A kind of magnesium-rare earth alloy with high rolling formability and preparation method thereof

A technology of rare earth alloys and magnesium alloys, applied in the field of magnesium-rare earth alloys with high rolling forming capacity and its preparation, can solve the problems of affecting the hot forming properties of alloys, reducing the elongation of alloys, and unfavorable general applications, etc., so as to achieve easy operation , Conducive to hot rolling processing, high elongation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

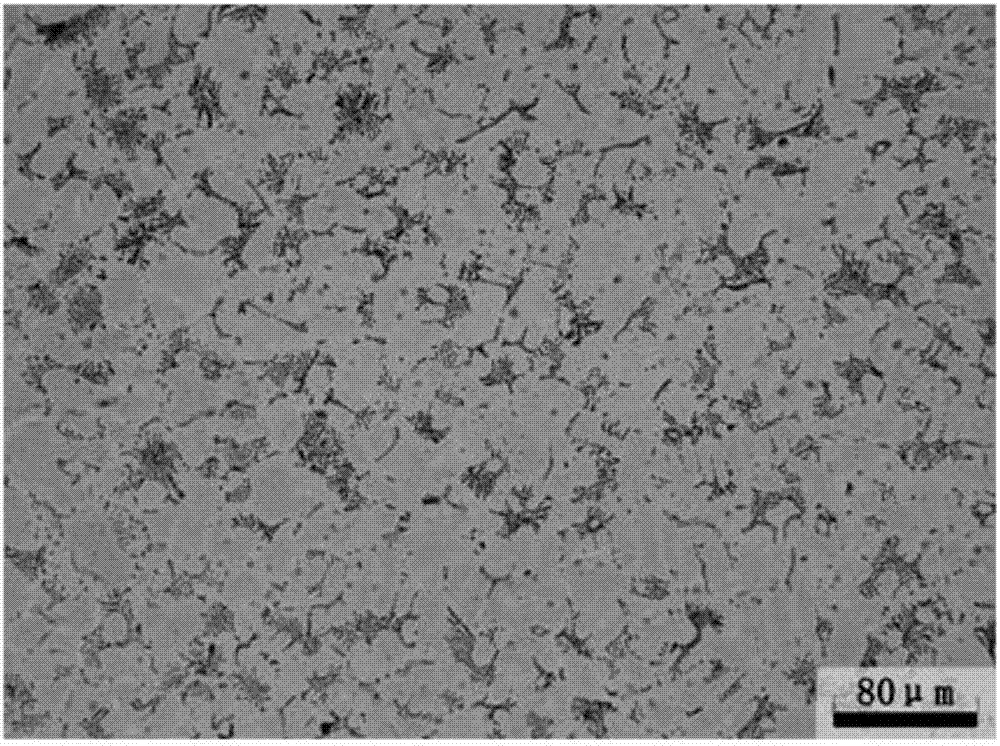

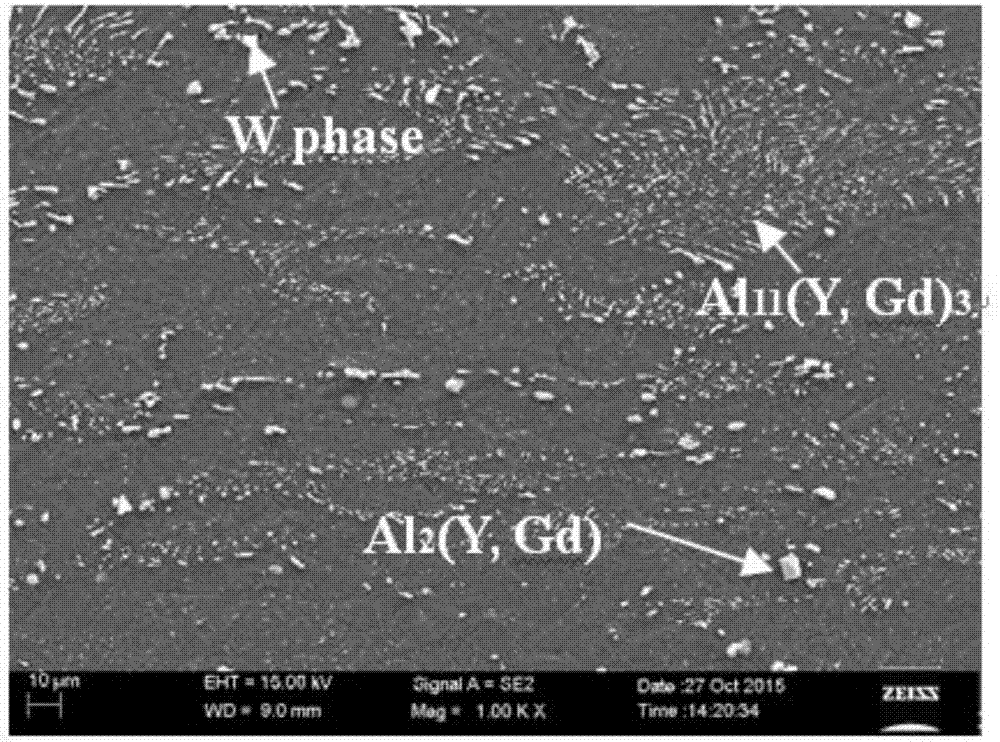

[0023] The chemical composition (mass percentage) of the alloy is: 5.1% Gd, 2.6% Y, 2.1% Zn, 1.0Al, the total amount of impurity elements Fe, Cu, Ni, Si is less than 0.03%, and the balance is Mg.

[0024] The casting and rolling process for preparing the alloy is as follows: first, weigh the material according to the proportion, preheat the Mg, Zn, Al, Mg-Gd master alloy, and Mg-Y master alloy to 200°C, and then put Mg into the preheated to 100°C In the crucible, and into the SF 6 :CO 2 Protective gas with a volume ratio of 1:100, add Zn after the Mg is completely melted, add Mg-Y master alloy and Mg-Gd master alloy when the melt temperature reaches 740°C, and pass in argon after the added master alloy is melted Refining and stirring for 10 minutes, after removing the slag, let it stand at 740°C for 25 minutes, and after the temperature drops to 700°C, cast it into a flat ingot with a metal mold. The resulting slab was air-cooled after homogenization treatment at 450°C for 1...

Embodiment 2

[0026] The chemical composition (mass percentage) of the alloy is: 5.0% Gd, 2.8% Y, 2.0% Zn, 0.9Al, the total amount of impurity elements Fe, Cu, Ni, Si is less than 0.03%, and the balance is Mg.

