Wear resistant alloy for high temprature applications

a technology of high temprature and alloy, which is applied in the field of wear-resistant alloy, can solve the problems of mechanical resistance and corrosion resistance, increase the final cost of the valve, and require the use of costly nickel-based superalloys, so as to improve the hot properties of the alloy, increase the chemical affinity, and improve the effect of hot hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

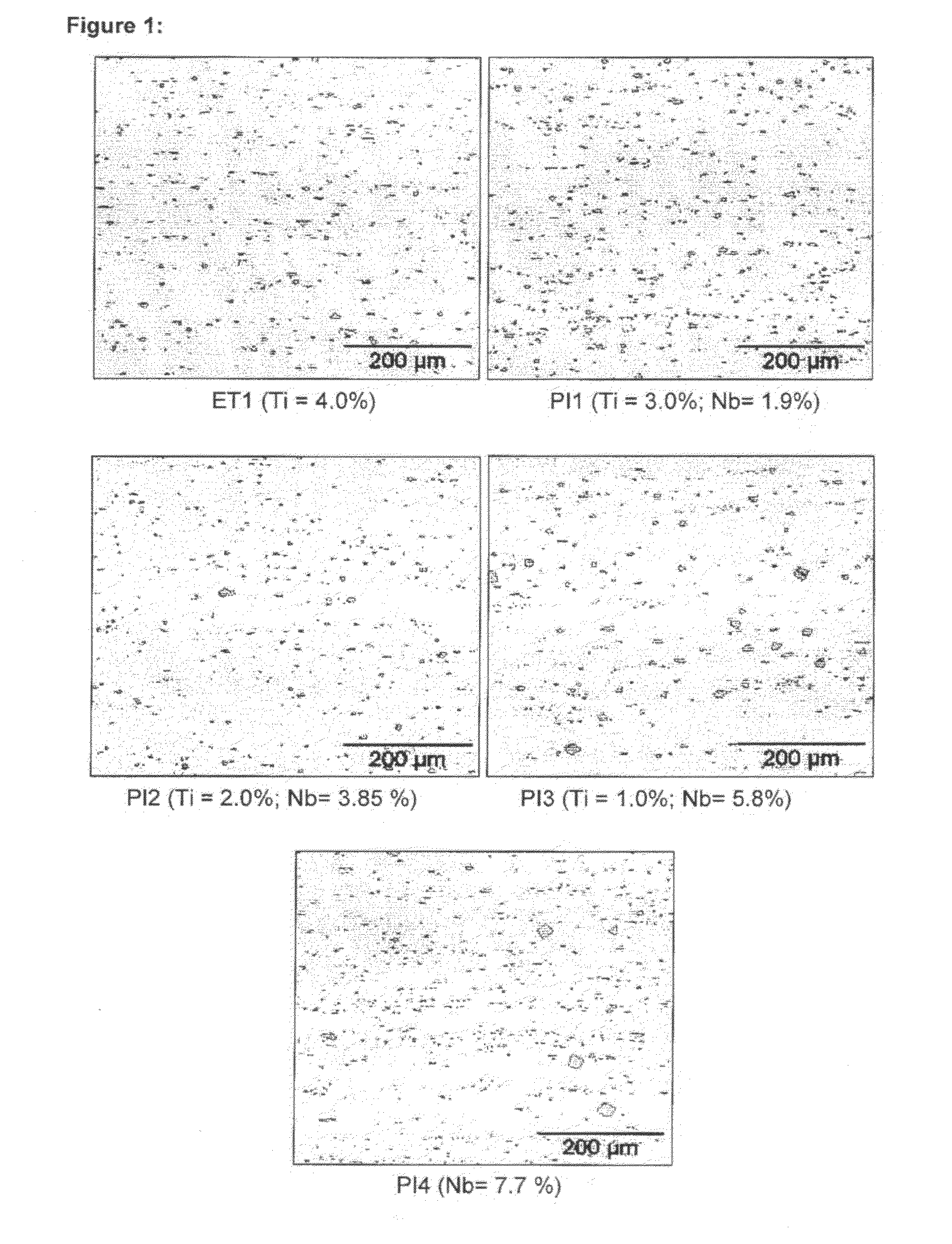

[0045]FIG. 1 shows the microstructure observed in an optical microscope of alloys ET1 and PI1 through PI9, after polishing and attack with Gliceregia reagent for 15 seconds and 120 times magnification.

