Manufacturing method capable of improving plasticity of pipeline steel plate

A manufacturing method and steel plate technology, which is applied in the field of high-strength steel production, can solve unresolved problems such as yield strength ratio, and achieve the effects of stable production process, strong operability, and improved plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

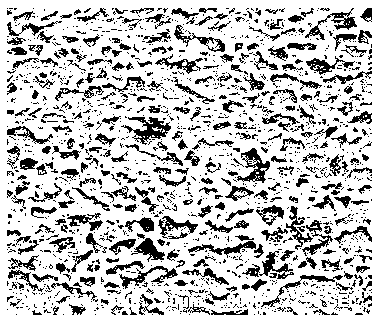

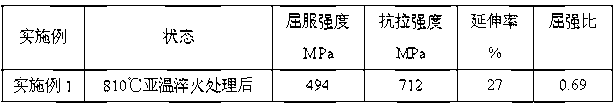

[0020] The product is commercial pipeline steel (thickness 21mm), the chemical composition is shown in Table 1, and the structure is bainite. Reheat to 810°C in the heat treatment furnace, and then hold it at this temperature for 42 minutes. Through the precipitation of Nb, V, N, etc., the loss of yield strength of the steel during heat treatment can be reduced, and the tensile strength can be greatly improved. Quenching, the cooling rate is 18°C / s. The mechanical properties of the treated plate are shown in Table 2, and the microstructure is shown in Table 2. figure 1 , ferrite has a bimodal grain size distribution structure, in which the volume fraction of grains with a diameter below 1 μm accounts for about 50%, the volume fraction of 5-10 μm grains accounts for about 35%, and the volume fraction of grains in the rest size range Fractions account for about 15%.

[0021] Table 1 Chemical composition of pipeline steel in Example 1 (wt%)

[0022] C Si mn P S ...

Embodiment 2

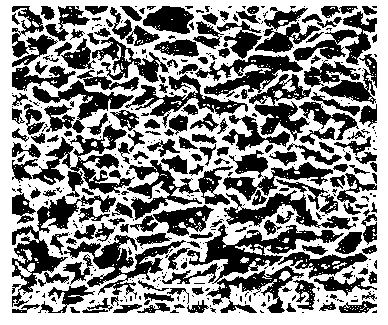

[0026] The product is commercial pipeline steel (plate thickness 21mm), the chemical composition is shown in Table 3, and the structure is bainite. Reheat to 780°C in a heat treatment furnace, then keep it at this temperature for 42 minutes, and cool it by air cooling after the heat preservation is over. The mechanical properties of the treated plate are shown in Table 4, the microstructure figure 2 , ferrite also exhibits a bimodal grain size distribution structure, in which the volume fraction of grains with a diameter below 1 μm accounts for about 55%, the volume fraction of 5-10 μm grains accounts for about 30%, and the volume fraction of grains in the rest size range The volume fraction accounts for about 15%.

[0027] Table 3 The chemical composition (wt%) of the pipeline steel in the example

[0028] C Si mn P S Nb V Ti Cu Cr Ni Al t 0.080 0.25 1.35 0.013 0.0027 0.026 0.020 0.012 0.25 0.15 0.16 0.025

[0029] Table 4 Mec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com