[0027] The casting and rolling process for preparing the alloy is as follows: first, weigh the materials according to the proportion, preheat Mg, Zn, Al, Mg-Gd master alloy, and Mg-Y master alloy to 200°C, and then put Mg into the In the melting furnace, add Zn and Al after the Mg is completely melted, and add Mg-Gd master alloy and Mg-Y master alloy when the melt temperature reaches 750°C. After the added master alloy is melted, pass in argon gas for refining and stirring for 15 minutes. After removing the slag, let it stand at 740°C for 30 minutes, and after the temperature drops to 720°C, use the electromagnetic continuous casting method to obtain a cylindrical billet. Electromagnetic continuous casting process parameters are: power supply 10kW, power frequency 2000Hz, stable cas...

Embodiment 3

[0029] The chemical composition (mass percentage) of the alloy is: 5.0% Gd, 2.7% Y, 2.0% Zn, 1.0Al, the total amount of impurity elements Fe, Cu, Ni, Si is less than 0.03%, and the balance is Mg.

[0030] The casting and rolling process for preparing the alloy is as follows: first, weigh the materials according to the proportion, preheat Mg, Zn, Al, Mg-Gd master alloy, and Mg-Y master alloy to 200°C, and then put Mg into the In the melting furnace, add Zn and Al after the Mg is completely melted, and add Mg-Gd master alloy and Mg-Y master alloy when the melt temperature reaches 750°C. After the added master alloy is melted, pass in argon gas for refining and stirring for 15 minutes. After removing the slag, let it stand at 740°C for 30 minutes, and after the temperature drops to 720°C, adopt the ordinary continuous casting method to obtain a cylindrical billet. The continuous casting process parameters are: the stable casting rate is 8cm / min, the cooling water volume is 1.5m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com