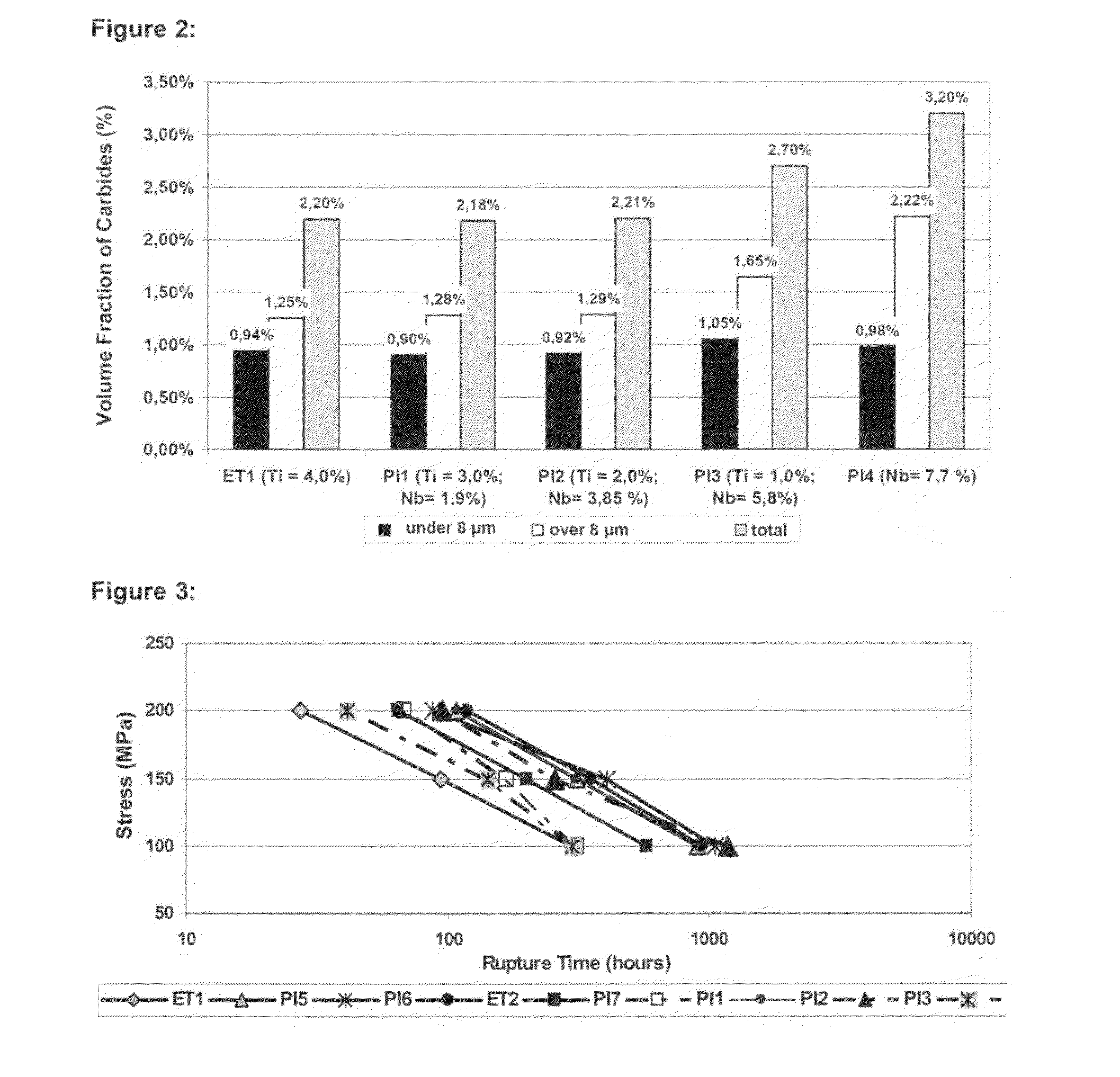

[0046]FIG. 2 shows the result of the image computer analysis to quantify the carbides observed in the alloys studied with different Ti, Nb and Al contents. Such analysis was performed in a total surface area of 65,990,417 μm2 of the sample, in 50 random fields with 500 times magnification.

