400MPa-grade titanium microalloyed hot-rolled steel bar and production method thereof

A technology of microalloying and production method, applied in the field of steel production, can solve the problems of large consumption of precious alloy resources, high content of alloying elements, large fluctuation of product performance, etc. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

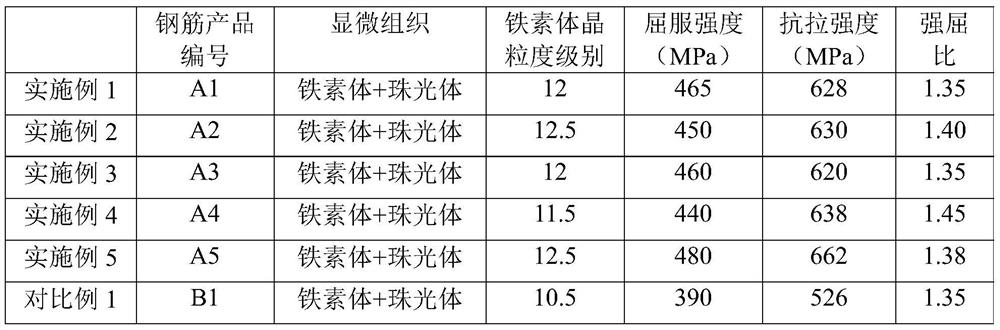

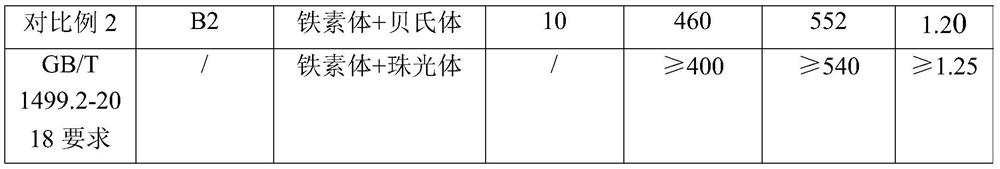

Embodiment 1

[0069] This example is used to illustrate the 400MPa grade titanium microalloyed hot-rolled steel bar and its production method described in the present invention.

[0070] Melt molten iron and scrap steel into molten steel; when the temperature of molten steel reaches 1670°C and the composition of molten steel reaches C: 0.05%, P: 0.02%, and S: 0.03% by mass fraction, the steel is tapped; when the tapping amount is 1 / 3 to 3 During the / 4 process, silicon and manganese are added to the ladle for deoxidation alloying; after tapping is completed, the ladle is transported to the refining station for alloying; first, the composition of molten steel is adjusted to C: 0.24%, Si: 0.52%, Mn: 1.54%; then, add titanium according to the Si and Mn contents of molten steel, and the Ti mass fraction reaches 0.04%, satisfying the relationship (1): [Si]+1.6[Mn]+47.3[Ti]-258.8[Ti] 2 +487.9[Ti] 3 =4.49; Finally, molten steel with qualified composition is obtained; the molten steel with qualifi...

Embodiment 2

[0074] This example is used to illustrate the 400MPa grade titanium microalloyed hot-rolled steel bar and its production method described in the present invention.

[0075] Smelting molten iron into molten steel; when the temperature of molten steel reaches 1680°C and the composition of molten steel reaches C: 0.10%, P: 0.045%, and S: 0.01% by mass fraction, the steel is tapped; during the process of 1 / 3 to 3 / 4 of the tapping amount During the process, silicon and manganese are added to the ladle for deoxidation alloying; during the tapping process, silicon is added to the molten steel for deoxidation; after the tapping is completed, the ladle is transported to the refining station for alloying; Reach C: 0.20%, Si: 0.31%, Mn: 1.0%; then, add ferro-titanium alloy according to Si and Mn content of molten steel, Ti mass fraction reaches 0.1%, satisfying relational formula (1): [Si]+1.6[Mn ]+47.3[Ti]-258.8[Ti] 2 +487.9[Ti] 3 = 4.54; Add Al and Ca cored wires to the molten steel;...

Embodiment 3

[0080] This example is used to illustrate the 400MPa grade titanium microalloyed hot-rolled steel bar and its production method described in the present invention.

[0081] Melt scrap steel into molten steel; when the temperature of molten steel reaches 1620°C and the composition of molten steel reaches C: 0.2%, P: 0.01%, and S: 0.03% by mass fraction, the steel is tapped; when the tapping amount is 1 / 3 to 3 / 4 During the process, silicon and manganese are added to the ladle for deoxidation and alloying; the molten steel after tapping is subjected to LF refining, and the refining time is 35 minutes, and aluminum is added to the molten steel for deoxidation, and the ladle is bottom-blown with argon in the refining station; the molten steel is alloyed , first, adjust the composition of molten steel to reach C: 0.25%, Si: 0.2%, and Mn: 1.23% by mass fraction; then, feed titanium-containing cored wire according to the Si and Mn contents of molten steel, and the mass fraction of Ti r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com