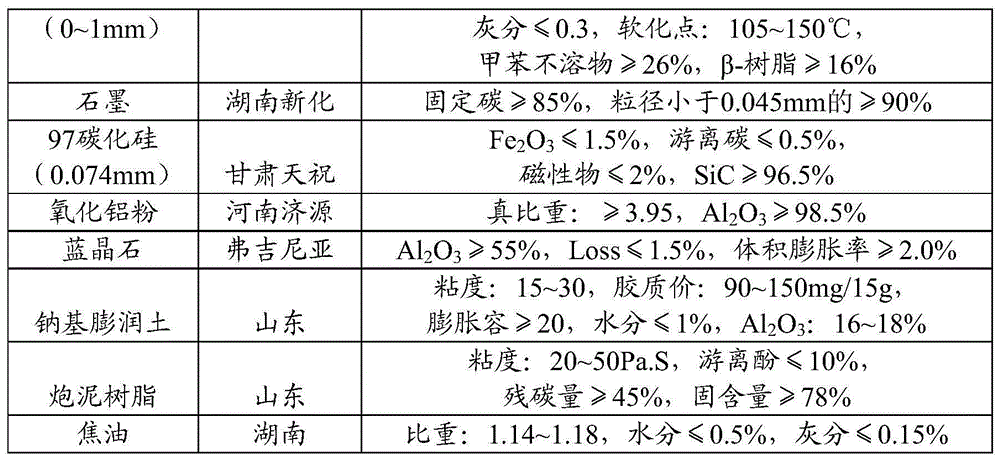

[0051] The present invention also provides a method for preparing anhydrous gun mud, which includes the following steps:

[0052] A) In terms of mass fraction, mix 2 to 5% of sodium bentonite and 8 to 15% of additives to obtain a premix;

[0053] B) In terms of mass fraction, mix 15-40% aluminum-containing aggregate, 3-10% coke, 10-30% silicon carbide, 5-10% pyrophyllite, and 10-20% ferrosilicon nitride , 5-10% aluminum-containing fine powder, 5-10% white mud and 2-6% high-temperature asphalt are mixed with the premix obtained in step A) to obtain a mixture;

[0054] C) In terms of mass fraction, mix 5-15% of tar with the mixture obtained in step B) to obtain anhydrous gun mud;

[0055] The particle size of the aluminum-containing aggregate>0.088mm and ≤3mm;

[0056] The particle size of the aluminum-containing fine powder is> 0 mm and ≤ 0.088 mm;

[0057] The softening point of the high-temperature asphalt is preferably 105-150°C.

[0058] In terms of mass fraction, the present inventio...

Embodiment 1

[0072] Premix 2.6% graphite, 4.4% alumina powder, 2.6% kyanite and 2.6% sodium bentonite in a cone premixer for more than 30 minutes to obtain a premix;

[0073] 8.8% of the high alumina aggregate with a particle size of 1~3mm, 5.3% of the brown corundum aggregate with a particle size of 1~3mm, 3.5% of the high alumina aggregate with a particle size of 0~1mm, 4.4 % Brown corundum aggregate with a particle size of 0~1mm, 4.4% high-alumina fine powder with a particle size of 0.088mm, 1.8% of brown corundum fine powder with a particle size of 0.088mm, 2.6% of a particle size of 0~ Coke between 1mm, 1.8% coke with a particle size of 1~3mm, 8.8% 90 silicon carbide, 8.8% 97 silicon carbide, 5.3% pyrophyllite, 13.2% ferrosilicon nitride, 5.3% white mud and 1.8% high-temperature asphalt is mixed with the obtained premix, put into a heated gun mud mixer, dry-mixed and stirred for more than 5 minutes to obtain a mixture;

[0074] The obtained mixture was wet-mixed with 4.4% gun clay resin w...

Embodiment 2

[0078] Premix 2.6% graphite, 3.5% alumina powder, 2.6% kyanite and 3.5% sodium bentonite in a cone premixer for more than 30 minutes to obtain a premix;

[0079] 14.2% of the brown fused alumina aggregate with a particle size of 1~3mm, 8% of the brown fused alumina aggregate with a particle size of 0~1mm, 6.2% of the brown fused alumina fine powder with a particle size of 0.088mm, 7% Coke with diameter of 1~3mm, 7% 90 silicon carbide, 8.8% 97 silicon carbide, 2.6% pyrophyllite, 16% ferrosilicon nitride, 4.4% white mud and 1.8% high-temperature asphalt are mixed with the obtained premix Mix the mixture, put it into the heated gun mud mixer, dry blend and stir for more than 5 minutes to obtain the mixture;

[0080] The obtained mixture was wet-mixed with 7% gun clay resin with a temperature of 35°C and 4.8% tar with a temperature of 90°C for more than 50 minutes to obtain anhydrous gun clay, and then take the mud to make the Marsha value, the Marsha value 0.8MPa.

[0081] The resulti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com