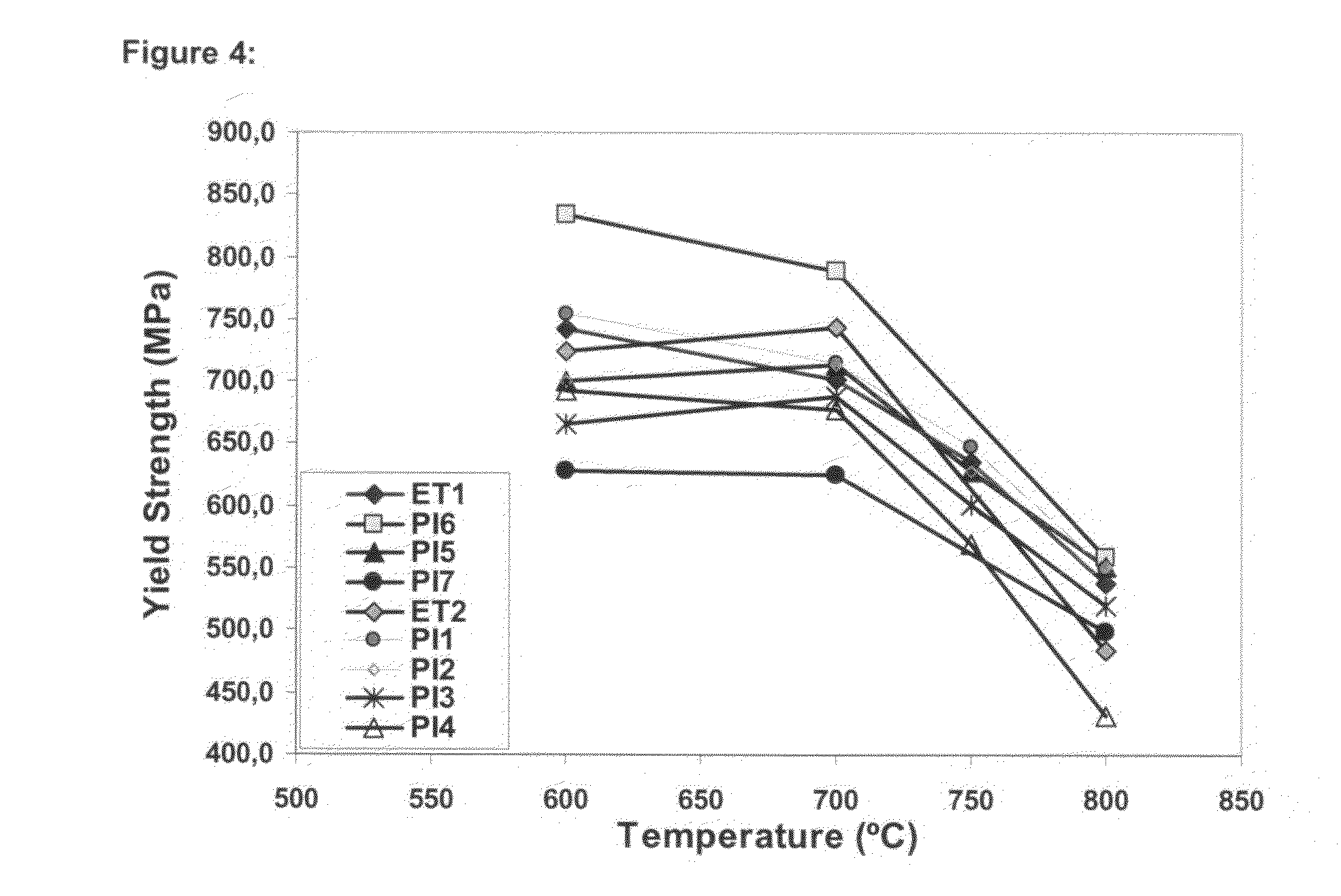

[0047]FIG. 3 shows the results of the creep testing of the alloys hereof as compared to ET1 and ET2 alloys, by assessing the creep rupture time for an 800° C. temperature and 3 tensile stress levels. FIG. 4 compares hot resistance of the alloys hereof to ET1 e ET2 alloys, as of the flow stress for several temperatures.

[0048]FIGS. 5 and 6 show the result of the abrasive wear test carried out with ET1, ET2 alloys and PI1 through PI7 alloys. The test was made by pin against sandpaper; the test specimens ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| contact speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com